Extra-high voltage rod-shaped composite insulator

A composite insulator, UHV technology, applied in the direction of organic insulators, insulators, rubber insulators, etc., can solve the problems of loss of strength of insulators, excessive expansion coefficient of harmful stress, poor insulation effect, etc., to improve strength and dispersion performance, improve Solvent resistance and surface toughness, the effect of improving mechanical strength and insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

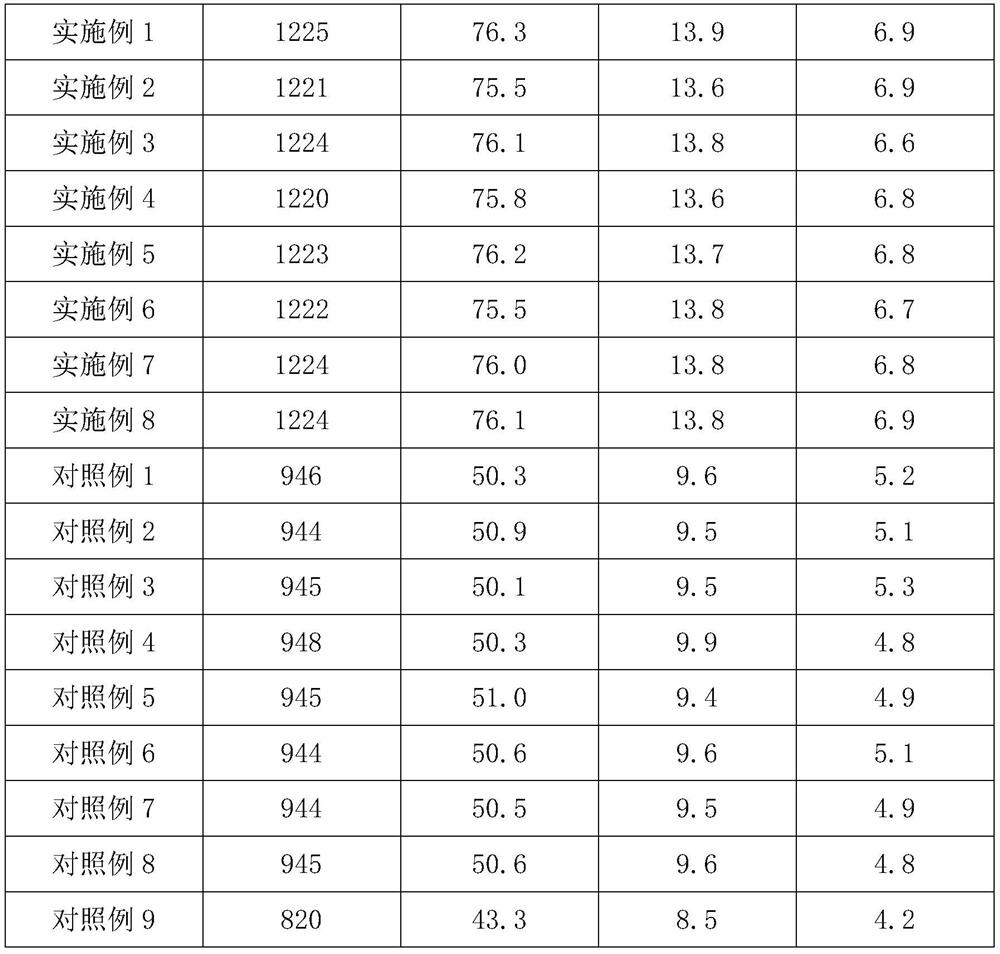

Examples

Embodiment 1

[0027] An ultra-high voltage rod-shaped composite insulator, comprising the following components in parts by weight: 32 parts of vinyl silicone rubber, 25 parts of polyketone resin, 16 parts of polycarbonate, 10 parts of zinc dimethyl dithiocarbamate, acrylic acid 15 parts of lauryl ester, 12 parts of ethylene-vinyl acetate copolymer, 4 parts of microcrystalline paraffin, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 3 parts of silane coupling agent, 1 part of ketoxime crosslinking agent, three layers 20 parts of core-shell structure zirconia insulating filler, 8 parts of basalt fiber, 0.6 part of plasticizer, 6 parts of aluminum hydroxide, 5 parts of white carbon black, 1 part of silicon micropowder; the three-layer core-shell structure zirconia insulating filler is composed of zirconia It consists of a core body, a polydopamine binding layer and a silicon nitride shell.

[0028] Among them, the preparation method of the three-layer core-shell structure zi...

Embodiment 2

[0033] An ultra-high voltage rod-shaped composite insulator, comprising the following components in parts by weight: 35 parts of vinyl silicone rubber, 30 parts of polyketone resin, 16 parts of polycarbonate, 10 parts of zinc dimethyl dithiocarbamate, acrylic acid 12 parts of lauryl ester, 15 parts of ethylene-vinyl acetate copolymer, 5 parts of microcrystalline paraffin, 1.2 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 3 parts of silane coupling agent, 0.5 parts of ketoxime crosslinking agent, three layers 20 parts of core-shell structure zirconia insulating filler, 5 parts of basalt fiber, 0.6 parts of plasticizer, 8 parts of aluminum hydroxide, 4 parts of white carbon black, 2 parts of silicon micropowder; the three-layer core-shell structure zirconia insulating filler is composed of zirconia It consists of a core body, a polydopamine binding layer and a silicon nitride shell.

[0034] Among them, the preparation method of the three-layer core-shell stru...

Embodiment 3

[0039] An ultra-high voltage rod-shaped composite insulator, comprising the following components in parts by weight: 30 parts of vinyl silicone rubber, 20 parts of polyketone resin, 15 parts of polycarbonate, 5 parts of zinc dimethyl dithiocarbamate, acrylic acid 10 parts of lauryl ester, 10 parts of ethylene-vinyl acetate copolymer, 4 parts of microcrystalline paraffin, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 2 parts of silane coupling agent, 0.5 part of ketoxime crosslinking agent, three layers Core-shell structure zirconia insulating filler 20 parts, basalt fiber 5 parts, plasticizer 0.5 part, aluminum hydroxide 5 parts, white carbon black 2 parts, silica powder 1 part; three-layer core-shell structure zirconia insulating filler is composed of zirconia It consists of a core body, a polydopamine binding layer and a silicon nitride shell.

[0040] Among them, the preparation method of the three-layer core-shell structure zirconia insulating filler is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com