Positive electrode material as well as preparation method and application thereof

A positive electrode material, aluminum tripolyphosphate technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, battery electrodes, etc., can solve problems such as high temperature storage, temperature rise, and inability to use. Achieve the effects of improving high temperature storage performance, reducing surface alkali content, inhibiting decomposition and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

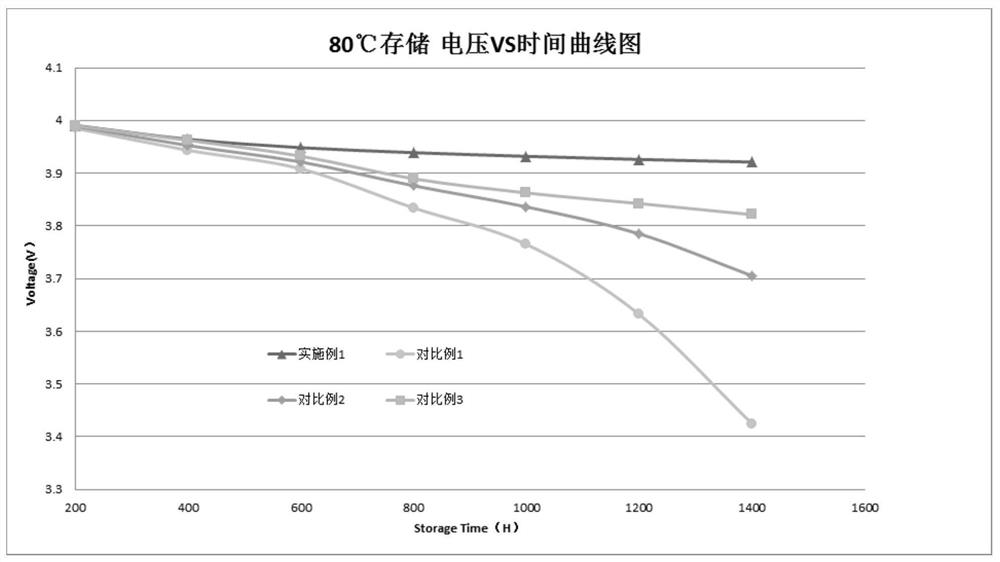

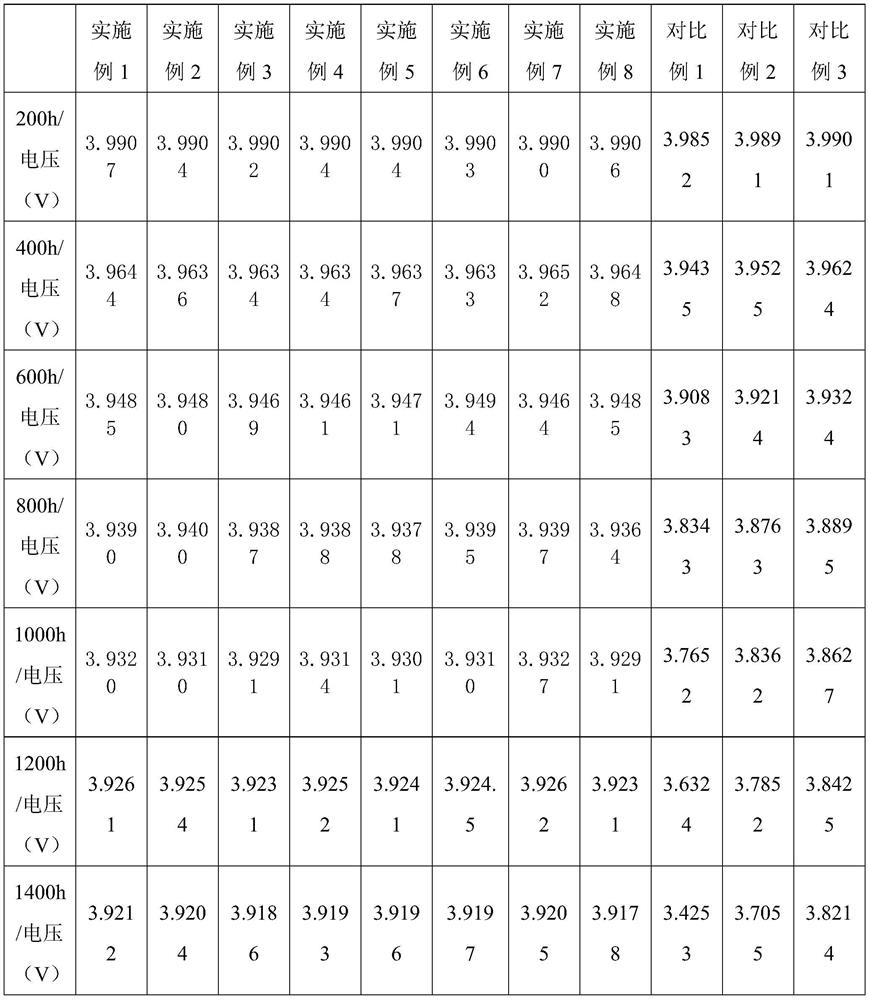

Examples

Embodiment 1

[0069] A kind of cathode material, its preparation method comprises the following steps:

[0070] (1) The aluminum tripolyphosphate powder with a particle size of 2nm and the nickel-cobalt-manganese ternary positive electrode material (NCM811) are ball milled and dry mixed, wherein the total mass of the aluminum tripolyphosphate powder and the nickel-cobalt-manganese ternary positive electrode material In terms of 100%, the mass fraction of aluminum tripolyphosphate powder is 0.1%, the ball-to-material ratio in ball milling dry mixing is 1.5:1, the size of large balls used in ball milling is 4mm, the size of small balls is 2mm, and the ball milling time is 5min. The positive electrode material premix is ready for use;

[0071] (2) First prepare colloidal silica sol, the solution concentration is 5% sodium silicate aqueous solution, add excess CO 2 , making a colloidal silica sol with a net amount of silicon of 0.1%, mixing the colloidal silica sol with the positive electrod...

Embodiment 2

[0076] A kind of cathode material, its preparation method comprises the following steps:

