Method for improving open-circuit voltage of organic-inorganic hybrid perovskite solar cell

A solar cell, open circuit voltage technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of lack of passivation effect on defects, and achieve the effect of improving photoelectric conversion efficiency, good uniformity and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

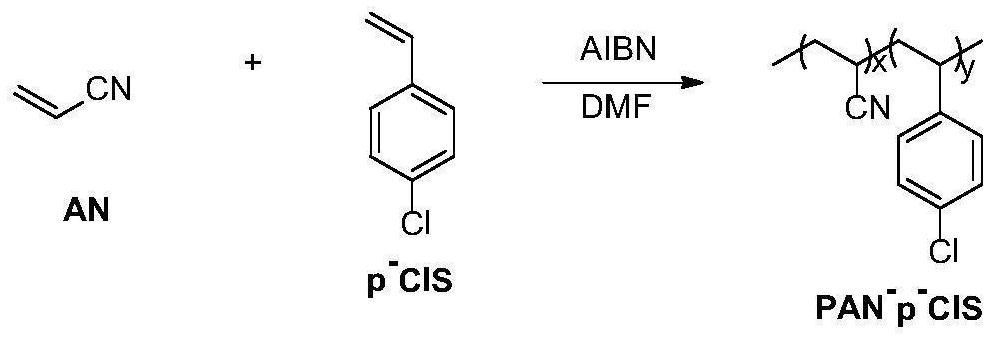

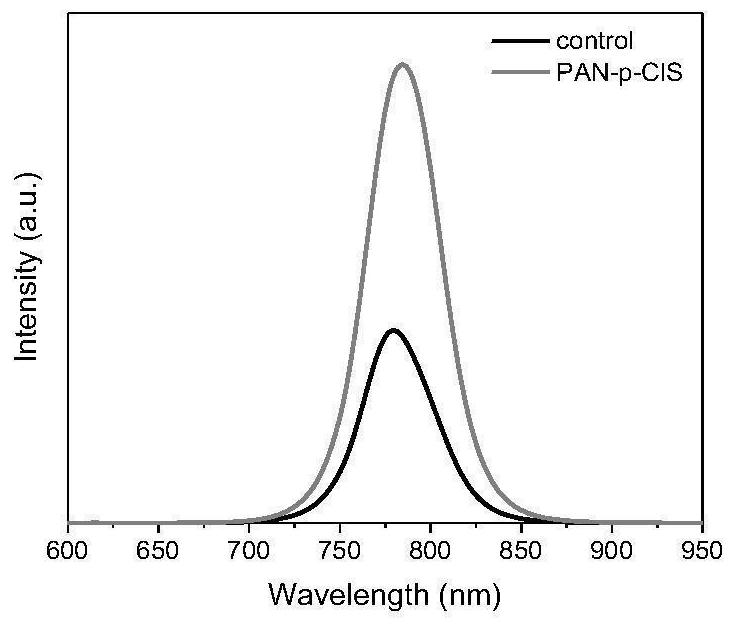

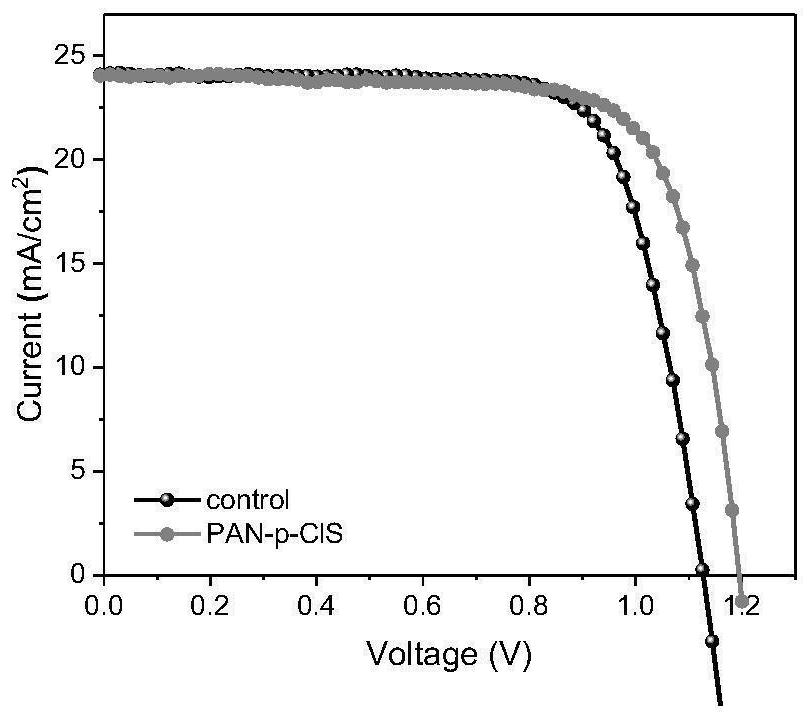

[0049]First synthesis of acrylonitrile and PAN-P-CLS), specific route maps such as chloroprene copolymerfigure 1 Indicated. The specific synthesis steps are as follows:

[0050]Under nitrogen protection, acrylonitrile (AN, 6.3 mmol), chloroprene (Aa, 2.1 mmol), azo diisobutyronitrile (AIBN, 10 mg), DMF (10 ml) were added to the pressure resistant bottle; The pressure bottle is placed in an oil bath, and the reaction is 24 h. After the reaction, the polymerization solution was added dropwise into 50 mL of acetone to give a white acrylonitrile and a PAN-P-P-CLS of the chloroprene copolymer.

[0051]Next, 200 cycles are deposited on the clean FTO glass using atomic layer deposition equipment.2, Add the deposited FTO glass to heat treatment at 500 ° C for 30 min to get a dense TiO2film. Spin coating on a dense film SNO2Precursor solution (SNCL4Aqueous solution), spin coating conditions were 3000 rpm, 30s, and then further 180 ° C heating for 30 min, resulting in a dense TiO2 / SNO2Electronic t...

Embodiment 2

[0056]First, methyl acrylate and acrylamide copolymer (PMA-AA), specific route diagram, such asFigure 4 Indicated. The specific synthesis steps are as follows:

