Ultra-light C/C-SiC space reflector and preparation method and application thereof

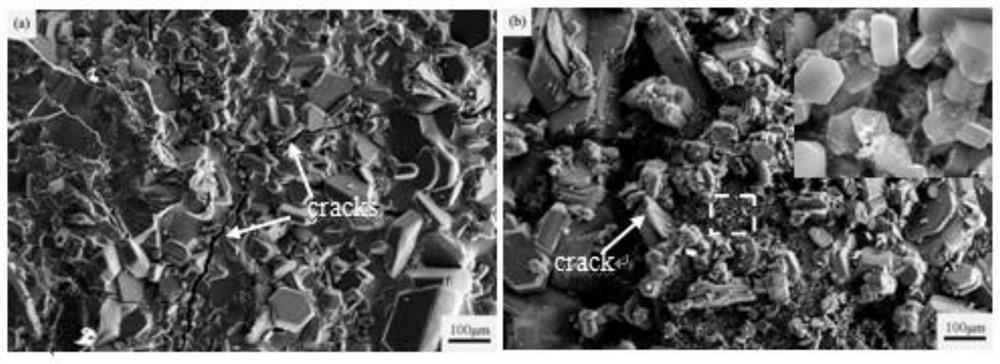

A mirror, ultra-light technology, applied in the field of chemical materials, can solve the problems of large surface roughness, no successful application, etc., to achieve good quality, improve anti-oxidation and thermal shock resistance, and reduce cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

