Preparation method of Chinese wolfberry enzyme

A wolfberry enzyme and technology of wolfberry, applied in the field of enzymes, can solve the problems of unstable taste and flavor of enzymes, risks of enzyme safety, and high risk of fermentation pollution, etc., to achieve the regulation of gastrointestinal health, excellent taste and flavor, chemical The effect of speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] (1) Preparation of standard solution: Accurately weigh 0.1 g of glucose, dissolve it in distilled water and adjust the volume to 100 mL, and prepare a 1 g / L standard solution.

[0036] (2) Preparation of standard curve: Accurately draw 1mL of glucose standard solutions of different concentrations and place them in test tubes. The blank is 1mL of distilled water, add 2mL of DNS solution, boil in a boiling water bath for 5min, add 15ml of distilled water to dilute, and measure at 540nm Absorbance, the abscissa is the concentration of glucose, the ordinate is the absorbance value, and the regression equation is obtained.

[0037] (3) Determination of total sugar concentration in the sample: take out the enzyme sample solution, centrifuge to get 0.5mL supernatant, add 2ml of 6mol / L hydrochloric acid solution, boil in boiling water for 30min, add 2 drops of phenolphthalein solution dropwise after cooling, then add 6mol / L L sodium hydroxide solution until the original solutio...

Embodiment 1

[0054] After washing the dried fruit of Ningxia wolfberry, put it in an oven, dry it at 60°C to constant weight, weigh 10wt% dried fruit of wolfberry, 1wt% sucrose, 0.01wt% ascorbic acid, 1wt% tea, 3wt% Mix the powder (Zuziziren, Albizia Julibrissin, Poria cocos, Baiziren, Polygala in a mass ratio of 1:1:0.5:0.1:0.1), the rest is distilled water to make a fermentation medium, sterilize at 121°C for 15 minutes, and then add fermentation quality System 10wt% kombucha bacteria liquid, fermentation period is 10 days.

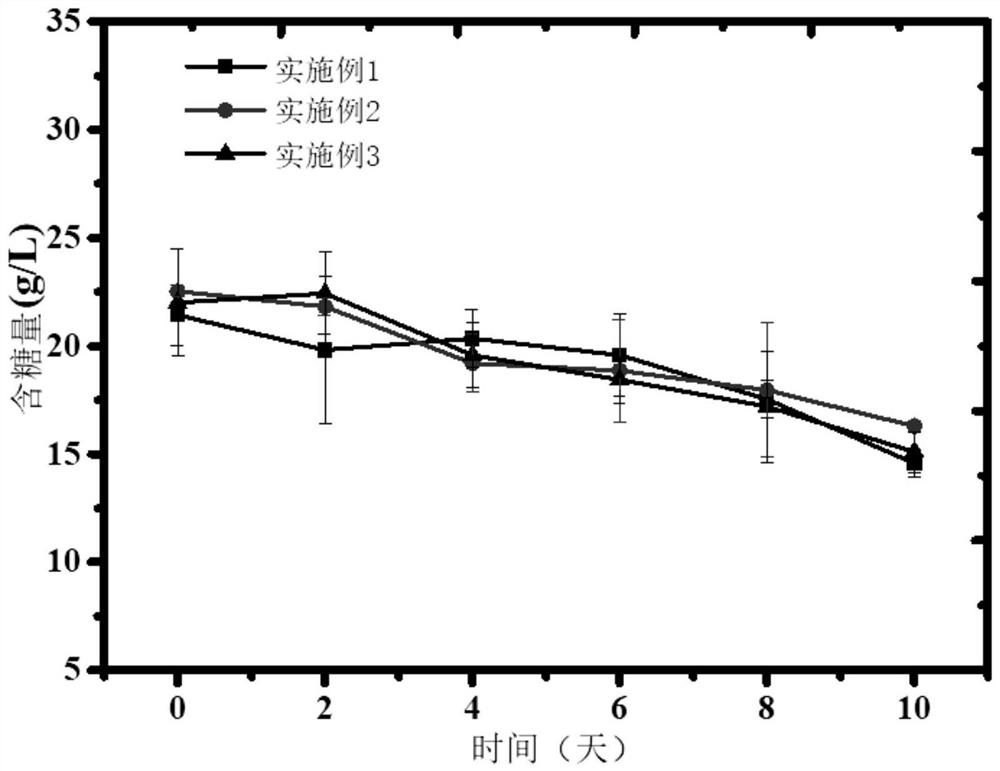

[0055] Depend on figure 1 It can be seen that the total sugar concentration of the wolfberry ferment obtained above decreases with the prolongation of the fermentation time, and the total sugar concentration on the 10th day of fermentation is 14.6g / L, which is 31.9% lower than the initial.

