Amine co-initiator as well as preparation method and application thereof

A technology of co-initiator and photoinitiator, applied in the direction of organic chemistry, etc., can solve the problems of insufficient oxygen inhibition inhibition performance, low curing rate, and high yellowing, so as to improve the surface curing effect, inhibit oxygen polymerization, and reduce yellowing. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

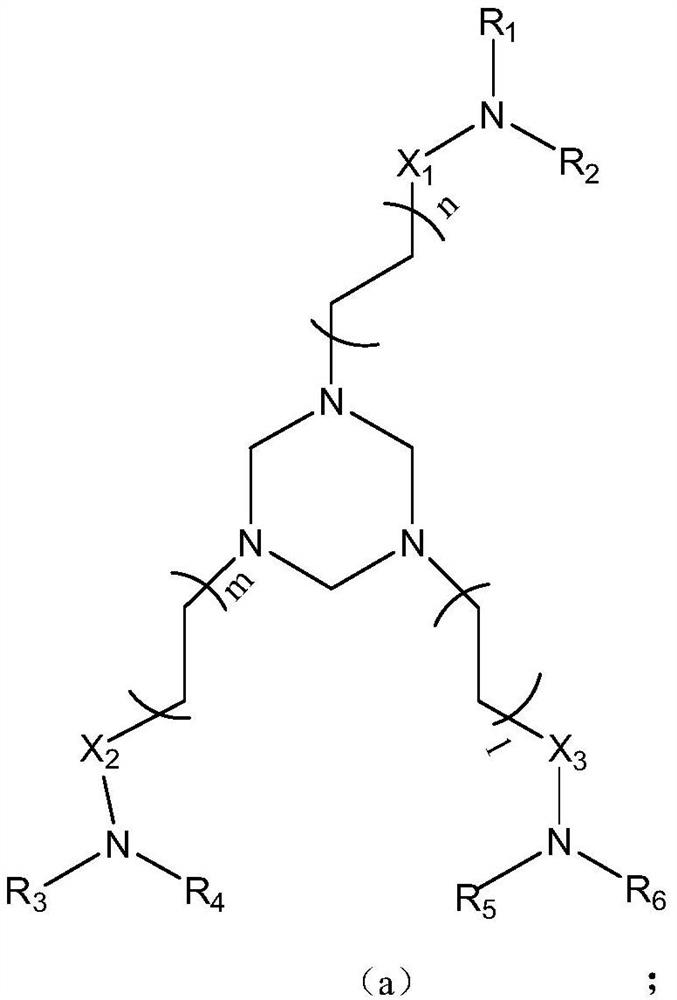

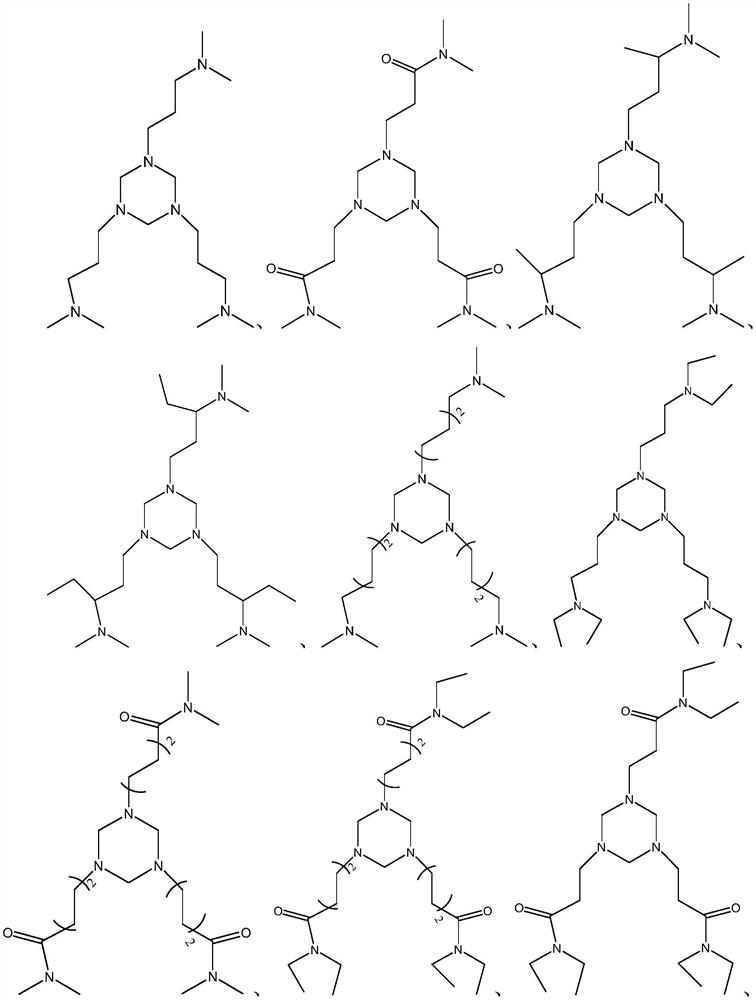

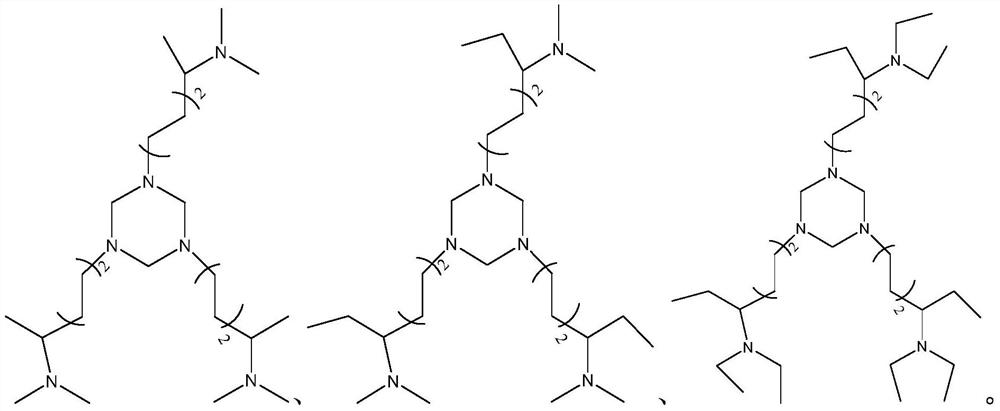

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a photocurable composition, which includes a base material, a hydrogen abstraction type photoinitiator and an amine co-initiator;

[0059] In the present embodiment, the hydrogen abstraction type photoinitiator adopts ITX, and the co-initiator is PC-41;

[0060] Wherein the preparation method of PC-41 is as follows, specifically comprises the following steps;

[0061] (a) Under the condition of heating and stirring, add N,N dimethylaminopropylamine dropwise to the formaldehyde solution, the molar ratio of formaldehyde to N,N dimethylaminopropylamine is 1:1; control the reaction temperature to 50°C, N , after the dropwise addition of N-dimethylaminopropylamine, continue to control the temperature and stir the reaction for 1.5h;

[0062] (b) cooling the reaction solution in step (a) in an ice-water bath, adding potassium hydroxide, controlling the temperature below 25°C, separating the organic phase, and then vacuum distillation to obtain PC-41; ...

Embodiment 2

[0073] The difference between this example and Example 1 is that the mass percentage of the amine co-initiator is 5%, the base material accounts for 92.5%, and the rest is ITX; other parameters and conditions are exactly the same as those in Example 1.

Embodiment 3

[0075] The difference between this embodiment and Embodiment 1 is that ITX quality is replaced by JRCure-1508, and other parameters and conditions are exactly the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com