High-stability perovskite solar cell based on sulfate doping

A solar cell, perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to protect perovskite films from moisture and oxygen erosion, weak secondary bonds, etc. Effects of current and photoelectric conversion efficiency, improved transfer rate, film quality, and improved humidity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

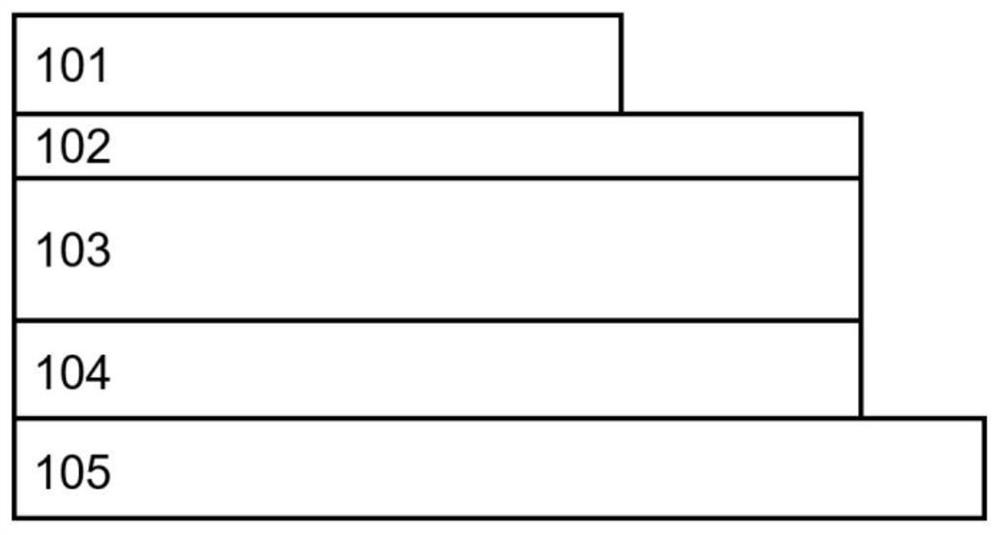

[0050] Sulfate-free perovskite solar cell devices

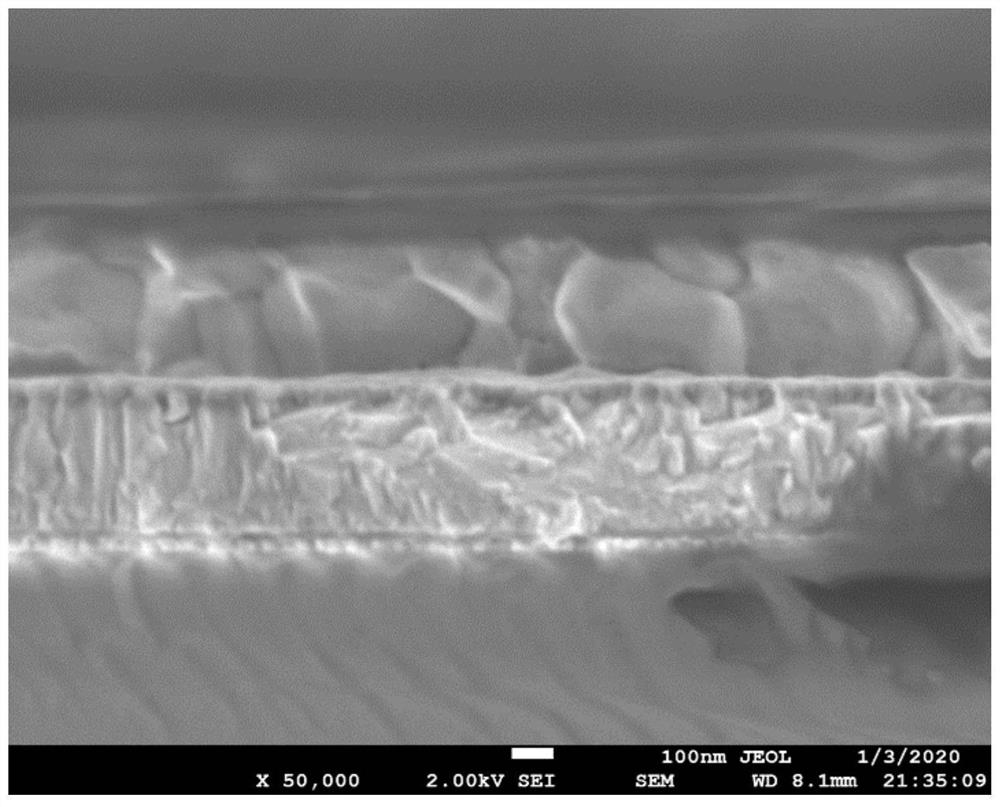

[0051] figure 2 It is the physical cross-sectional view of the device obtained by SEM scanning electron microscope, and its preparation process is as follows:

[0052] Step (1) Select the FTO conductive glass with a square resistance of 5-25Ω, a transmittance of 70-95%, and a size of 2cm*2cm as the substrate, then clean it with detergent, distilled water, ethanol and acetone, and finally use ultraviolet light to clean it. -Ozone machine for treatment.

