Preparation, product and application of sandwich type degradable stent for alveolar bone repair

A sandwich type, alveolar bone technology, applied in coating, medical science, prosthesis, etc., can solve the problems of easy collapse of shape, unstable effect of alveolar bone and alveolar ridge height, non-degradable metal fixation, etc. Achieve the effect of improving compatibility and overcoming extramucosal exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

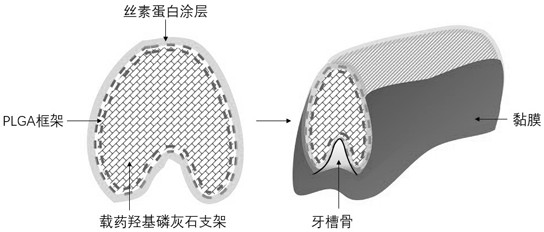

[0026] A "sandwich" degradable scaffold for alveolar bone repair, prepared self-curing hydroxyapatite and PLGA double-layer scaffold by double-nozzle 3D printing; after that, the polyester surface was aminated, and the EDC / NHS couple was used to Combined reaction chemical immobilization of silk fibroin coating loaded with endothelial growth-promoting drugs, prepared according to the following steps:

[0027] (1) Preparation of α-TCP:

[0028] Dibasic calcium phosphate powder and calcium carbonate powder were weighed at a molar ratio of 2:1, and an appropriate amount of absolute ethanol was used as the medium for wet ball milling at a rotational speed of 400 rpm, ball milling time of 4 h, and a mass ratio of ball milling beads to powder of 2:1. The raw material mixture was removed by rotary evaporation to remove ethanol, and dried in an oven at 60°C for 24 hours; the dried powder was placed in a muffle furnace, calcined at 1400°C for 2 hours, taken out, and rapidly cooled in a ...

Embodiment 2

[0035] A "sandwich type" degradable scaffold for alveolar bone repair. Prepare a 3D printed scaffold according to steps (1) and (2) of Example 1, and soak the printed scaffold in 50% (v / v) ethanol aqueous solution Ultrasound for 2 hours, then rinse with a large amount of water, place the cleaned stent in a mixed solution of 1,6-hexanediamine and isopropanol at 45°C for 5 minutes, wash with deionized water for 12 hours, and dry in vacuum for 24 hours. A surface-aminated scaffold is obtained. Prepare EDC / NHS / MES cross-linking agent aqueous solution with a concentration of 20mM / 10mM / 10mM, and then prepare a mixed solution of 0.1g / mL silk fibroin and 2μg / mL VEGF; mix the cross-linking solution and the mixed solution at a volume ratio of 1:9 After that, the PLGA-aminated scaffold was soaked in it immediately, and reacted at 37°C for 4h. After the reaction, the surface of the stent is washed with water and freeze-dried to obtain a sandwich-type degradable stent.

Embodiment 3

[0037] A "sandwich" degradable scaffold for alveolar bone repair. Prepare 3D printed scaffolds according to Example 1 (1) and (2), soak the printed scaffolds in 50% (v / v) ethanol aqueous solution and ultrasonically 2 hours, then rinsed with a large amount of water, placed the cleaned stent in a mixed solution of 1,6-hexanediamine and isopropanol at 45°C for 5 minutes, washed with deionized water for 12 hours, and dried in vacuum for 24 hours to obtain Surface aminated scaffolds. Prepare EDC / NHS / MES cross-linking agent aqueous solution with a concentration of 20mM / 10mM / 10mM, and then prepare a mixed solution of 0.1g / mL silk fibroin and 5μg / mL VEGF; mix the cross-linking solution and the mixed solution at a volume ratio of 1:9 After that, the PLGA-aminated scaffold was soaked in it immediately, and reacted at 37°C for 4h. After the reaction, the surface of the stent is washed with water and freeze-dried to obtain a sandwich-type degradable stent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com