Treatment method of full-age landfill leachate

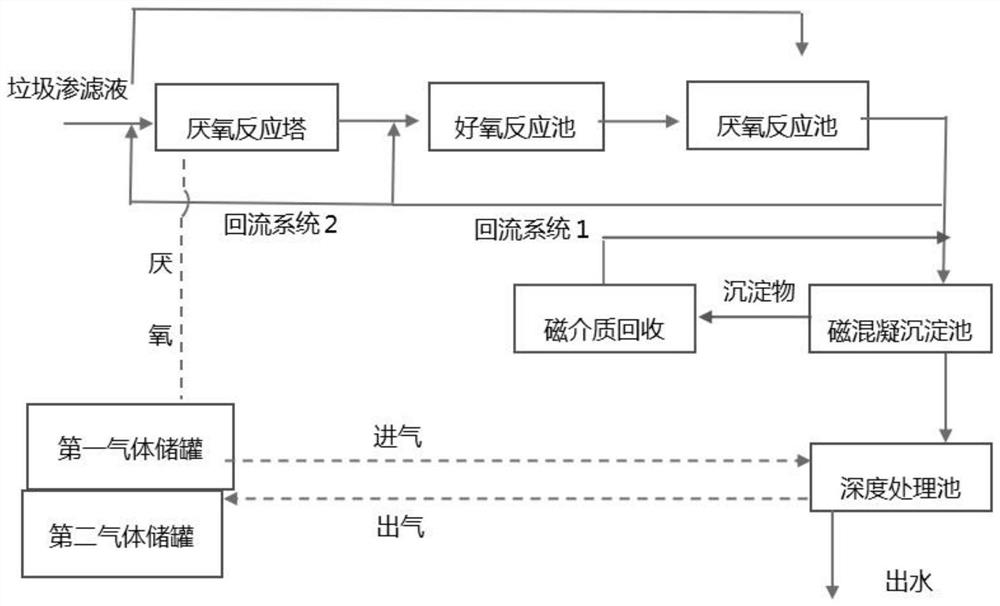

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve the problems of removal effect interference, affecting biological activity, and high reflux ratio of nitrification liquid, so as to avoid interference from other substances, reduce dependence on external carbon sources, The effect of reducing setup and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Treatment of early-age landfill leachate (that is, when the ratio of degradable organic matter to total nitrogen in landfill leachate is ≥6):

[0089] The components of the early landfill leachate: COD 8140~15320mg / L, biochemical oxygen demand (BOD) 7540~14320mg / L, ammonia nitrogen 432~712mg / L, total nitrogen 713~1000mg / L, total phosphorus 15~38mg / L;

[0090] Pass the early landfill leachate into the anaerobic reaction tower for anaerobic methanation treatment to obtain a mixed gas including methane and hydrogen sulfide and the first intermediate product; wherein, the conditions of the anaerobic methanation reaction are temperature 37°C, pH value 7.5, the hydraulic retention time is 18h; the mixed gas is passed into the first gas storage tank for use;

[0091] Pass the first intermediate product into the aerobic reaction tank for nitrosation treatment to obtain the second intermediate product; wherein, the aerobic reaction tank is inoculated with nitrosation activated...

Embodiment 2

[0097] The difference from Example 1 is: the treatment of middle and late age landfill leachate (i.e. when the ratio of degradable organic matter to total nitrogen in the landfill leachate is less than 6):

[0098] The components of the middle and late age landfill leachate: COD 2140-4320mg / L, biochemical oxygen demand (BOD) 1040-2120mg / L, ammonia nitrogen 1400-3120mg / L, total nitrogen 1313-2800mg / L, total phosphorus 18 ~23mg / L;

[0099] The middle and late-age landfill leachate is passed into the anaerobic reaction tower for anaerobic methanation treatment, and a mixed gas including methane and hydrogen sulfide and the first intermediate product are obtained; wherein, the condition of the anaerobic methanation reaction is a temperature of 37°C, The pH value is 7.5, and the hydraulic retention time is 12h; the mixed gas is passed into the first gas storage tank for use;

[0100] Pass the first intermediate product into the aerobic reaction tank for nitrosation treatment to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com