[0053] Step (2) preparation of electron transport layer

[0054] SnO with a mass percent concentration of 15% 2 The colloidal aqueous solution and deionized water were mixed at a volume ratio of 1:6 to prepare SnO 2 Precursor solution, drop 80 μl of precursor solution on the FTO conductive glass per square centimeter through a pipette gun, and spin-coat at 5000rpm for 30s to deposit 30nm thick SnO 2 dense layer, and annealed at 100°C and 150°C for 10 minutes and 25 minut...

Embodiment 2

[0062] A perovskite solar cell device based on sulfate doping

[0063] Except for step (3), all steps and methods are identical to the foregoing Example 1.

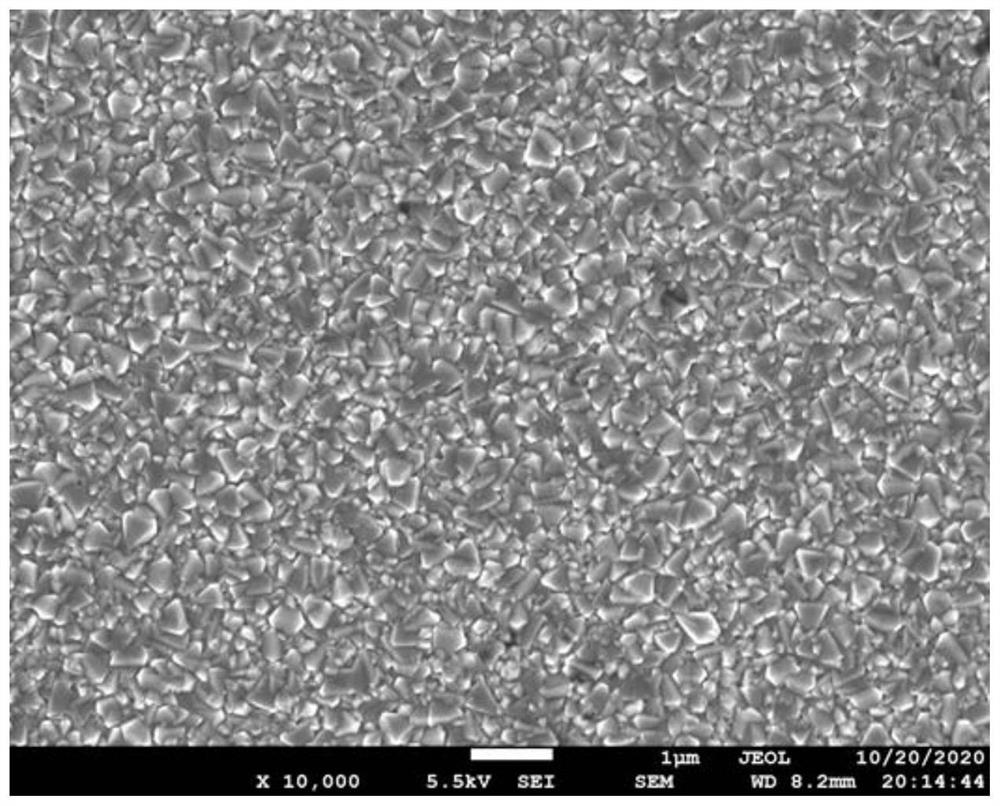

[0064] Step (3) Preparation of sulfate-doped perovskite light-absorbing layer by solution method

[0065] Dissolve 60mg of methylamine sulfate in 1ml of DMSO solution to prepare sulfate precursor solution; 1mmol of FAI, 0.9-1.2mmol of PbI 2 , 0.2mmol of MABr, 0.075mmol of CsI, 0.2mmol of PbBr 2 Prepare the perovskite precursor solution by dissolving 1ml of DMF and DMSO mixed solvent with a volume ratio of 4:1; add 50 μl of the sulfate precursor solution to 1 mL of the above perovskite precursor solution; stir and dissolve at room temperature, 3.8 wt% methylamine sulfate-doped Cs were obtained 0.05 (FA 0.85 MA 0.15 ) 0.95 Pb(I 0.85 Br 0.15 ) 3 Perovskite Precursor. SnO per square centimeter by pipetting 2 60 μl of perovskite precursor solution was added dropwise on the dense layer, the spin coating speed was 400...

Embodiment 3

[0067] A perovskite solar cell device based on sulfate doping

[0068] Except for step (3), all steps and methods are identical to the foregoing Example 1.

[0069] Step (3) Sulfate-doped perovskite light-absorbing layer prepared by vacuum flash evaporation

[0070] Dissolve 120mg of methylamine sulfate in 1ml of DMSO solution to prepare sulfate precursor solution; 1mmol of FAI, 0.9-1.2mmol of PbI 2 , 0.2mmol of MABr, 0.075mmol of CsI, 0.2mmol of PbBr 2 Dissolved in 1ml of DMF and NMP mixed solvent with a volume ratio of 8:1 to prepare a perovskite precursor solution; take 50 μl of sulfate precursor solution and add it to the above perovskite precursor solution; stir and dissolve at room temperature to obtain 7.5 wt% methamine sulfate doped Cs 0.05 (FA 0.85 MA 0.15 ) 0.95 Pb(I 0.85 Br 0.15 ) 3 Precursor. Spin-coat 60 μl of the above perovskite precursor solution on each square centimeter of SnO 2 On the dense layer, the rotation speed is 6000rmp, and the time is 10s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com