Lithium orthosilicate composite material and preparation method and application thereof

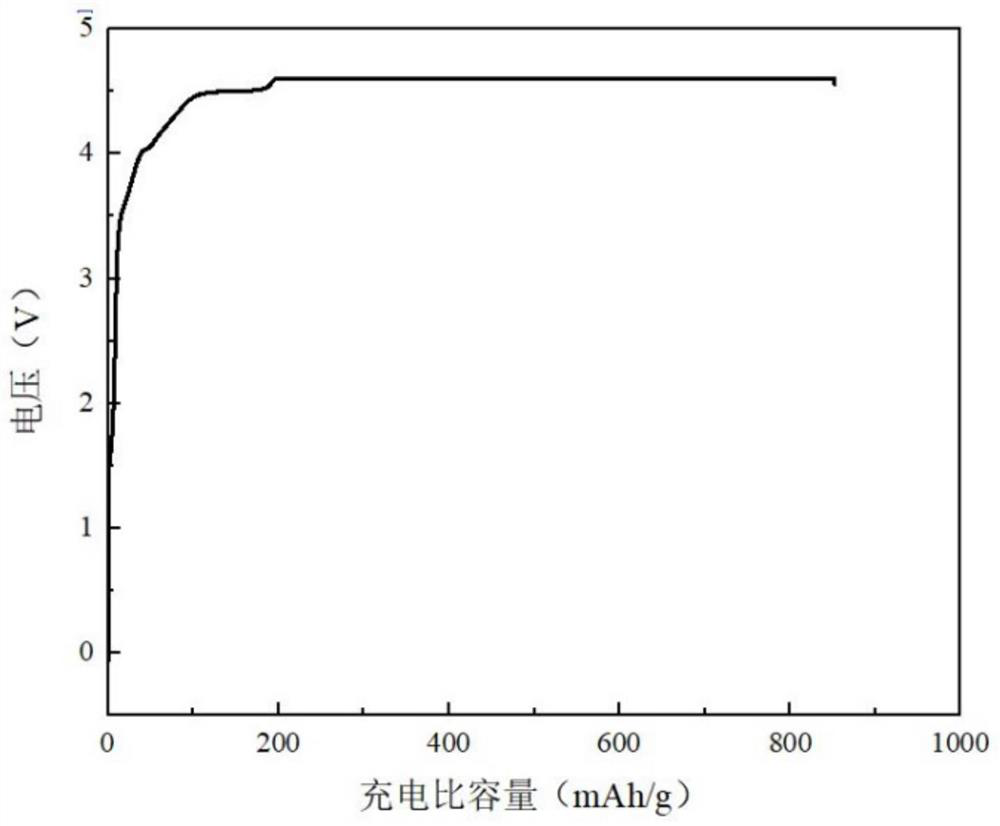

A technology of lithium orthosilicate and composite materials, applied in the field of energy storage, can solve the problems of low charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Specifically, the preparation method of lithium orthosilicate composite material comprises the following steps:

[0051] S1. Obtain lithium source, silicon source, doped metal source and organic carbon source, and mix lithium source, silicon source, organic carbon source and doped metal source to prepare a precursor.

[0052] Wherein, the molar ratio of the metal element in the doped metal source and Si in the silicon source is y:(1-y), 04 Si 1-y x y o 4 , 0<y≤0.2, X represents a metal element. At the same time, because a certain amount of Li or Si may be lost during the sintering process, the molar ratio of Li in the lithium source to Si in the silicon source is (3.2-4.4): 1, specifically for example, Li in the lithium source and Si in the silicon source The Si molar ratio is 3.2:1, 3.5:1, 3.8:1, 3.9:1, 4:1, 4.1:1 or 4.4:1, etc.

[0053] Wherein, the organic carbon source is solid, and the organic carbon source here refers to an organic matter composed of carbon sk...

