Full-pH electrocatalytic hydrogen evolution molybdenum disulfide modified sulfur and molybdenum co-doped graphite-phase carbon nitride heterostructure material, and preparation method thereof

A graphite-phase carbon nitride and molybdenum disulfide technology is applied in electrodes, electrolytic processes, electrolytic components, etc., which can solve the problems of limited industrial use, difficult reaction, and low catalytic activity of catalysts, and achieve excellent electrocatalytic hydrogen evolution activity, high Atom utilization efficiency, effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

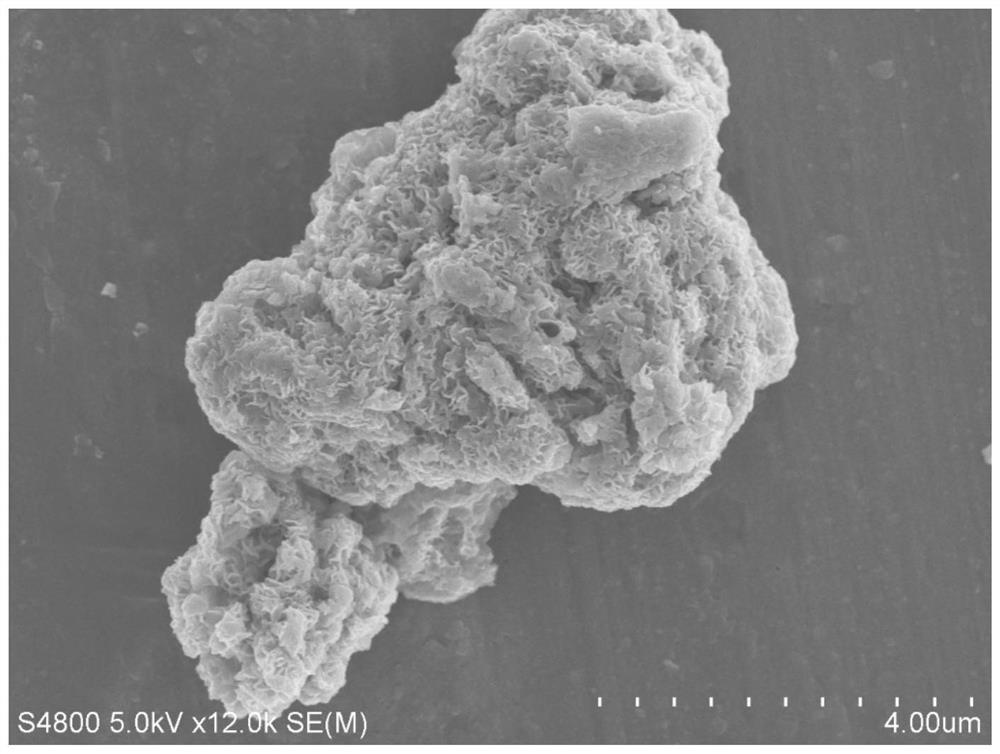

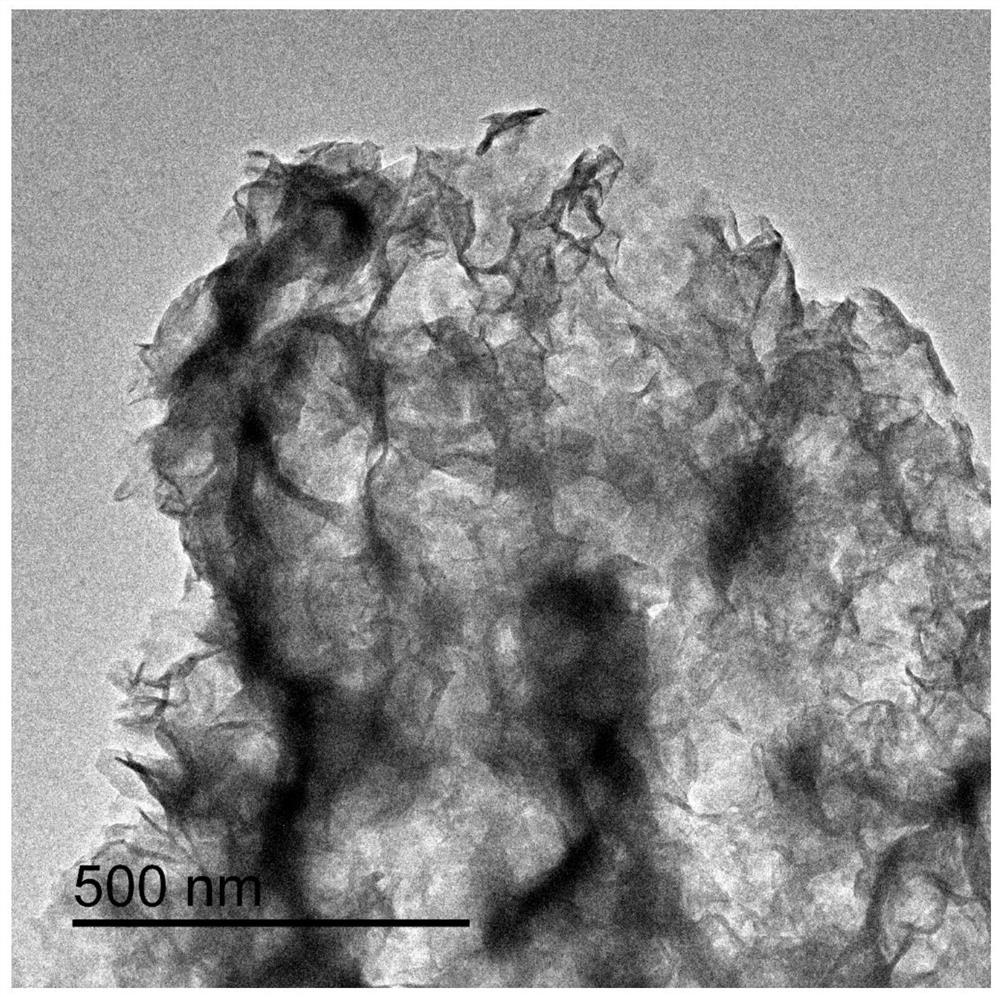

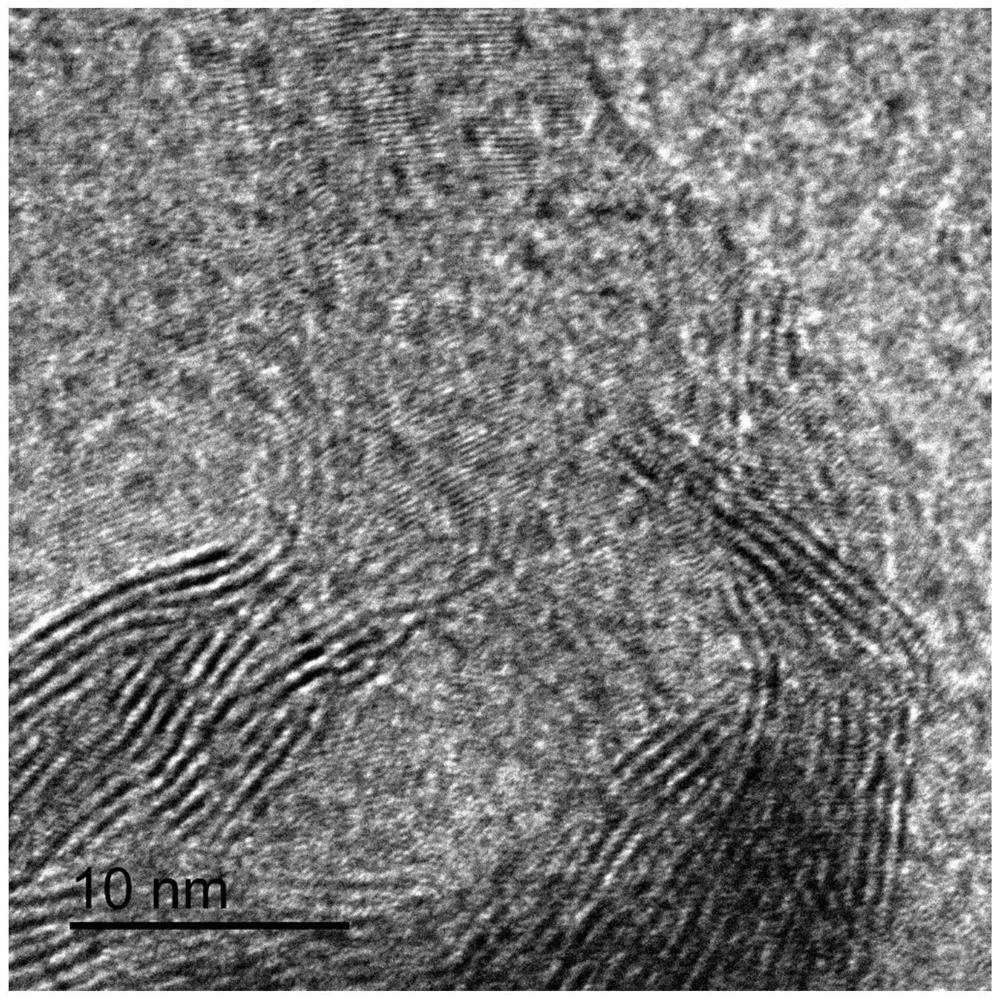

[0036] The invention provides a method for preparing a molybdenum disulfide modified sulfur and molybdenum co-doped graphite phase carbon nitride heterostructure material with full pH electrocatalytic hydrogen evolution, comprising the following steps:

[0037] Step 1: Dissolve 1g of melamine and 0.05g of thiourea in 20mL of deionized water in turn, stir for 1.5h at a water bath temperature of 60°C, take out the mixed solution and put it in an oven, and dry it at 60°C to obtain a reaction precursor mixture a.

