A method for preparing broadband reflective cholesteric liquid crystal thin films by photothermal response technology

A cholesteric liquid crystal, photothermal response technology, used in optics, nonlinear optics, instruments, etc., to achieve the effects of low price, excellent photothermal conversion performance, and flexible heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

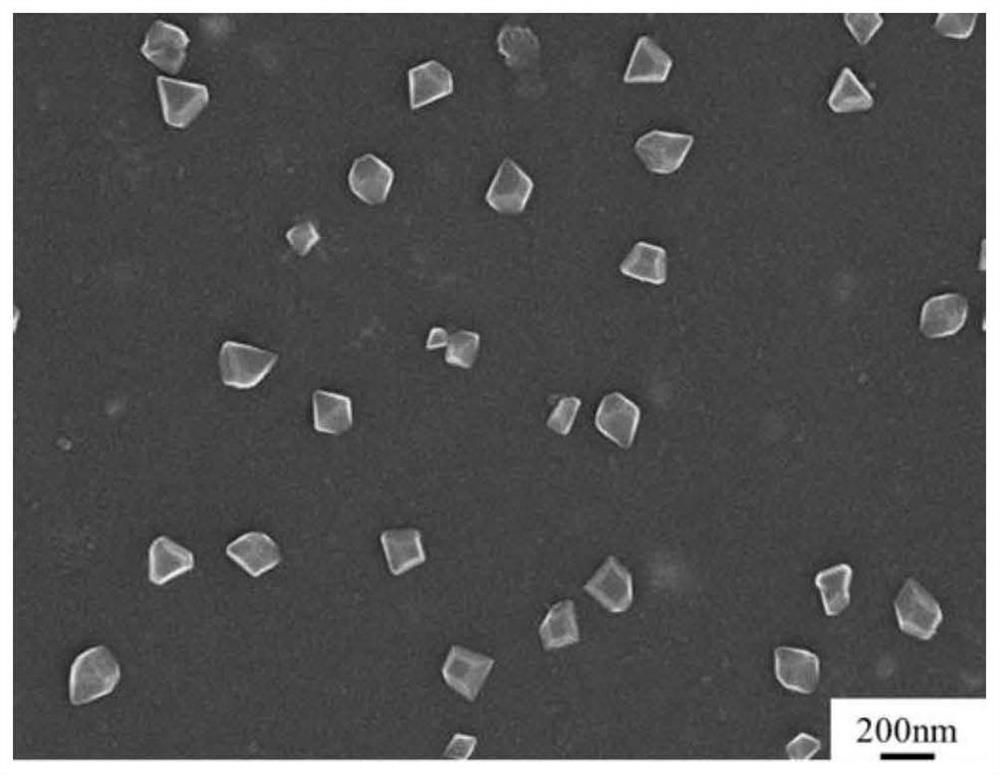

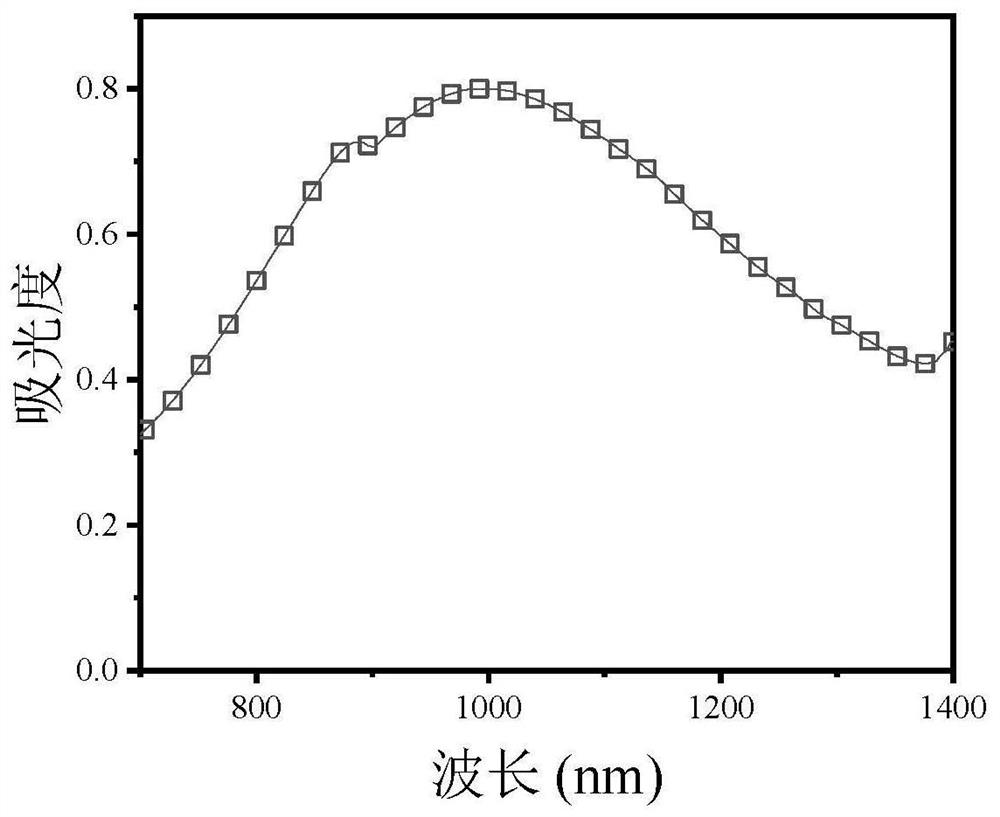

[0026] Production of the liquid crystal cell: Cut the glass coated with indium tin oxide on one side into a size of 2cm×3cm, wash it twice with washing powder, clean water twice, once with deionized water and ethanol, and place it in a clean glass petri dish. Wait for the glass to dry naturally. Dissolve 4g of polyvinyl alcohol in 200mL of water, heat to 90°C to dissolve, and 84mg of copper dichloride hydrate (CuCl 2 .2H 2 O) was dissolved in 40mL water, and the resulting solution was added into the polyvinyl alcohol solution under stirring, and stirred for 4h to make it fully complexed; 41.56mg of anhydrous sodium sulfide (Na 2 S) Dissolve in 20 mL of water, add the obtained solution into the reaction system, and react for 15 minutes to obtain a light green aqueous solution of polyvinyl alcohol-modified copper sulfide nanoparticles. Drop-coat 0.25mL of the prepared polyvinyl alcohol-modified copper sulfide nanoparticle solution on a glass slide, and dry it on a hot table at...

Embodiment 2

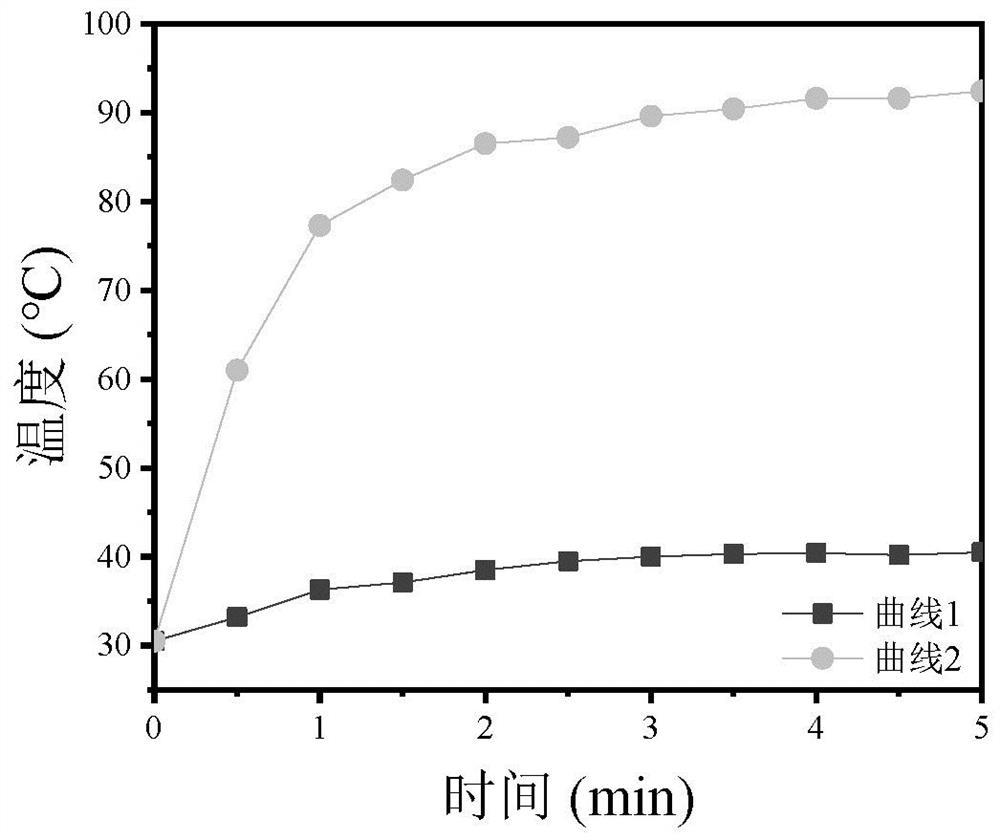

