Method for refining ionic membrane caustic soda primary refined brine

A technology of ionic membrane caustic soda and refined brine, applied in the direction of alkali metal chloride, alkali metal halide purification, electrolytic components, etc., can solve the problems of high cost, membrane tube blockage, restriction, etc., and achieve low energy consumption and membrane flux The effect of large and small transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

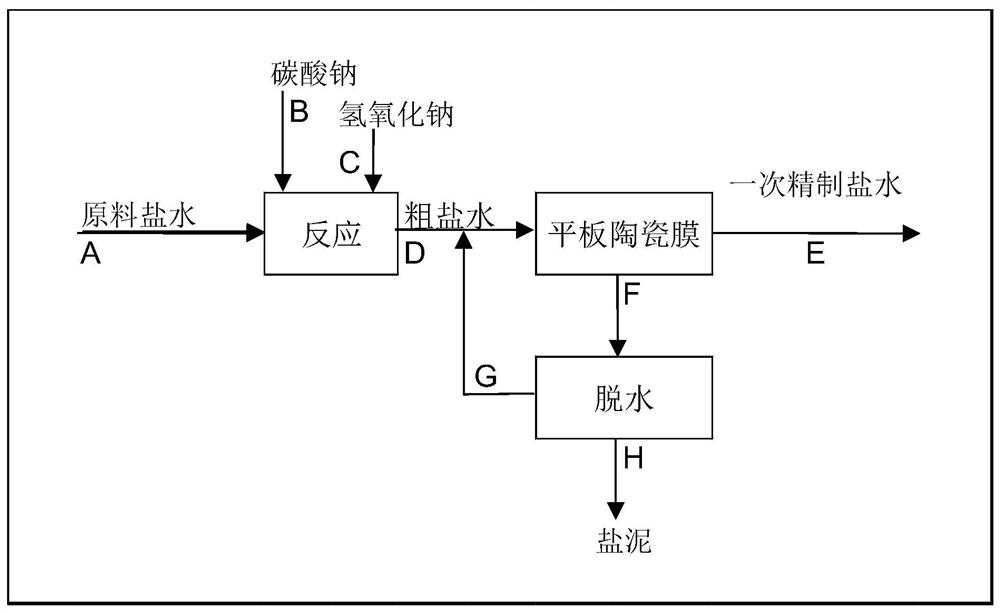

[0047] Improvement Pilot Test of Primary Refined Brine in a Chlor-Alkali Enterprise

[0048] The existing ionic membrane caustic soda primary brine refining system adopts pre-reaction adding sodium hydroxide to remove magnesium, floating clarifier tank as pretreatment of coarse brine, post-reaction adding sodium carbonate to remove calcium, and PTFE organic membrane filtration to remove the water-insoluble matter formed by the reaction. Process, calcium and magnesium dosing to control the over-alkaline amount of sodium hydroxide and sodium carbonate, so that the refined brine is alkaline, pH is about 10.5-11.5, sodium hydroxide is about 0.1-0.3g / L; sodium carbonate is about 0.3-0.5g / L, the pretreatment of this existing process is the need for the purification of PTFE organic membrane filtration. Without floating clarification pretreatment, the flow rate of PTFE organic membrane filtration fluctuates greatly, and the output of refined brine cannot be stably guaranteed to meet t...

Embodiment 2

[0066] A chemical plant adopts nanofiltration membrane salt separation, reverse osmosis membrane concentration, and evaporation salt extraction processes in the zero-discharge treatment of high-salt inorganic wastewater. The sodium chloride in the wastewater is 10g / L, and the Ca 2+ About 500mg / L, Mg 2+ About 100mg / L, sulfate about 5000mg / L. In order to avoid the impact of calcium sulfate scaling on nanofiltration membranes, reverse osmosis membranes and evaporation equipment caused by the concentration and enrichment of calcium magnesium ions and sulfate radicals, it was decided to use dosing reaction and membrane separation of magnesium hydroxide and calcium carbonate as nanofiltration Membrane pretreatment experiments.

