Preparation method and preparation device of high-purity metal film and semiconductor chip

A metal film, high-purity technology, applied in semiconductor devices, metal material coating process, coating and other directions, can solve the problems of cumbersome preparation process of high-purity refractory metal film, achieve low cost, low purity requirements, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

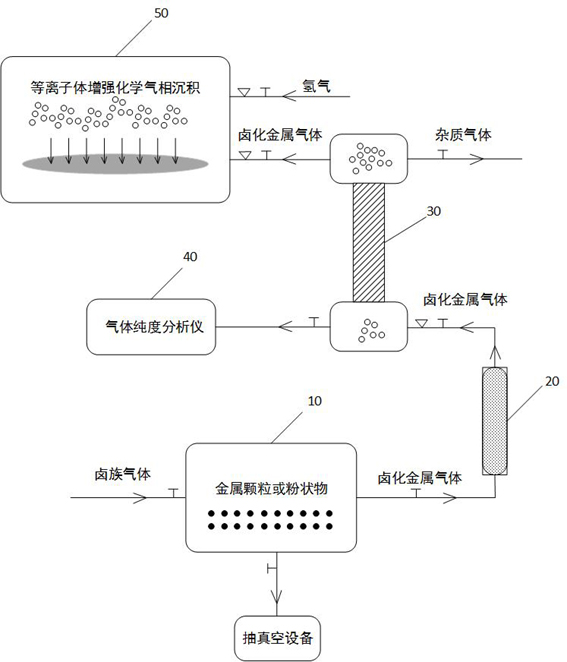

Image

Examples

Embodiment 1

[0073] First, put refractory metal tungsten particles or powder in a vacuum chamber, the diameter of the particles is less than 6mm, vacuumize for 1.6 hours, and the vacuum degree reaches 10 -6 mbar and above;

[0074] Introduce high-purity fluorine gas and tungsten metal for full contact reaction at room temperature, and the reaction time is controlled within 2 hours to obtain tungsten hexafluoride gas;

[0075] The tungsten hexafluoride metal gas obtained after the reaction is conveyed from bottom to top through the adsorption filter device. The filter device is 800mm in height and 60mm in diameter. Activated alumina with a diameter of 3mm is used as the adsorbent for preliminary purification, and the flow rate is controlled at 50sccm ;

[0076] The preliminary purified gas is sent to the rectification tower. The height of the rectification tower is 1500mm and the diameter is 90mm. The temperature at the bottom of the tower is controlled between 17°C and 30°C. The purifica...

Embodiment 2

[0084] First, put refractory metal tantalum particles or powder in a vacuum chamber, the diameter of the particles is less than 5mm, vacuumize for 1 hour, and the vacuum degree reaches 10 -6 mbar and above;

[0085] Introduce high-purity fluorine gas and tantalum metal for full contact reaction at room temperature, and the reaction time is controlled at 1.5 hours to obtain tantalum pentafluoride gas;

[0086] The tantalum pentafluoride gas obtained after the reaction is conveyed from bottom to top through the adsorption filter device. The filter device is 700mm in height and 50mm in diameter, and a mixture of NaF and KF with a diameter of 3mm is used (the mass ratio of NaF and KF is 1: 1) As an adsorbent for preliminary purification, the flow rate is controlled at 50 sccm;

[0087]The preliminary purified gas is sent to the rectification tower. The height of the rectification tower is 800mm and the diameter is 40mm. The temperature at the bottom of the tower is controlled bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com