[0077] (1) The aluminum tripolyphosphate powder with a particle size of 20nm is mixed with the nickel-cobalt-manganese ternary positive electrode material (NCM811), wherein the total mass of the aluminum tripolyphosphate powder and the nickel-cobalt-manganese ternary positive electrode material is In terms of 100%, the mass fraction of aluminum tripolyphosphate powder is 1%, the ball-to-material ratio in ball milling dry mixing is 1.5:1, the size of large ball particles used in ball milling is 4mm, the size of small ball particles is 2mm, and the ball milling time is 5min to form a positive electrode Material premix ready for use;

[0078] (2) First prepare colloidal silica sol, the solution concentration is 25% sodium silicate aqueous solution, add excessive CO 2 , making a colloidal silica sol with a net amount of silicon of 1%, mixing the colloidal silica sol with the positive electr...

Embodiment 3

[0084] A kind of cathode material, its preparation method comprises the following steps:

[0085] (1) The aluminum tripolyphosphate powder with a particle size of 10nm is mixed with the nickel-cobalt-manganese ternary positive electrode material (NCM811), wherein the total mass of the aluminum tripolyphosphate powder and the nickel-cobalt-manganese ternary positive electrode material is In terms of 100%, the mass fraction of aluminum tripolyphosphate powder is 0.5%, the ball-to-material ratio in ball milling dry mixing is 1.5:1, the size of large ball particles used in ball milling is 4mm, the size of small ball particles is 2mm, and the ball milling time is 5min to form a positive electrode Material premix ready for use;

[0086] (2) Prepare colloidal silica sol earlier, dissolve concentration and be 10% sodium silicate aqueous solution, add excessive hydrochloric acid, make the colloidal silica sol that silicon net amount is 0.5%, colloidal silica The sol is mixed with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com