A preparation method of organic-inorganic hybrid porous material for separating propylene propane

A porous material, propylene propane technology, applied in organic chemistry, chemical instruments and methods, adsorption purification/separation, etc., can solve the problems of difficult separation, low relative volatility, etc., achieve simple preparation process, low equipment requirements, high The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of an organic-inorganic hybrid porous material for separating propylene propane, comprising the following steps:

[0034] 1) Put nickel hydroxide in a container, and then dropwise add an aqueous solution of hexafluorosilicic acid with a concentration of 20-30 wt%, the molar ratio of nickel hydroxide and hexafluorosilicic acid is 1.1-1.3:1; stirring reaction at room temperature 3 -5h, the obtained reaction product was suction filtered to obtain a green solution and dried at 40-60°C to obtain green nickel salt crystals.

[0035]2) Add 2-mercaptopyrazine into methanol according to the solid-liquid ratio of 0.1-0.15g / 10-30mL, and ultrasonicate for 20-40min to completely dissolve 2-mercaptopyrazine to obtain solution A; Liquid ratio 0.14-0.16g / 6-10mL is dissolved in methanol solution to obtain solution B; after solution A and solution B are mixed, add in the reactor, the mol ratio of described 2-mercaptopyrazine and green nickel salt crystal is ( 1-2): ...

Embodiment 1

[0038] Preparation of Nickel Hexafluorosilicate:

[0039] Weigh 4.2 g of nickel hydroxide into a 100 mL round-bottomed flask, then add 20 mL of a 25wt% hexafluorosilicic acid aqueous solution, wherein the molar ratio of hexafluorosilicic acid and nickel hydroxide is 1:1.1, and the reaction is stirred at room temperature for 4 h. The green solution was obtained by suction filtration with a Buchner funnel, and dried at 50° C. to remove water to obtain green hexafluorosilicate crystals, which were used for later use.

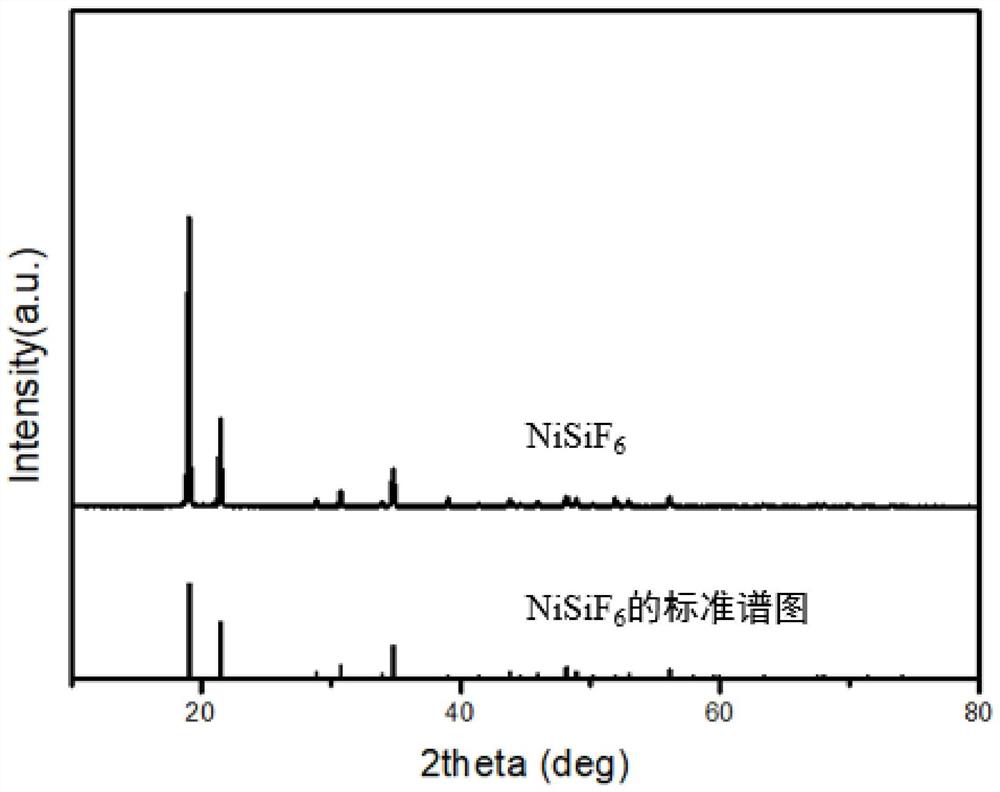

[0040] Embodiment 1 prepares the above-mentioned method of nickel hexafluorosilicate is optimal condition, as figure 1 As shown, it has high phase purity, and the nickel hexafluorosilicate in the subsequent examples is prepared by the above method.