Embodiment 1

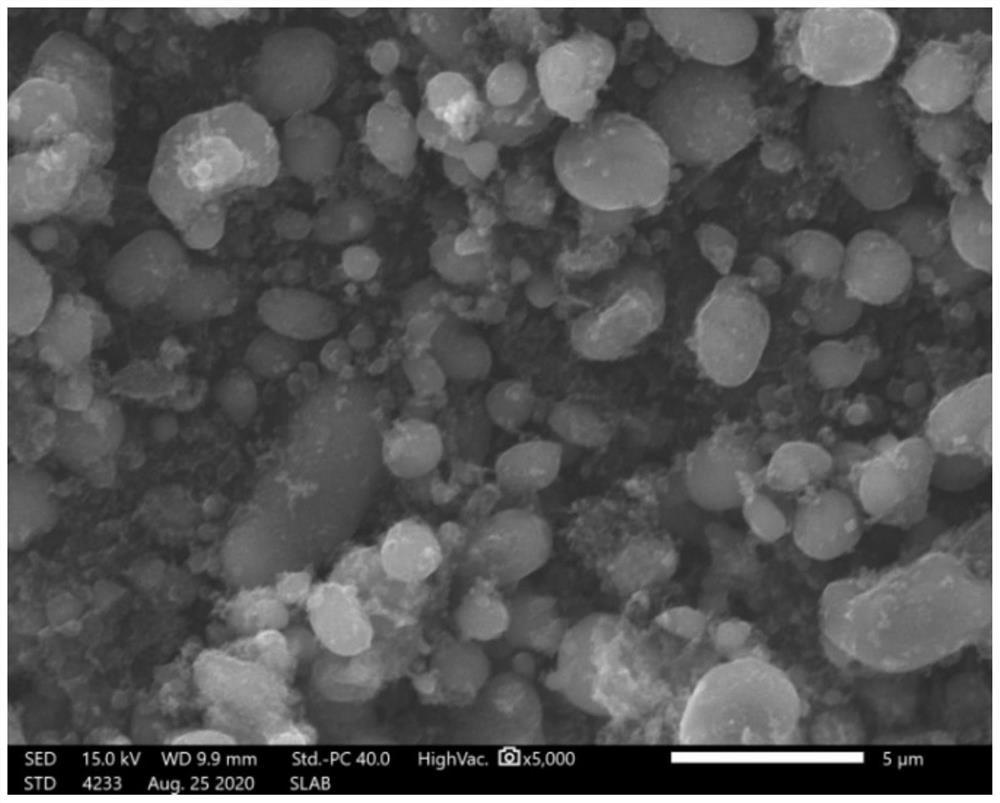

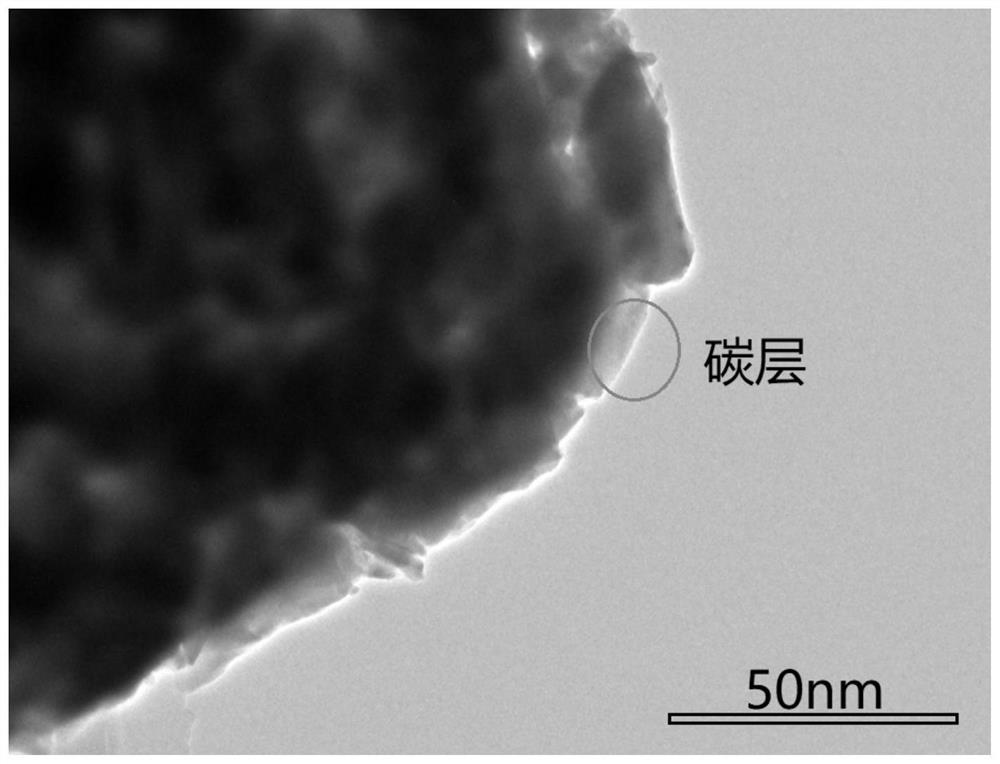

[0090]1. Take 800ml of absolute ethanol as a solvent, add 125g of nano silicon dioxide and 307.45g of lithium carbonate to it, stir and mix evenly, put it into a ball mill jar, add 1.25g of titanium dioxide and then add 83.3g of glucose, then carry out stirring ball milling, After ball milling, put the slurry in a blast drying oven and bake at 80°C for 10 hours. After drying, crush and sieve to obtain the precursor. Put the precursor into a tube furnace for sintering, protected by argon, and the sintering condition is 800°C. After sintering for 6 hours, after the tube furnace was naturally cooled, the sample was taken out, crushed and sieved to obtain a titanium-doped carbon-coated lithium orthosilicate material, which was denoted as a1.

[0091] 2. Take 800ml of absolute ethanol as a solvent, add 100g of nano silicon dioxide and 276.96g of lithium carbonate to it, stir and mix evenly, put it into a ball mill jar, add 1.25g of titanium dioxide and then add 83.3g of glucose, the...

Embodiment 2

[0098] 1. Take 600ml of deionized water as a solvent, add 100g of nano silicon dioxide and 248.42g of lithium carbonate into it, mix well and put it into a ball mill jar, add 4.3g of titanium dioxide at the same time, then add 26.7g of polyvinylpyrrolidone, and then stir Ball milling, after ball milling, put the slurry into a blast drying oven and bake at 80°C for 10 hours, after drying, crush and sieve to obtain the precursor of lithium orthosilicate, put the precursor into a tube furnace for sintering, and argon Under gas protection, the sintering condition was 700°C for 4 hours. After the tube furnace cooled naturally, the samples were taken out, crushed and sieved to obtain a titanium-doped carbon-coated lithium orthosilicate material, denoted as b1.

[0099] 2. Take 600ml of deionized water as a solvent, add 100g of nano silicon dioxide and 248.42g of lithium carbonate into it, mix well and put it into a ball mill jar, add 4.3g of niobium oxide, then add 26.7g of polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com