Zinc-air battery and preparation method and application thereof

A technology of air batteries and precursors, applied to battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the problems of metal particle agglomeration, uneven dispersion, and CNT tube diameters. problems, to achieve the effect of large specific surface area, not easy to oxidize, and unique preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

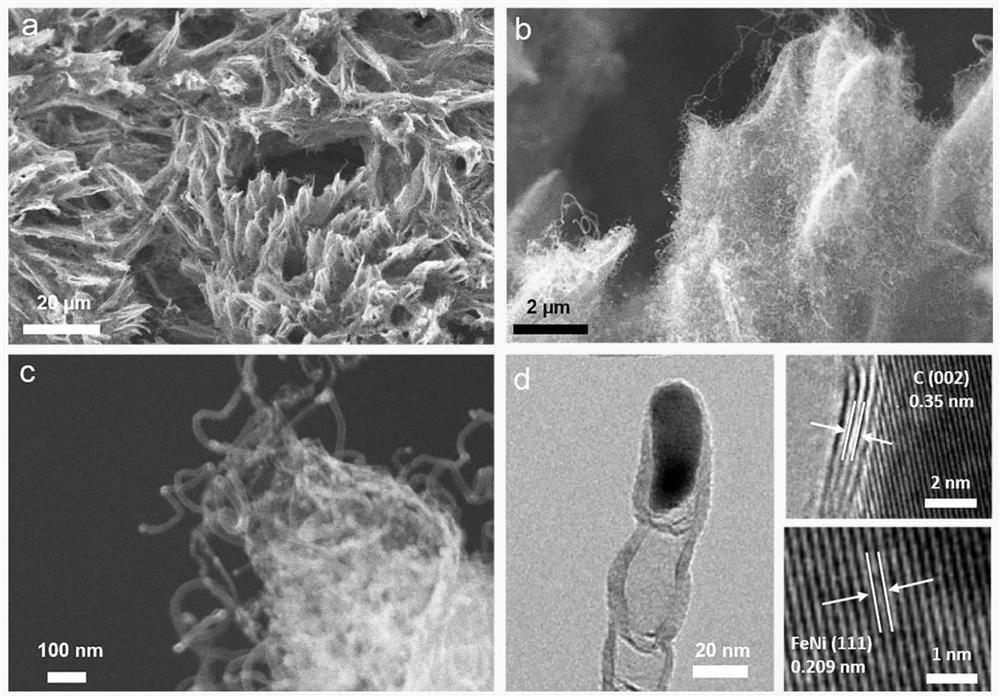

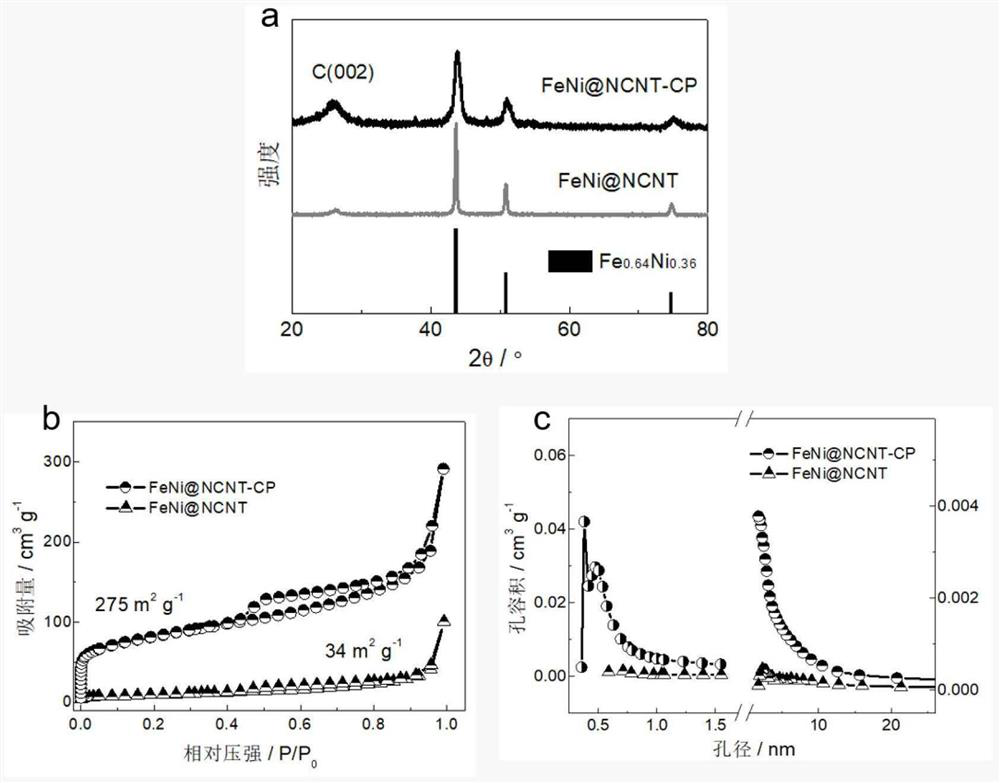

[0030]Preparation of the precursor mixture: 3 g of urea (CO(NH2)2), 0.105 g of iron nitrate nonahydrate (Fe(NO3)3·9H2O), 0.075 g nickel nitrate hexahydrate (Ni(NO3)2·6H2O) and 20 mL of ultrapure water were added to the beaker, and dissolved under normal stirring at room temperature; then the beaker was transferred to the refrigerator to freeze at -18°C for 12 h, and then freeze-dried in a freeze dryer at -50°C for 24 h to obtain Precursor mixture powder containing C, N, Fe, and Ni.

[0031]Fill the small corundum boat with the above precursor mixture powder, and buckle it upside down in the middle of the big corundum boat; then put two clean 2*5 cm pieces2The cotton pieces are placed on the vacant parts of the large corundum boat at both ends, and contact the outer side of the small corundum boat.

[0032]At room temperature, transfer the above-mentioned upside-down corundum boat assembly with cotton cloth to the middle of the tube furnace, and calcinate in a nitrogen atmosphere at 10 ℃ / m...

Embodiment 1

[0038]The liquid zinc-air battery is composed of carbon paper with electrocatalyst as the air electrode, metal Zn sheet as the negative electrode, and 6.0 M KOH aqueous solution containing 0.2 M zinc acetate as the electrolyte. The electrocatalyst is dripped onto the carbon paper with a loading