Admixture for shotcrete and preparation method and application thereof

A technology of shotcrete and admixture, which is applied in the field of shotcrete, can solve the problems of poor concrete setting strength and other comprehensive properties, poor improvement effect of concrete cohesion and reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

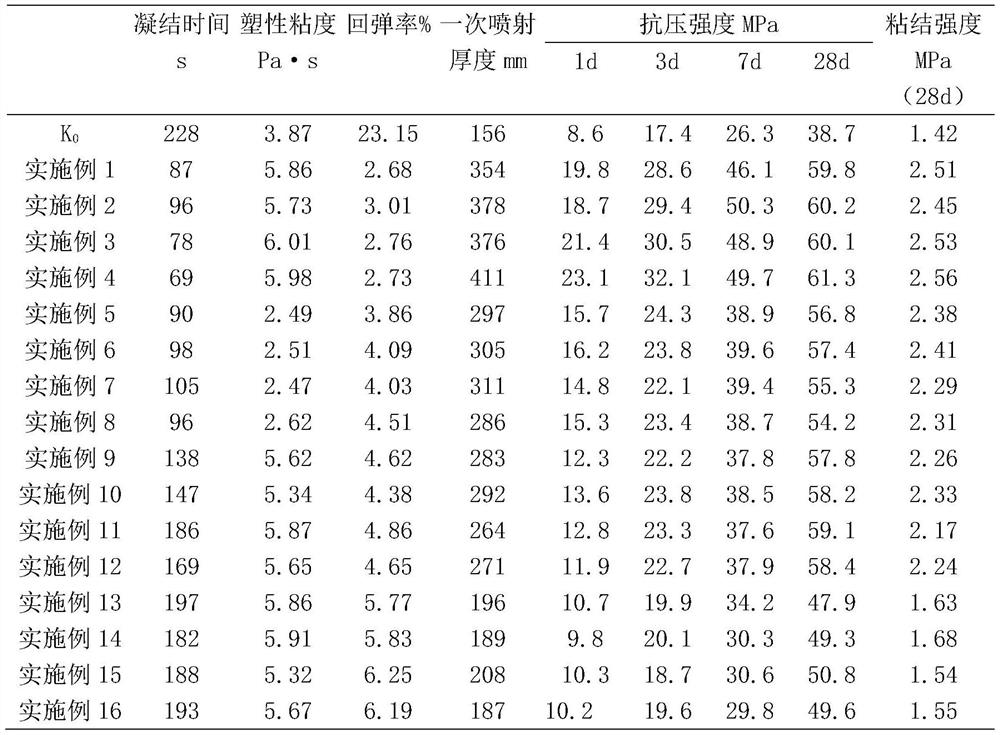

Examples

Embodiment 1

[0026] Admixtures for shotcrete, weigh 0.1kg of modified starch ether (viscosity ≥ 200,000 units), 0.1kg of methyl cellulose propionate, 0.05kg of sodium lauryl sulfate, 0.5kg of carboxylic acid acrylate, mineral The composite powder is 99.25kg; among them, the mineral composite powder is composed of 60kg of limestone powder, 30kg of silica fume and 9.25kg of alumina. Mix directly and stir well.

Embodiment 2

[0028] Admixture for shotcrete, weigh 0.8kg of modified starch ether (viscosity ≥ 200,000 units), 0.8kg of methyl cellulose propionate, 0.12kg of sodium lauryl sulfate, 1kg of carboxylic acid acrylate, mineral compound Powder 97.28kg; Among them, mineral composite powder is compounded by limestone powder 33kg, silica fume 49.28kg and alumina 15kg. Mix directly and stir well.

Embodiment 3

[0030] Admixture for shotcrete, weigh 0.5kg of modified starch ether (viscosity ≥ 200,000 units), 0.4kg of methyl cellulose propionate, 0.1kg of sodium lauryl sulfate, 1kg of carboxylic acid acrylate, mineral compound The powder is 98kg; the mineral composite powder is composed of 33kg of limestone powder, 50kg of silica fume and 15kg of alumina. Mix directly and stir well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com