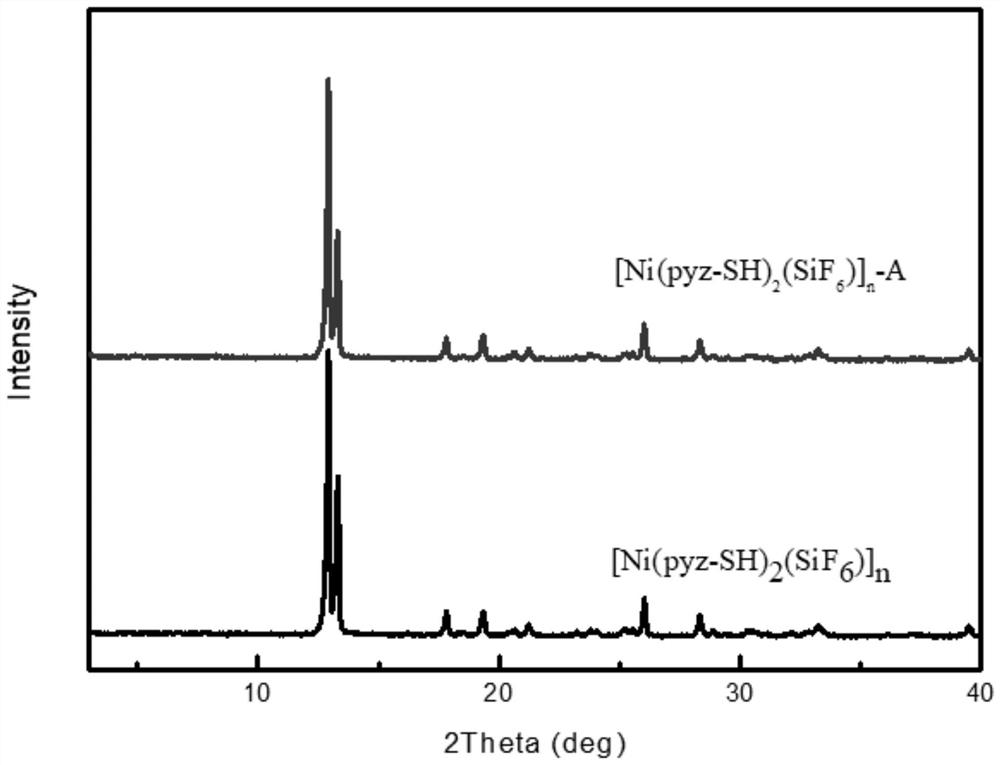

[0041] Organic-inorganic hybrid porous materials [Ni(pyz-SH) 2 (SiF 6 )] n Preparation and activation of:

[0042] Dissolve 0.154g of nickel hexafluorosilicate in 6mL of methanol solution and 0.112g of organic lig...

Embodiment 2

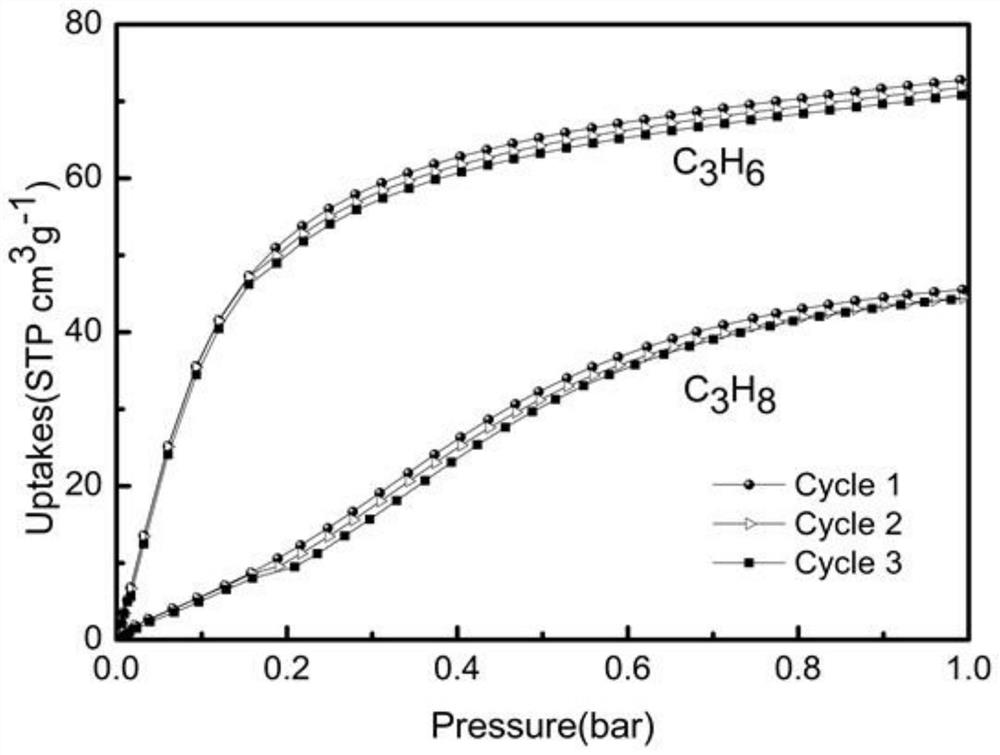

[0046] Dissolve 0.154g nickel hexafluorosilicate in 6mL methanol solution and dissolve 0.056g organic ligand 2-mercaptopyrazine in 12mL methanol solution (with ultrasound for 30min), wherein nickel hexafluorosilicate and 2-mercaptopyrazine The molar ratio of pyrazine is 1:1. After mixing the two solutions, add them into 25mL polytetrafluoroethylene liner, put them into the reaction kettle, heat up 75°C at 10°C / min, react at 75°C for 72h, and finish After cooling down to room temperature, turn off the instrument and take out the sample. The solid yellow powder was obtained by suction filtration through a Buchner funnel, which was a microporous organic-inorganic hybrid porous material. Gas adsorption isotherms were measured by a Micromeritics ASAP 2020 Surface Area Analyzer. To remove all guest solvent from the backbone, fresh powder samples were first solvent-exchanged with anhydrous methanol multiple times over two days. The solvent-exchanged samples were evacuated at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com