Solid-state lithium battery

A solid-state lithium and solid-state electrolyte technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve problems such as poor contact between electrodes and electrolyte interfaces, low conductivity, etc., and achieve improved solid-state battery performance, stable interface, and cycle stability and the effect of improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

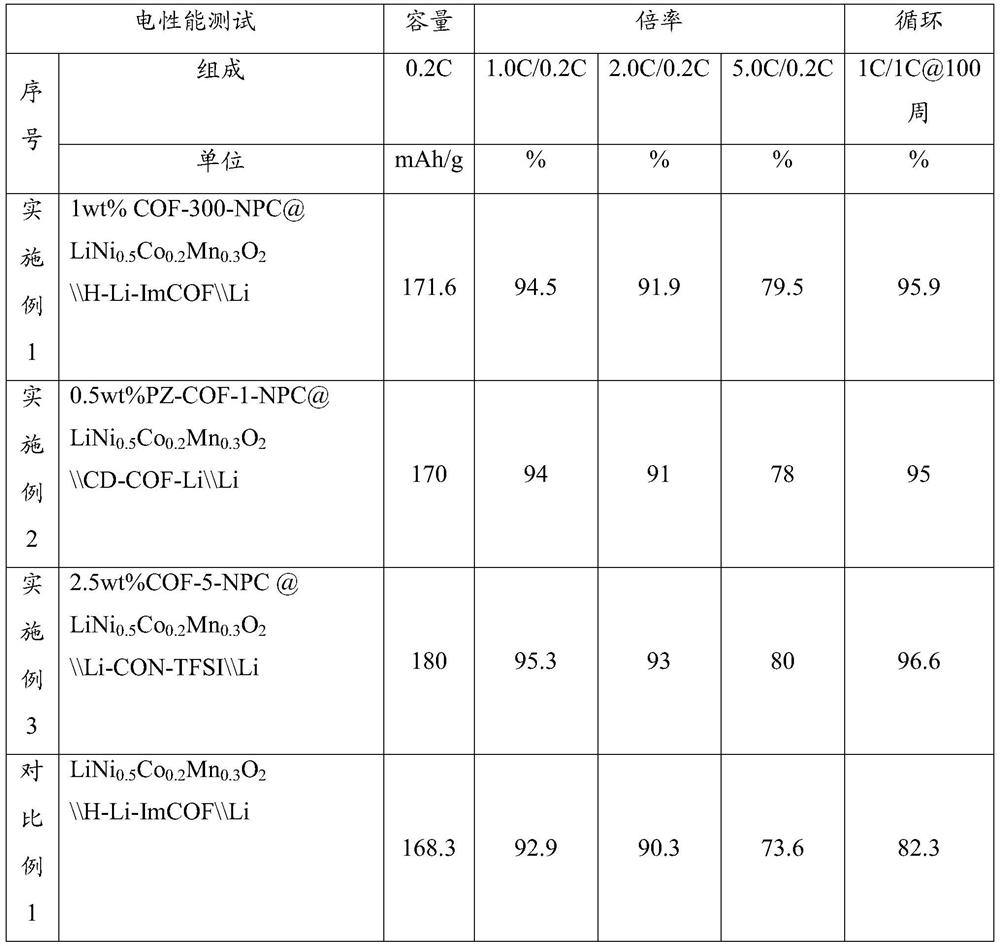

Embodiment 1

[0087] Co-precipitation and solid-state sintering method to prepare nickel-cobalt-lithium manganese oxide ternary material LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0088] Preparation of COF-300 by solvothermal method: Weigh tetraaminetetraphenylmethane and terephthalaldehyde into a polytetrafluoroethylene-lined autoclave, inject dried anhydrous dioxane and 3M acetic acid aqueous solution, and make After the solid powder was completely dissolved, it was placed in a 120°C drying oven to react for 3 days. After the reaction, the yellow powder obtained was filtered, washed repeatedly with anhydrous dioxane and anhydrous tetrahydrofuran, activated with anhydrous tetrahydrofuran, and dried in vacuum to obtain COF- 300 powder.

[0089] Combining COF-300 with LiNi 0.5 co 0.2 mn 0.3 o 2 Add it to the ball mill tank, add the small and medium balls with a mass ratio of 0.5:1 to the nickel-cobalt lithium manganate ternary material, the mass ratio of the small and medium balls is 1:1, and mi...

Embodiment 2

[0093] Co-precipitation and solid-state sintering method to prepare nickel-cobalt-lithium manganese oxide ternary material LiNi 0.5 co 0.2 mn 0.3 o 2 . Preparation of PZ-COF-1 powder by solvothermal method: 1,2,4,5-tetraaminobenzene (110.0mg, 1.0mmol) and hexahydroxytriphenylene (108.0mg, 1.0mmol) were placed in polytetrafluoroethylene Into a lined autoclave, inject 5 mL of acetic acid, and then add potassium dichromate (100.0 mg, 0.3 mmol) to completely dissolve the solid powder. Then the reaction kettle was placed in a drying oven at 120° C. for 3 days to react, and a black suspension was obtained after the reaction was completed.

[0094] Among them, acetic acid is used as a catalyst to promote the dehydration reaction of the first step, and potassium dichromate is used as an oxidant for the second step oxidation reaction.

[0095] The obtained black suspension was filtered, and the obtained precipitate was repeatedly washed with tetrahydrofuran. After vacuum drying, ...

Embodiment 3

[0100] Co-precipitation and solid-state sintering method to prepare nickel-cobalt-lithium manganese oxide ternary material LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0101] COF-5 powder was prepared by solvothermal method: 1,4-benzenediboronic acid (BDBA; 185mg, 1.116mmol) and 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP; 241.5mg, 0.745mmol ) into a polytetrafluoroethylene-lined reaction kettle, inject 20mL of a 1:1 volume solution of 1,3,5-trimethylbenzene and 1,4-dioxane to completely dissolve the solid powder. Then the reaction kettle was placed in a drying oven at 100° C. for 3 days.

[0102] The obtained suspension was filtered, and the obtained precipitate was repeatedly washed with acetone. After vacuum drying, COF-5 powder is obtained, which is a boron-containing COFs material.

[0103] Combine the prepared COF-5 powder with LiNi 0.5 co 0.2 mn 0.3 o 2 Add it to the ball mill tank, add the small and medium balls with a mass ratio of 0.5:1 to the nickel-cobalt lithium manga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com