Salmon processing method

A processing method, salmon technology, applied in the preservation of meat/fish, the function of food ingredients, the preservation of food ingredients as antimicrobial, etc., can solve the problem of the reduction of fatty acid and phospholipid content, the difficulty of salmon processing, and the decline of consumers' desire to buy and other issues, to achieve the effects of increasing the relative content and phospholipid content, improving brightness and bright red effect, and excellent eating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0051] Experimental example 1: 400g of artificially cultured Atlantic salmon and king salmon were purchased from Zhejiang Ocean Fishery Group Co., Ltd., and the middle part of the fish was taken and cut into small pieces of 2cm*2cm*2cm as samples. Then use the TMS-PRO food physical property analyzer to measure the texture of the two samples, equipped with a P / 36R probe, using the full texture mode, the pre-test speed: 2.0mm / s, the test speed: 2.0mm / s, after the test Speed: 2.0mm / s, strain ratio 70%, compression times 2 times. The two samples were measured three times and the average value was taken. The texture data of the two groups of samples were evaluated from the three aspects of elasticity, chewiness and adhesiveness. The test results are shown in Table 1:

[0052] Table 1 Texture data of king salmon and Atlantic salmon

[0053]

[0054] It can be seen from the test that king salmon is slightly higher than Atlantic salmon in terms of elasticity, chewiness and stickin...

experiment example 2

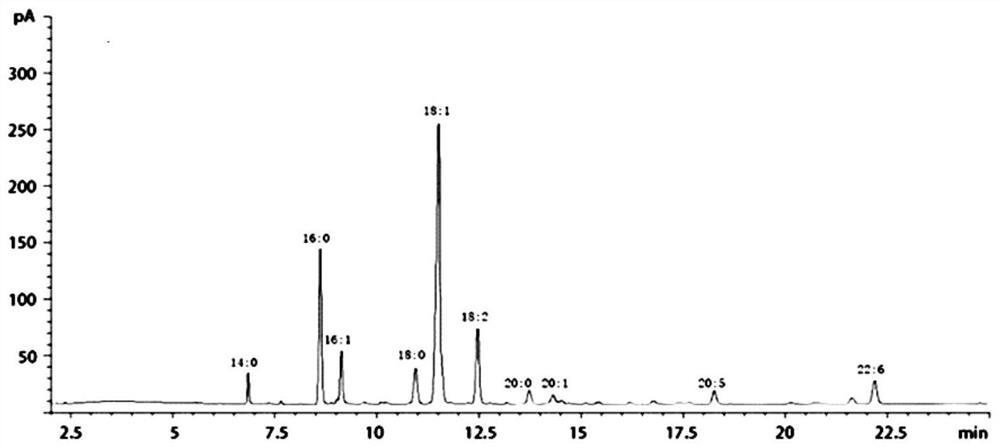

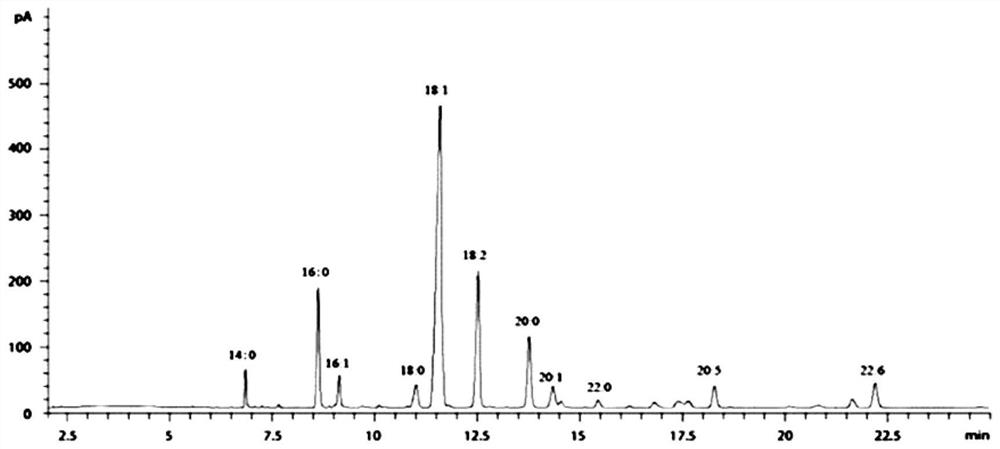

[0055] Experimental example 2: adopt Folch method to carry out lipid extraction to two kinds of salmon samples in embodiment 1, concrete method is to place in the sample of weighing 3g respectively in the 50mL centrifuge tube, then add the dichloromethane-methyl alcohol of 24mL (2: 1, V / V) solution, ultrasonically assisted extraction for 30min, then add 12mL of ultrapure water to it, shake fully and centrifuge at 8000r / min for 15min to separate layers. The lower organic phase was collected, and the upper aqueous phase was repeatedly extracted with 15 mL of dichloromethane in the same manner. The obtained organic phases were mixed, and the organic phases were concentrated using a rotary evaporator at 55° C. to obtain lipids of two salmon samples.

[0056] Adopt the methyl esterification method to carry out methyl esterification to two groups of lipids, concrete method is to take the lipid of 0.1g in conical flask, add 2mL sodium hydroxide-methanol (0.5M) solution, after lipid i...

experiment example 3

[0063] Experimental Example 3: Use the 1100 type high performance liquid chromatograph equipped with vacuum degasser, autosampler, column chamber and quaternary pump to carry out the Atlantic salmon lipid and king salmon lipid prepared in Example 2 Hydrophilic interaction liquid chromatography (HILIC), followed by separation of phospholipids on a Cosmosil HILIC column (4.6*250 mm, 3 μm). Mobile phase A is an aqueous phase containing 20mM ammonium formate and 0.1% formic acid, and mobile phase B is an organic phase of pure acetonitrile, using the following gradient changes: 0min, 5%A; 3min, 5%A; 18min, 30%A; 23min , 50%A; 28min, 50%A; 32min, 5%A. Flow rate: 0.6mL / min, injection volume: 2μL, column temperature: 30°C. Before each injection, the column was cleaned and reconditioned to initial conditions for good reproducibility.

[0064] Using a 4000 QTRAP triple quadrupole mass spectrometer in negative ion mode, equipped with an electrospray ionization source (ESI), the two gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com