Composite sewage treatment agent and preparation method and application thereof

A technology of sewage treatment agent and composite microorganism, which is applied in the field of composite sewage treatment agent and its preparation, can solve the problems of high power consumption, water consumption, poor effect, etc., and achieve good photocatalytic sterilization and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 composite sewage treatment agent

[0045] The preparation method comprises the following steps:

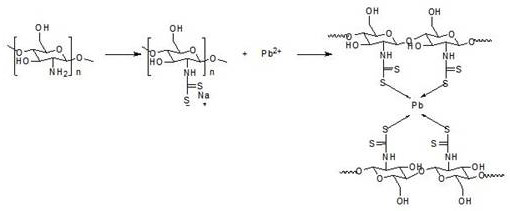

[0046] S1. Preparation of chitosan dithiocarbamate: Dissolve 100g chitosan in 200mL 1wt% acetic acid solution, add 5g NaOH solid, stir well, control the temperature not higher than 5°C, add 75g CS 2 , control the reaction temperature not higher than 40°C, after the dropwise addition, raise the temperature to 45°C and stir for 2h, stop the reaction, add an equal volume of ethanol, filter, and freeze-dry to obtain chitosan dithiocarbamate;

[0047] The obtained dithiocarbamic acid chitosan is carried out infrared detection, in its infrared spectrogram, 3420-3437cm -1 The broad peak at 2875cm is a multiple absorption peak formed by the overlapping of chitosan O—H stretching vibration and N—H stretching vibration absorption. -1 is methylene—CH 2 - stretching vibration peak at 1185cm -1 It is the stretching vibration peak of C=S in NH-C=S, at 1157 and 1072cm -1...

Embodiment 2

[0056] Embodiment 2 composite sewage treatment agent

[0057] The preparation method comprises the following steps:

[0058] S1. Preparation of chitosan dithiocarbamate: Dissolve 100g chitosan in 200mL 3wt% acetic acid solution, add 10g KOH solid, stir evenly, control the temperature not higher than 5°C, add 92g CS dropwise 2 , control the reaction temperature not to be higher than 40°C, after the dropwise addition, raise the temperature to 65°C and stir for 4h, stop the reaction, add an equal volume of ethanol, filter, and freeze-dry to obtain chitosan dithiocarbamate;

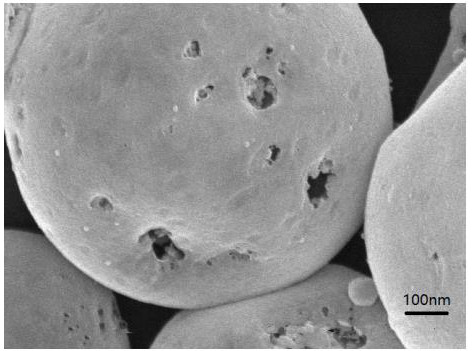

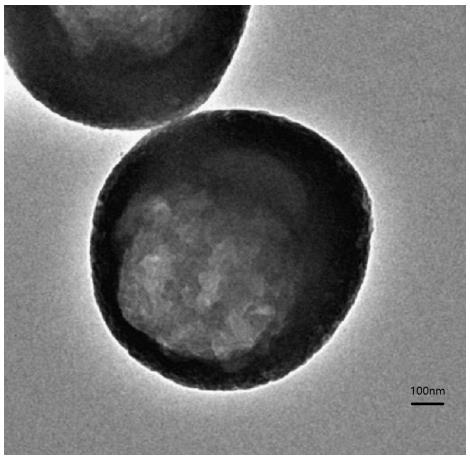

[0059] S2. Preparation of magnetic thick-walled porous titanium dioxide hollow spheres: 100g of tetrapentyl titanate and 5g of titanate coupling agent TMC-27 were dissolved in 200mL of dichloromethane to obtain an oil phase; 30g of ferrous chloride, Dissolve 25g of cobalt chloride, 20g of sodium dodecylsulfonate and 10g of porogen in 70mL of water to obtain a water phase; add the water phase dropwise to the ...

Embodiment 3

[0067] Embodiment 3 composite sewage treatment agent

[0068] The preparation method comprises the following steps:

[0069] S1. Preparation of chitosan dithiocarbamate: Dissolve 100g of chitosan in 200mL of 2wt% acetic acid solution, add 7g of NaOH solid, stir well, control the temperature not higher than 5°C, add 84g of CS 2 , control the reaction temperature not to be higher than 40°C, after the dropwise addition, raise the temperature to 55°C and stir for 3h, stop the reaction, add an equal volume of ethanol, filter, and freeze-dry to obtain chitosan dithiocarbamate;

[0070] S2. Preparation of magnetic thick-walled porous titanium dioxide hollow spheres: 100g of tetraisopropyl titanate and 3g of titanate coupling agent TMC-3 were dissolved in 200mL of dichloromethane to obtain an oil phase; 22g of ferrous chloride , 20g cobalt chloride, 18g sodium stearate and 7g porogen were dissolved in 70mL water to obtain the water phase; the water phase was added dropwise to the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com