Efficient and environment-friendly recovery method for precious metal palladium in retired solid oxide fuel cell

A solid oxide, fuel cell technology, applied in the disposal/recycling of fuel cells, battery recycling, recycling technology, etc., can solve the problems of non-conformity, waste of resources, difficult to apply precious metal recycling fields, etc., and achieve mild recycling conditions, Extended recovery, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 4) [Hbet][Tf2N] ionic liquid is prepared by the following steps:

[0032] a. The betaine hydrochloride solution and the lithium bistrifluoromethanesulfonimide aqueous solution were mixed and stirred at room temperature for 2 hours;

[0033] b. Separate the ionic liquid phase and wash it several times with distilled water until no precipitation is detected in the silver nitrate test; after evaporation and drying, make [Hbet][Tf2N] ionic liquid; wherein, the concentration of betaine hydrochloride solution is 4mol / L, lithium bistrifluoromethanesulfonylimide aqueous solution is 2mol / L;

[0034] 5) placing the filter residue obtained in step 3) in the prepared [Hbet][Tf2N] ionic liquid, and leaching at a temperature of 85-95° C. to obtain a leaching solution;

[0035] 6) Use the leaching solution obtained in step 5) as the electrolyte, and simultaneously use the glassy carbon electrode as the working electrode, the glassy carbon electrode as the counter electrode, and the ...

Embodiment 1

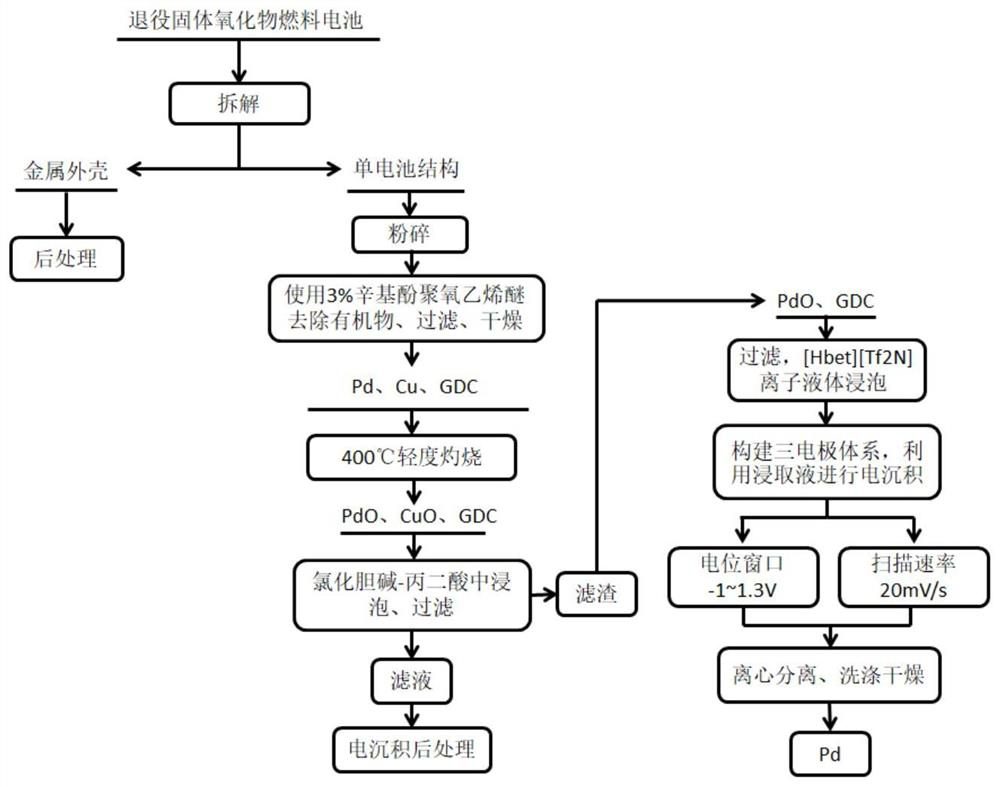

[0039] Such as figure 1 The efficient and environmentally friendly recovery method of precious metal palladium in the decommissioned solid oxide fuel cell shown comprises the following steps:

[0040] Ⅰ. Disassemble the decommissioned solid oxide fuel cell with Pd as the cathode, Cu-GDC as the anode and GDC as the electrolyte to obtain a single cell structure, put it in a pulverizer for 5-10 minutes, and then disassemble the pulverized The powder is soaked in octylphenol polyoxyethylene (9-10) ether (TX-10) with a mass fraction of 3% for more than 24 hours, and stirred irregularly. Heat to boil for 20 minutes, remove the organic layer while hot. Filter and wash, and put the filter residue into an oven for drying.