[0057]Under nitrogen protection, methyl acrylate (MA, 4.2 mmol), acrylamide (Aa, 0.42 mmol), azoiso (AIBN, 10 mg), DMF (10 mL) were added to the pressure resistant bottle; The bottle is placed in a 70 ° C oil bath, and the reaction is 24h. After completion of the reaction, the polymerization solution was dripped into 50 ml of diethyl ether to give a copolymer solid (PMA-AA) of methyl acrylate and acrylamide.

[0058]Second, in the FTO substrate, TiO is prepared2 / SNO2The electron transport layer, the method is as above. Configure the percent-titanium mine solution, according to the Moore percentage (1: 0.97: 0.03) will put PBI2: FAI: MABR is dissolved in DMSO: DMF = 4: 1 (volume ratio), in the formulated solution PBI2The total concentration of FAI and MABR is 50% of the solution, and the solution is divided into two parts, then t...

Embodiment 3

[0061]First synthesis of maleimide and allyl chloride copolymer (PMI-ACL), specific road maps such asFigure 9 Indicated. The specific synthesis steps are as follows:

[0062]Under nitrogen protection, maleimide (Mi, 2.1 mmol), allyl chloride (ACl, 2.1 mmol), azo diisobutyronitrile (AIBN, 10 mg), DMF (10 ml) were added to the pressure resistant bottle The pressure-resistant bottle was placed in a 70 ° C oil bath and the reaction was 24 h. After the reaction, the polymerization solution was dripped into 50 ml of chloroform to obtain a maleimide and an allyl chloride copolymer solid (PMI-ACL).

[0063]Second, in the FTO substrate, TiO is prepared2 / SNO2The electron transport layer, the method is as above. Configure the percent-titanium mine solution, according to the Moore percentage (1: 0.9: 0.07: 0.03) will put PBI2: FAI: CSI: MABR dissolved in DMSO: DMF = 4: 1 (volume ratio) solution, PBI in formulated solution2, FAI, CSI and MABR total concentrations of 50%, fully dissolved, spin coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com