Compound microorganism bacteria solution and application thereof in hydroponic culture Cucumis sativus L.

A technology of compounding microbial bacteria and microbial bacteria liquid, applied in the directions of microorganism-based methods, microorganisms, applications, etc., can solve problems such as increased cost, premature senescence of plants, environmental pollution, etc., to improve yield and quality, improve absorption capacity, alleviate The effect of autotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The hydroponic cucumber nutrient solution additive of the present application is a kind of compound microbial bacterial liquid, provided by the microbial fertilizer research group of Gansu Agricultural University College of Grasslands, the compound microbial bacterial liquid is composed of nitrogen-fixing bacteria (autogenous nitrogen-fixing bacteria), phosphorus-dissolving bacteria; secreting plant Composition of four active microorganisms: hormonal bacteria and biocontrol bacteria, specifically: a mixture of bacterial agents obtained from the expansion of the following four strains: Bacillus mycoides Gnyt1 strain, the preservation number is CCTCC M 2017177; Bacillus subtilis The Bacillus subtilis FX2 strain has a preservation number of CCTCC M 2017178; the Bacillus subtilis PBRS2 strain has a preservation number of CCTCC M 2017179; and the Bacillus subtilis LSH11 strain has a preservation number of CCTCC M 2017180.

[0040] Among them, the Bacillus mycoides Gnyt1 strai...

Embodiment 2

[0048] The using method of the hydroponic cucumber culture fluid additive of the present application is:

[0049] A: The composite microbial bacterial liquid prepared in Example 1.

[0050] B: Full amount of nutrient solution, using Japanese garden formula, the ingredients are as follows:

[0051] Major elements: calcium nitrate tetrahydrate 945 (mg / L); potassium nitrate 809 (mg / L);

[0052] Ammonium dihydrogen phosphate 153(mg / L); Magnesium sulfate heptahydrate 493(mg / L);

[0053] Trace elements: disodium edetate 27.8 (mg / L); ferrous sulfate heptahydrate 37.2 (mg / L); boric acid 2.86 (mg / L); manganese sulfate tetrahydrate 2.13 (mg / L);

[0054] Zinc sulfate heptahydrate 0.22 (mg / L); Copper sulfate pentahydrate 0.08 (mg / L);

[0055] Ammonium molybdate tetrahydrate 0.02 (mg / L).

[0056] 2. How to use:

[0057] (1) When cultivating cucumber seedlings, the nutrient solution adopts 1 / 2 amount of Japanese garden formula, and no compound microbial bacterial solution is added;

...

Embodiment 3

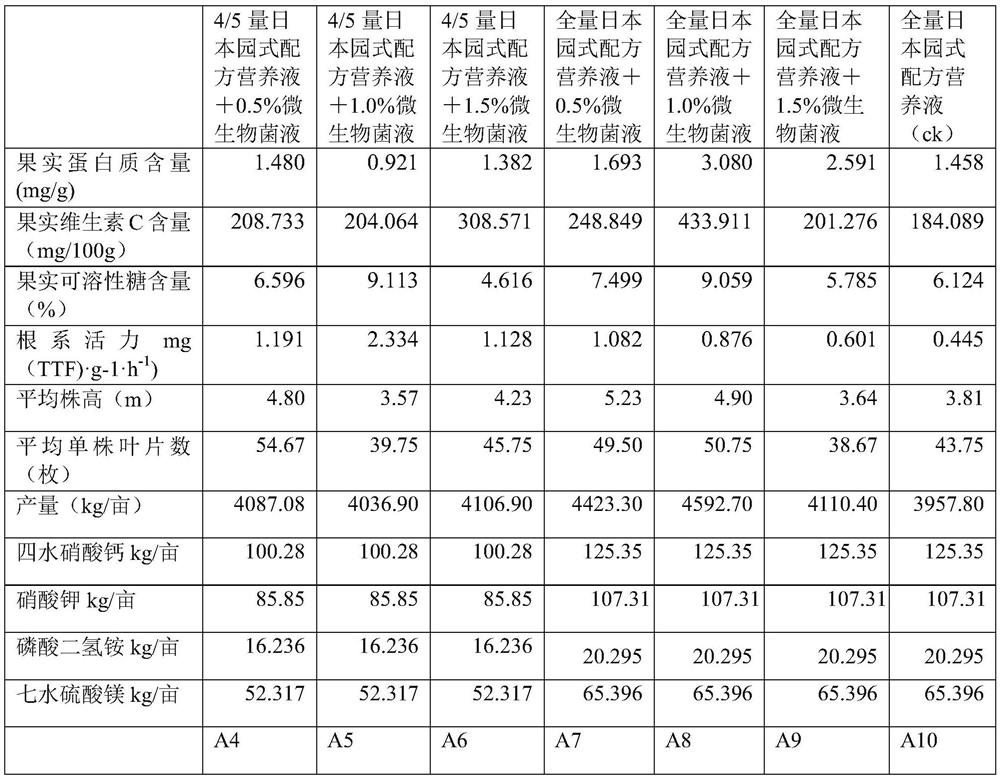

[0065] A hydroponic cucumber culture solution provided by the present invention contains a variety of beneficial microorganisms. By optimizing the concentration and adding time, it can provide a good growth environment for hydroponic cucumbers, improve the yield and quality of cucumbers, and reduce the cost of hydroponic vegetables. The operation method is simple, the cost is low, and the result is reliable. The specific experiment is as follows:

[0066] When the cucumber enters the spreading period, different nutrient solution formulas are used for comparative experiments, and the experiment is divided into seven groups: the first group: the control group: the full amount of Japanese garden formula nutrient solution, without compound microbial bacterial solution; the second group: Full amount of Japanese garden formula nutrient solution + 1.5% microbial bacterial solution;

[0067] The third group: full amount of Japanese garden formula nutrient solution + 1.0% microbial ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com