[0041] Ⅱ. Put the dried powder in a clean and dry porcelain crucible, and lightly burn it in a muffle furnace for 1 hour at a temperature of 400°C. After washing and filtering, the powder was placed in a deep eutectic solvent made of choline chloride-malonic acid...

Embodiment 2

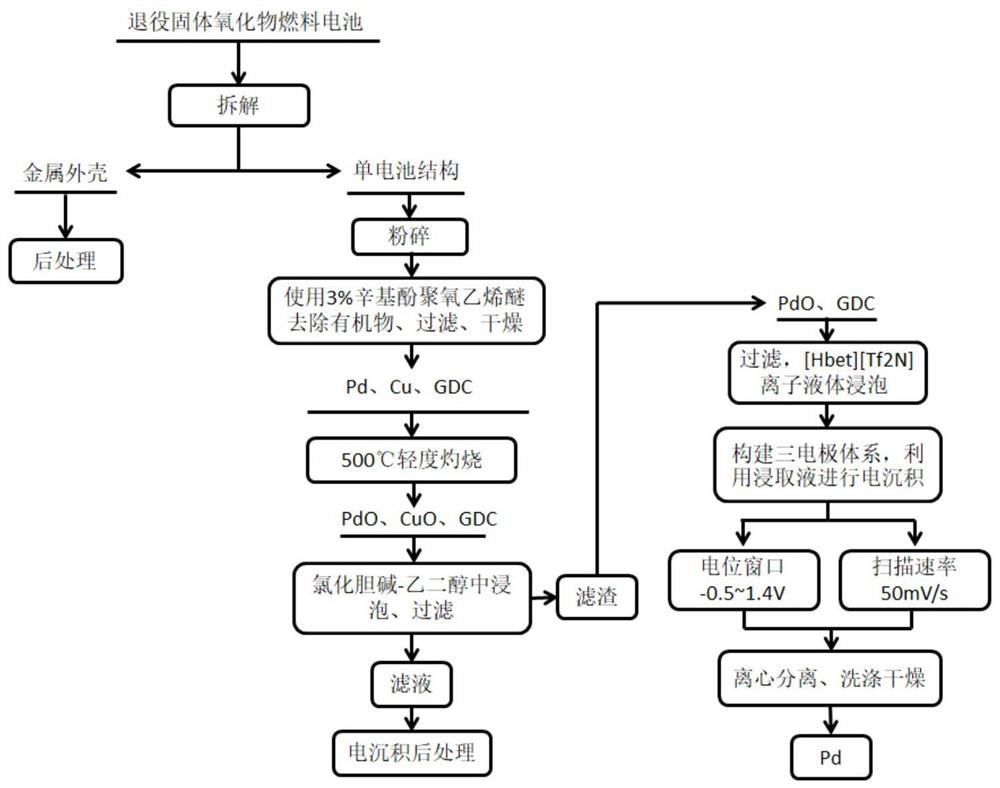

[0046] Such as figure 2The efficient, environment-friendly recovery method of precious metal palladium in the decommissioned solid oxide fuel cell shown, its step is similar to the step of embodiment 1, and its difference is:

[0047] 1. The time of heating and boiling in step Ⅰ is 30 minutes.

[0048] 2. The temperature of the slight burning in the muffle furnace in step II is 500° C., and the deep eutectic solvent used is choline chloride-ethylene glycol.

[0049] 3. In step 4 and Ⅳ, the potential window is set to -0.5~1.4V, and the scan rate is 50mV / L.

[0050] 4. The rotating speed of the centrifuge in the step Ⅴ is 5000r / min.

[0051] The idea and method for separating and recovering noble metal Pd in decommissioned solid oxide fuel cells proposed by the present invention have a simple process and are easy to realize. Based on the leaching of metal oxides by the green functional ionic liquid [Hbet][Tf2N], the electrodeposition of Pd is carried out by making full use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com