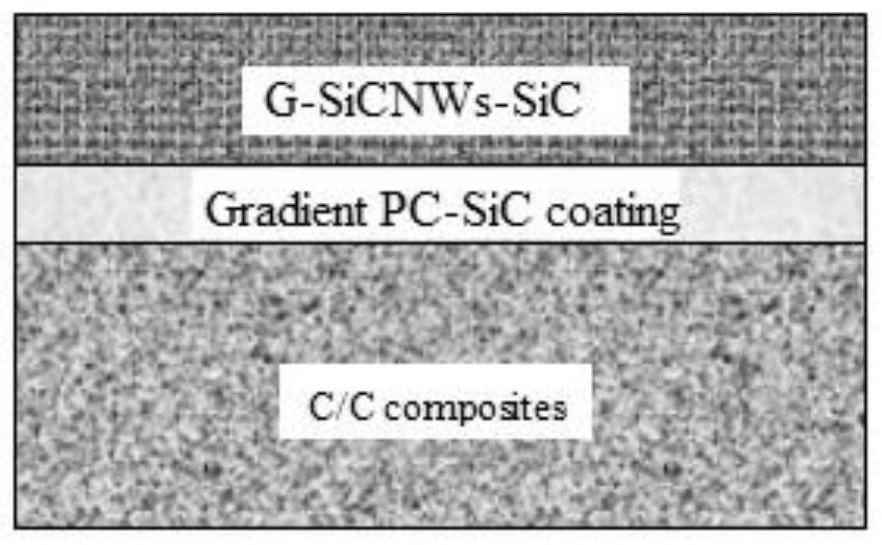

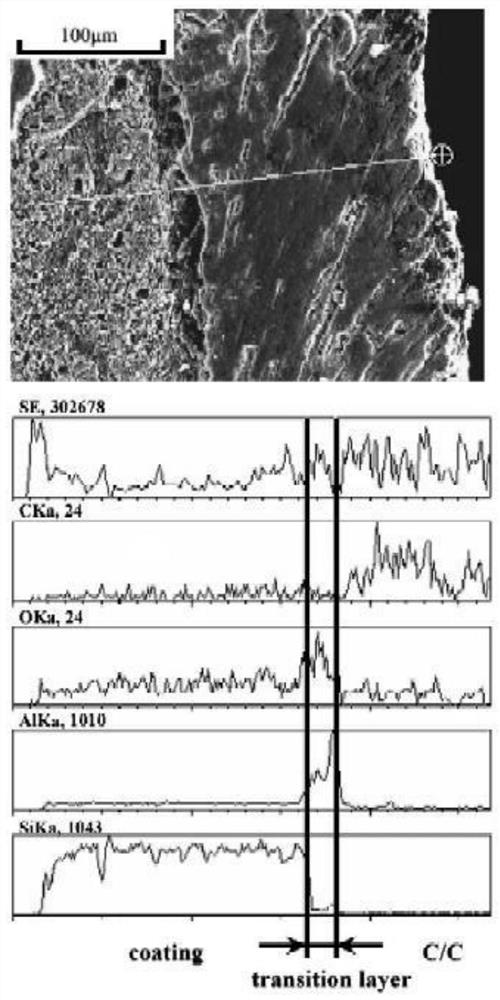

[0050]Such asfigure 1 As shown, this embodiment discloses an ultra-lightweight C / C-SiC space mirror, including a C / C composite material, a SiC gradient transition layer embedded on the surface of the C / C composite material, and a SiC gradient transition layer. The graphene-SiCNWs multi-dimensional hybrid enhanced CVD-SiC coating on the surface of the layer; the SiC gradient transition layer is abbreviated as PC-SiC, and the graphene-SiCNWs multi-dimensional hybrid enhanced CVD-SiC coating is abbreviated as G-SiCNWs- SiC, the graphene is abbreviated as G, and the SiCNWs are SiC nanowires.

[0051]This embodiment also discloses a method for preparing an ultra-lightweight C / C-SiC space mirror, which includes the following steps:

[0052](1) SiC gradient transition layer embedding method can be controlled

[0053]Take C powder and Si powder as main raw materials, add a small amount of Al2O3Permeation enhancer and ferrocene modifier, which are mixed powders, are embedded in the C / C composite mate...

Embodiment 2

[0070]An ultra-lightweight C / C-SiC space mirror, including C / C composite material, SiC gradient transition layer embedded on the surface of the C / C composite material, and graphene-SiCNWs multidimensional arranged on the surface of the SiC gradient transition layer Hybrid enhanced CVD-SiC coating; the SiC gradient transition layer is abbreviated as PC-SiC, the graphene-SiCNWs multi-dimensional hybrid enhanced CVD-SiC coating is abbreviated as G-SiCNWs-SiC, and the graphene is abbreviated as G, the SiCNWs are SiC nanowires.

[0071]The content of silicon in the SiC gradient transition layer gradually increases from the inside of the C / C composite material to the outer surface of the G-SiCNWs-SiC.

[0072]A preparation method of ultra-lightweight C / C-SiC space mirror includes the following steps:

[0073]S1, the embedding method can control the preparation of SiC gradient transition layer:

[0074]Embed the sample of C / C composite material in the mixed powder, the mixed powder includes C powder, ...

Embodiment 3

[0083]The difference between this embodiment and Embodiment 2 is only:

[0084]A preparation method of ultra-lightweight C / C-SiC space mirror includes the following steps:

[0085]S1, the embedding method can control the preparation of SiC gradient transition layer:

[0086]Embed the sample of C / C composite material in the mixed powder, the mixed powder includes C powder, Si powder, MgO penetration enhancer and ferrocene modifier; the mass ratio of C powder and Si powder is 3:1 , MgO penetration enhancer accounts for 8% by mass in the mixed powder, and ferrocene modifier accounts for 10% by mass in the mixed powder; after embedding, it is heated and reacted at a temperature of 2300°C for 3 hours to obtain a uniform structure SiC gradient transition layer, namely PC-SiC;

[0087]S2, G-SiCNWs can be prepared on the surface of PC-SiC:

[0088]Place the PC-SiC in the reaction zone of the CVD furnace, and then pass in H after vacuuming2And Ar, when the temperature of the reaction zone reaches the depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com