Compound enzyme preparation and ochrobactrum assisted kitchen waste new high-temperature composting technology

A pale bacillus, high-temperature composting technology, applied in the field of microbial technology and environmental engineering, can solve the problems of difficulty in reaching higher and stable composting temperature, inability to greatly improve fermentation efficiency, and limitations, and achieve reduced scale, broad substrate spectrum, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Screening and Identification of Paleobacterium pallidum CGMCC No.19230

[0043] (1) Sample collection

[0044] Microbial samples were collected from high-temperature composting test samples of kitchen waste in the canteen of Yuhang Senior Middle School in Yuhang District, Zhejiang Province.

[0045] (2) Isolation, purification and preservation of strain CGMCC No.19230

[0046] Self-designed and prepared "yeast sucrose YZ medium": yeast extract 5g / L, sucrose 10g / L, peptone 10g / L, sodium chloride 5g / L, pH=7.0. Add agar 20g / L when making solid medium.

[0047] Put 1 g of the sample into an Erlenmeyer flask filled with 100 mL of sterile distilled water and some sterile glass beads, and shake it at 120 rpm (rotation per minute) for 10 minutes to obtain a suspension. Take 1mL of the suspension, dilute and spread it on the sterile YZ solid medium, place it in a constant temperature incubator at 60°C for 2-3 days, pick a single colony after obvious bacteria appear ...

Embodiment 2

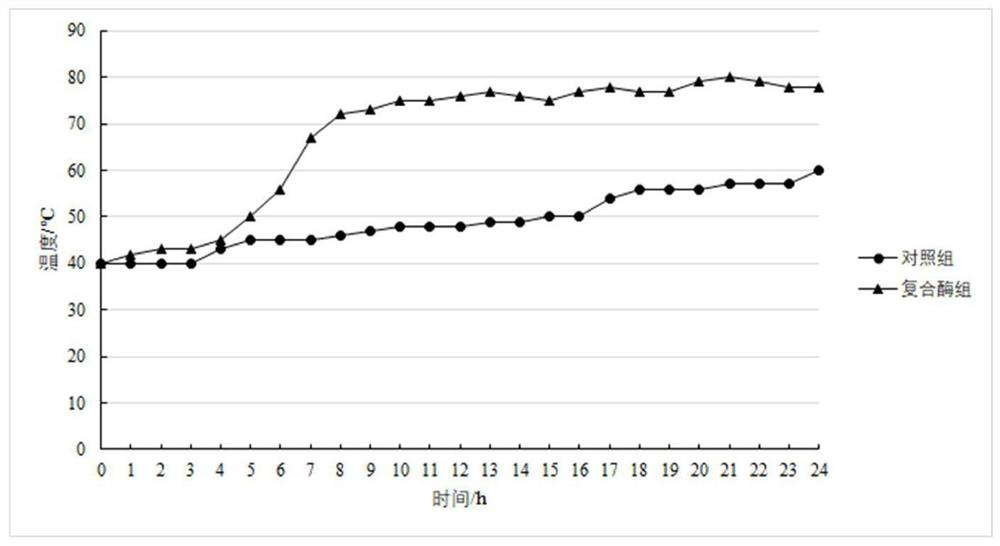

[0057] Embodiment 2 compound enzyme is to the rapid heating effect of pale bacillus

[0058] Laccase (EC 1.10.3.2) powder: commercially available food-grade laccase from Jinan Dongxuan Bioengineering Co., Ltd.

[0059] Lipase (EC 3.1.1.3) powder: commercially available Longda food-grade lipase (Aspergillus oryzae, 100,000 units of enzyme activity).

[0060] Phospholipase A (EC 3.1.1.4) powder: commercially available Sigma-Aldrich phospholipase A2 P6534 enzyme 9001-84-7.

[0061] Phospholipase B (EC 3.1.1.5) powder: SUNSON / Xiasheng brand lysophospholipase (food grade).

[0062] Take 1 ton of kitchen waste, crush it to about 5cm pieces, add 20% dry and crushed straw, stir well, add 2% CGMCC No.19230 bacterial liquid, add 2‰ laccase powder and stir well Adjust pH=9.0, then add 1‰ lipase (EC 3.1.1.3) powder, 0.5‰ phospholipase A (EC 3.1.1.4) powder, 0.5‰ phospholipase B (EC 3.1.1.5) powder, keep for 5 hours After that, stir and ventilate every 30 minutes. A group without lacca...

Embodiment 3

[0063] Embodiment 3: the application of compound enzyme preparation and Pallidum in high temperature composting

[0064] 1: Kitchen waste composting

[0065] Take 2 tons of kitchen waste, and the solid-liquid mixture is cut and stirred to make the solid into pieces with a diameter of about 5cm. Put the solid and liquid garbage into the fermentation device with stirring function, and add 600Kg of dry rice husk, and mix well and evenly. Put 20Kg of CGMCC No.19230, add 3Kg of laccase powder, and stir once per minute for 60 minutes. Add 40Kg of quicklime to the compost heap several times, stir evenly so that the pH reaches 9.5, add 5Kg of esterase mixture, and stir evenly. Then the compost heap is stirred and ventilated every 30 minutes, and after maintaining for 6 hours, the temperature rises to 70°C. Put in heat-resistant bacillus for high-temperature composting, keep the temperature between 70-100°C, complete composting and fermentation after 2 days, and the weight of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com