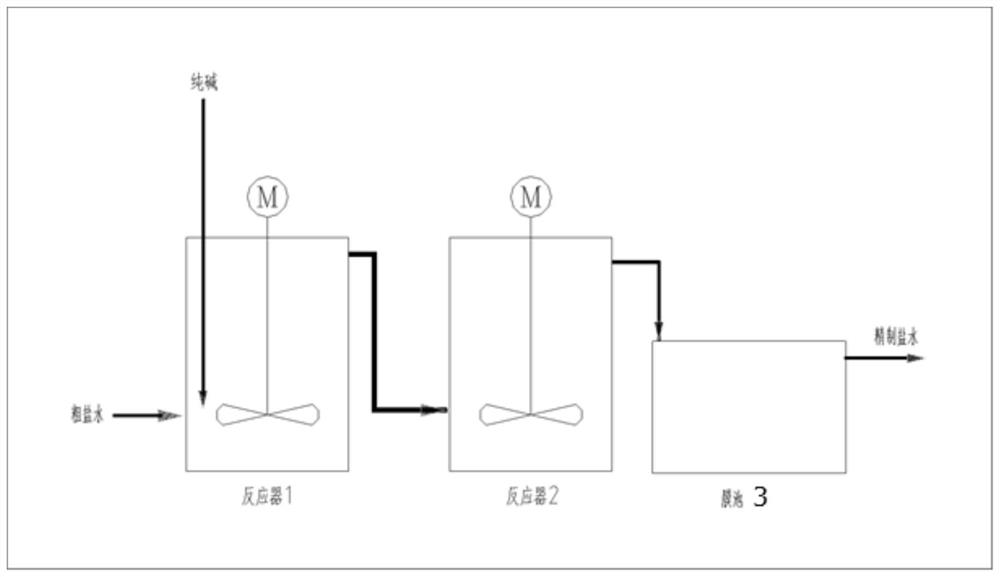

[0067] The experiment adopts the reaction of adding sodium hydroxide and sodium carbonate under normal temperature conditions to react calcium and magnesium ions into magnesium hydroxide and calcium carbonate solids, and separate solid and liquid through fl...

Embodiment 3

[0083] Sodium chlorate production of brine refining currently adopts the refining process of Doyle clarifier + sand filter + carbon tube filtration, which has the characteristics of long process, large investment, high labor intensity, difficult management, and poor quality of brine. The refined brine In general Ca 2+ +Mg 2+ All around 10mg / L, SS>5mg / L.

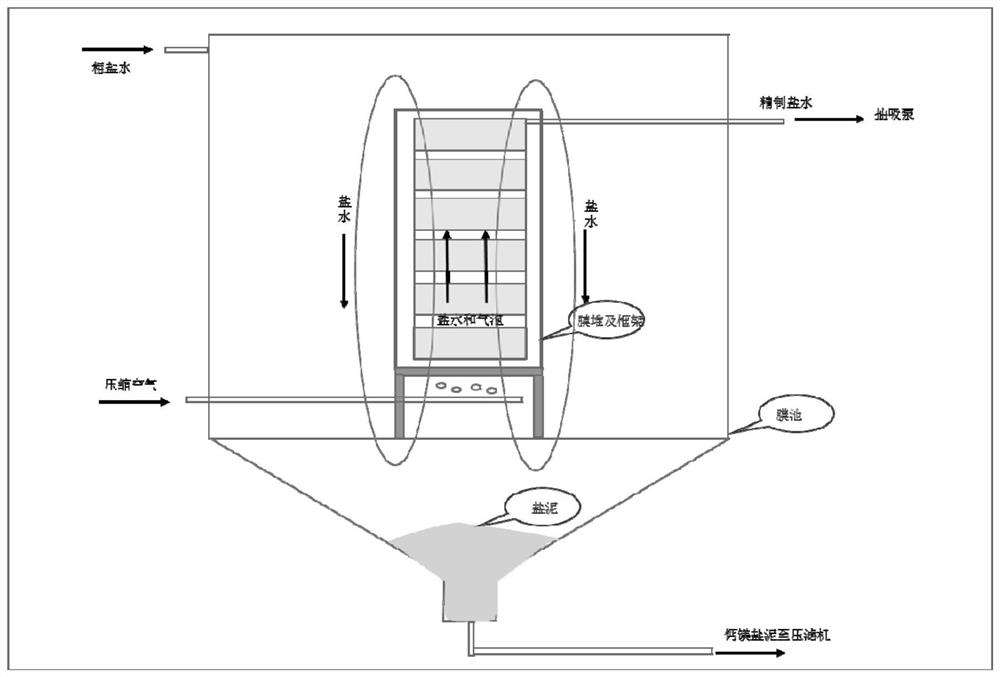

[0084] The existing sodium chlorate brine is filtered and refined, with a processing capacity of 45m 3 / h, sodium chloride in raw brine is 100g / L, sodium chlorate is 530g / L, Ca 2+ +Mg 2+ It is 100mg / L, containing a small amount of iron filings, etc. Using sodium hydroxide to remove magnesium, sodium carbonate to remove calcium, and flat ceramic membrane filtration refining process, the production requires Ca in the purified liquid 2+ +Mg 2+ Not more than 1mg / L, and the water-insoluble (SS) content is not more than 1mg / L. The specific method is as follows:

[0085] (1) The concentration of each component of sodium chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com