[0038] Step 2: Put the precursor mixture A in an alumina porcelain boat, and then place the porcelain boat in an atmosphere furnace for calcination. Before calcination, pass argon for 30 minutes, and then heat up at a rate of 2.3°C / min under argon The temperature was raised from room temperature to 500° C. for 3 h, and after the calcination was completed, the furnace was cooled to room temperature, and the intermediate product B was obtained by grinding.

[0039] Step ...

Embodiment 2

[0044] The invention provides a method for preparing a molybdenum disulfide modified sulfur and molybdenum co-doped graphite phase carbon nitride heterostructure material with full pH electrocatalytic hydrogen evolution, comprising the following steps:

[0045] Step 1: Dissolve 1g of melamine and 0.05g of thiourea in 30mL of deionized water in turn, stir for 1 hour at a water bath temperature of 80°C, take out the mixed solution and put it in an oven, and dry it at 60°C to obtain a reaction precursor mixture A .

[0046] Step 2: Put the precursor mixture A in an alumina porcelain boat, and then place the porcelain boat in an atmosphere furnace for calcination. Before calcination, pass argon for 30 minutes, and then heat up at a rate of 2.3°C / min under argon The temperature was raised from room temperature to 550° C. for 4 h, and after the calcination, the furnace was cooled to room temperature, and the intermediate product B was obtained by grinding.

[0047] Step 3: Add 1 g ...

Embodiment 3

[0052] The invention provides a method for preparing a molybdenum disulfide modified sulfur and molybdenum co-doped graphite phase carbon nitride heterostructure material with full pH electrocatalytic hydrogen evolution, comprising the following steps:

[0053] Step 1: Dissolve 1g of melamine and 0.05g of thiourea in 40mL of deionized water in turn, stir for 1 hour at a water bath temperature of 90°C, take out the mixed solution and put it in an oven, and dry it at 60°C to obtain a reaction precursor mixture A .

[0054] Step 2: Put the precursor mixture A in an alumina porcelain boat, and then place the porcelain boat in a tube furnace for calcination. Before calcination, pass argon for 30 minutes, and then raise the temperature at 3°C / min under argon The rate was raised from room temperature to 600°C for 4 hours of calcination. After the calcination was completed, it was cooled to room temperature with the furnace and ground to obtain the intermediate product B.

[0055] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com