Magnetic super-hydrophobic hollow carbon microsphere as well as preparation method and application thereof

A technology of empty carbon microspheres and superhydrophobic, applied in separation methods, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of cumbersome preparation steps, unreported, narrow application range, etc., and achieve The raw materials are cheap and easy to obtain, the operation is simple and controllable, and the effect of efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

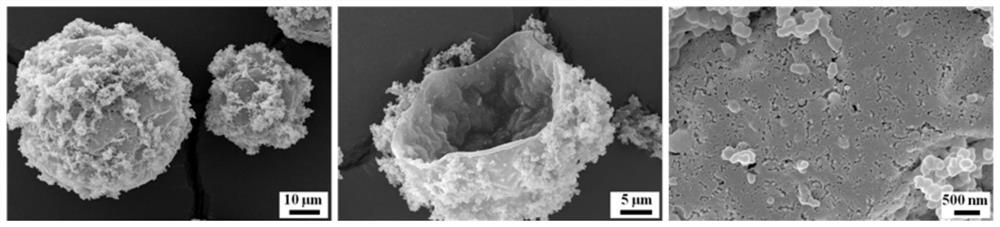

[0035] A preparation method of magnetic super-repellent hollow carbon microspheres, comprising the following steps:

[0036] Step 1: preparing magnetic nanoparticles;

[0037] Step 2: preparing magnetic hollow microspheres by using the magnetic nanoparticles obtained in step 1;

[0038] Step 3: The magnetic hollow microspheres in step 2 are carbonized to obtain the desired magnetic super-repellent hollow carbon microspheres.

[0039] The carbonization process in step 3 is as follows: under atmosphere protection conditions, carbonize at 100-200°C for 15-60 minutes, then at 300-400°C for 15-60 minutes, and finally at 600-1000°C for 1-60 minutes. 4h.

[0040] Step 2 prepares magnetic hollow microspheres by in-situ polymerization or interfacial polymerization.

[0041]When using in-situ polymerization to prepare magnetic hollow microspheres, the wall material is urea-formaldehyde resin, melamine resin, melamine-modified urea-formaldehyde resin, polyvinyl alcohol-modified urea-f...

Embodiment 1

[0063] A preparation method and application of magnetic super-repellent hollow carbon microspheres are as follows:

[0064] Step 1: preparing magnetic nanoparticles;

[0065] Weigh 4.05g ferric chloride hexahydrate, dissolve it in 100mL deionized water, and pass nitrogen; when the temperature of the system rises to 90°C, add 2.7g ferrous sulfate heptahydrate to the above solution, stir and mix evenly; adjust the speed to 600rpm , add 15mL ammonia water (mass percentage concentration is 25-28wt%), react for 5min. Next, 0.67 g of oleic acid was added, and the reaction was continued for 55 minutes before stopping the reaction; the reaction was cooled to room temperature, washed with ethanol and deionized water, and then dried in a vacuum environment at 60° C. to obtain a black powder.

[0066] Step 2: preparing magnetic hollow microspheres by using the magnetic nanoparticles obtained in step 1;

[0067] Weighing 6.33g of formaldehyde solution with a mass concentration of 37wt% ...

Embodiment 2

[0079] A preparation method and application of magnetic super-repellent hollow carbon microspheres are as follows:

[0080] Step 1: preparing magnetic nanoparticles;

[0081] Weigh 4.05g ferric chloride hexahydrate, dissolve it in 100mL deionized water, and pass nitrogen; when the temperature of the system rises to 90°C, add 2.7g ferrous sulfate heptahydrate to the above solution, stir and mix evenly; adjust the speed to 600rpm , add 15mL ammonia water (mass percentage concentration is 25-28wt%), react for 5min. Next, 0.67 g of oleic acid was added, and the reaction was continued for 55 minutes before stopping the reaction; the reaction was cooled to room temperature, washed with ethanol and deionized water, and then dried in a vacuum environment at 60° C. to obtain a black powder.

[0082] Step 2: preparing magnetic hollow microspheres by using the magnetic nanoparticles obtained in step 1;

[0083] Weighing 6.33g of formaldehyde solution with a mass concentration of 37wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com