[0036] Using the same liquid crystal cell manufacturing process and sample formula as in Example 1, the cholesteric liquid crystal system was poured into the liquid crystal cell. After the system is stable, place the liquid crystal cell under a near-infrared laser with a wavelength of 980nm at a distance of 18cm, and adjust the intensity of the near-infrared laser to 0.5-2.4W / cm 2 , stay at each intensity for 1min, a total of 20min. In this 20min, the use intensity is 0.5mW / cm 2 The ultraviolet light is irradiated on the sample at the same time, so that the polymerizable monomer C6M in the cholesteric liquid crystal is polymerized to form a network, and the pitch of each temperature section is fixed.

Embodiment 3

[0038] Using the same liquid crystal cell manufacturing process and sample formula as in Example 1, the cholesteric liquid crystal system was poured into the liquid crystal cell. After the system is stable, place the liquid crystal cell under a near-infrared laser with a wavelength of 980nm at a distance of 18cm, and adjust the intensity of the near-infrared laser to 0.5-2.4W / cm 2 , stay at each intensity for 1min, a total of 20min. In this 20min, the use intensity is 1mW / cm 2 The ultraviolet light is irradiated on the sample at the same time, so that the polymerizable monomer C6M in the cholesteric liquid crystal is polymerized to form a network, and the pitch of each temperature section is fixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com