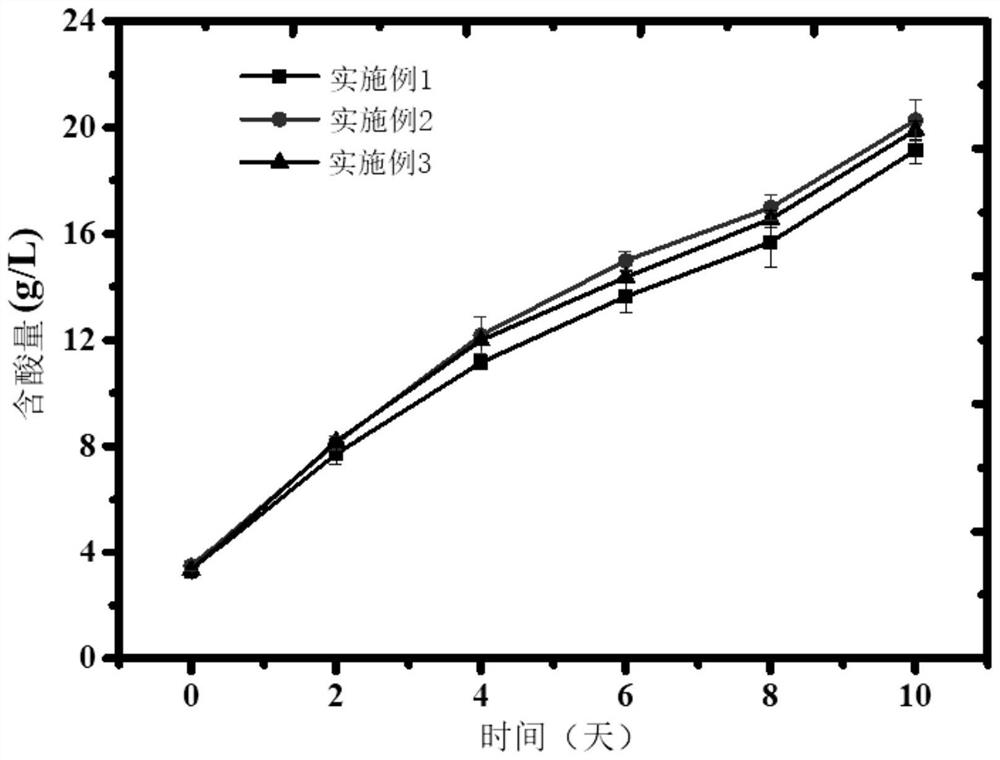

[0056] Depend on figure 2 It can be seen that the total acid concentration of the wolfberry ferment obtained above gradually increases with the prolongation of the fermentati...

Embodiment 2

[0061] Wash the dried fruit of Ningxia wolfberry, put it in an oven, and dry it at 60°C to constant weight. Take the dried fruit of wolfberry with a mass system of 10wt%, add an ethanol solution with a concentration of 80% according to the ratio of solid to liquid ratio of 1:9, and heat it at 80°C. After reflux in the water bath for 2.5h, after the ethanol was reclaimed by the rotary evaporator for the filtrate, 1wt% sucrose, 0.01wt% ascorbic acid, 1wt% tea of the quality of the fermentation system were added, and 3wt mixed powder (Zuziziren, Albizia Julibrissin, Poria cocos , Baiziren, Polygala according to the mass ratio 1:1:0.5:0.1:0.1), the remainder is distilled water to make the fermentation medium, after sterilizing at 121°C for 15min, then add 10wt% kombucha bacterium liquid of the fermentation quality system, and ferment The cycle is 10 days.

[0062] Depend on figure 1 It can be seen that the total sugar concentration of the wolfberry ferment obtained above decrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com