amount of 1.0 mg cm-2Specifically, 4 mg of three-dimensional carbon nanotube jungle, 1 mg of acetylene black, 50 μL of adhesive Nafion, and 2 mL of ethanol were mixed and dropped on carbon paper, and dried in a conventional environment to obtain an air electrode. Assemble the two electrode sheets with three different acrylic plates and screws into a liquid-box battery. The performance of the zinc-air battery is mainly carried out on the Landian LANDCT2001A. The constant current discharge curve can be obtained by testing the relationship between voltage and time at a constant current density, and charging and discharging can be obtained by repeated charging and discharging at a fixed capacity....

Embodiment 2

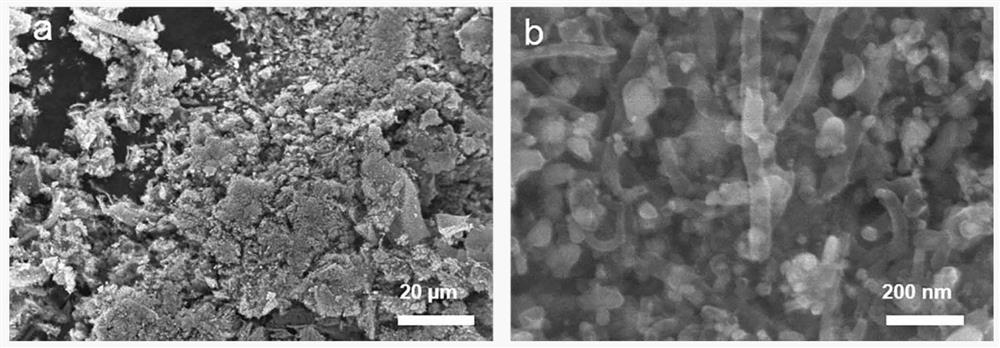

[0051]Preparation of the precursor mixture: 3 g of urea (CO(NH2)2), 0.105 g of iron nitrate nonahydrate (Fe(NO3)3·9H2O), 0.075 g nickel nitrate hexahydrate (Ni(NO3)2·6H2O) and 20 mL of ultrapure water were added to the beaker, and dissolved under normal stirring at room temperature; then the beaker was transferred to the refrigerator to freeze at -18°C for 12 h, and then freeze-dried in a freeze dryer at -50°C for 24 h to obtain Precursor mixture powder containing C, N, Fe, and Ni.

[0052]Fill the small corundum boat with the above precursor mixture powder, and buckle it upside down in the middle of the big corundum boat; then put two clean 2*5 cm pieces2The cotton pieces are placed on the vacant parts of the large corundum boat at both ends, and contact the outer side of the small corundum boat.

[0053]At room temperature, transfer the above-mentioned upside-down corundum boat assembly with cotton cloth to the middle of the tube furnace, and calcinate in a nitrogen atmosphere at 2.5 ℃ / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com