Low-temperature denitrification catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as the inability to meet the denitration requirements of non-electrical industries, improve low-temperature denitration activity, and enhance anti-sulfur poisoning ability. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

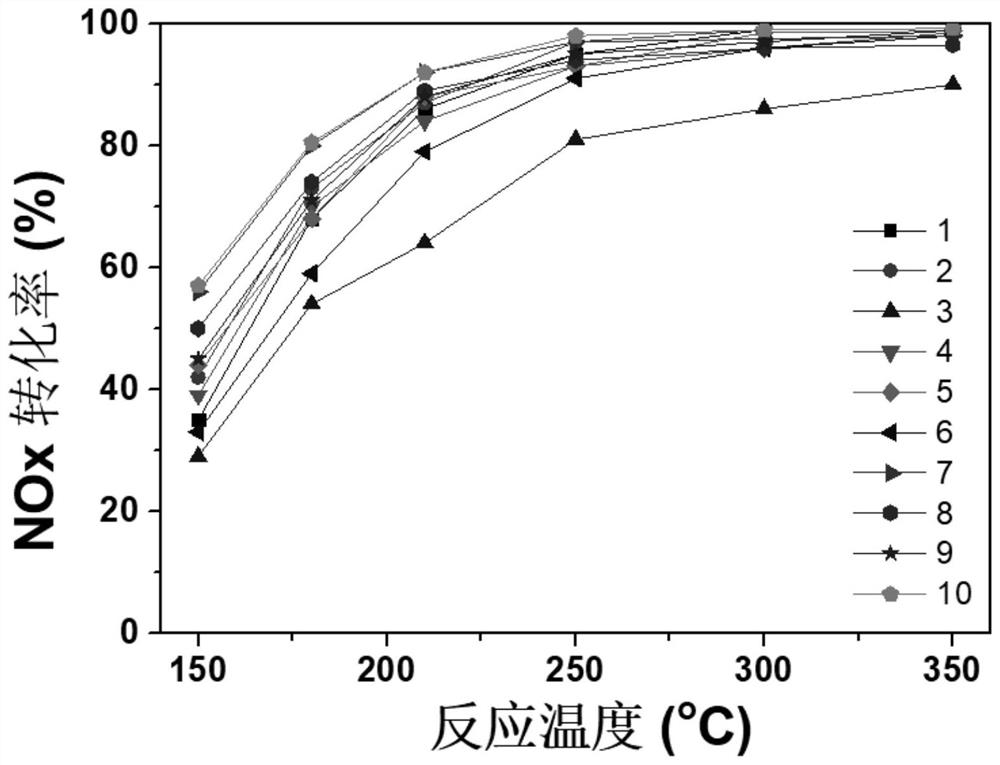

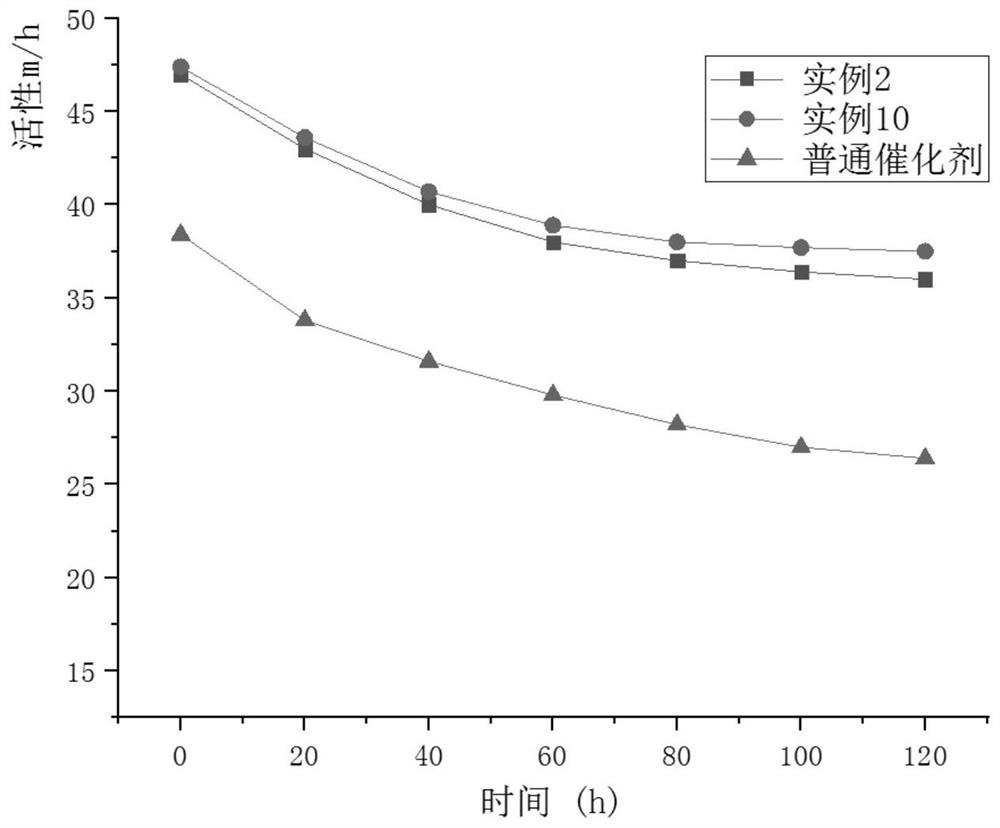

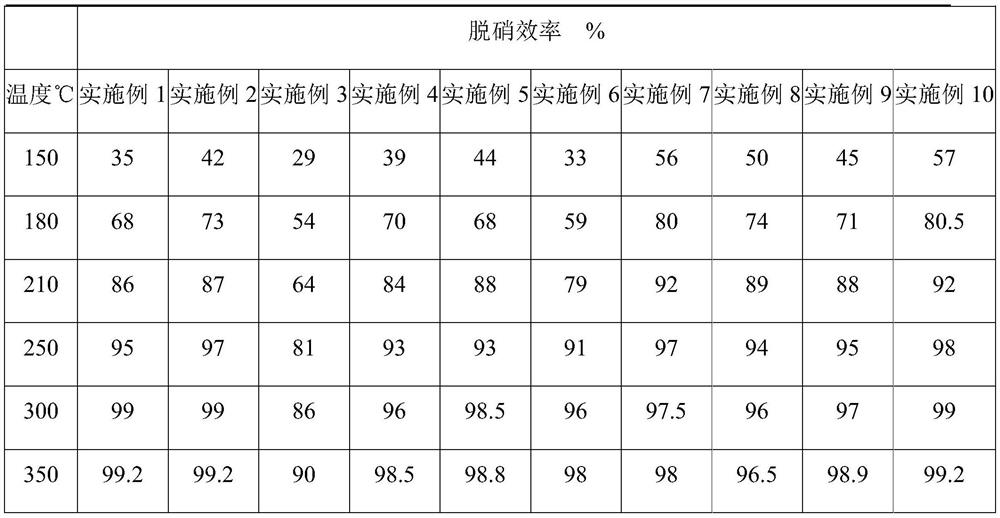

Examples

Embodiment 1

[0034] Accurately weigh quantitative sodium chloride and hydrochloric acid according to the halogen salt / halogen acid molar ratio of 0.5, and prepare a polarizing solution with a halogen ion molar concentration of 0.5mol / L and a mass of 1000g, and place the polarizing solution in a polytetrafluoroethylene container Accurately weigh quantitative cerium nitrate according to the metal / halogen ion molar ratio of 0.5, put it into a polytetrafluoroethylene container equipped with polarizing solution, seal the container after fully dissolving and heat it to 180°C for 24 hours and then drop to room temperature. Then filter and wash to obtain the cerium oxychloride precursor; Accurately weigh quantitative titanium dioxide according to the mass percentage of active component / carrier 10%, take the carrier mass as a benchmark, add 0.5% stearic acid, 3 % lactic acid and an appropriate amount of deionized water, and mixed for the first time; according to the mass percentage content of 10% of...

Embodiment 2

[0036] Accurately weigh quantitative potassium chloride and hydrochloric acid according to the halogen salt / halogen acid molar ratio of 3, and prepare a polarizing solution with a molar concentration of 0.1mol / L of halogen ions and a mass of 1000g, and place the polarizing solution in a polytetrafluoroethylene container Accurately weigh quantitative ammonium metavanadate according to the metal / halogen ion molar ratio of 0.25, put it into a polytetrafluoroethylene container equipped with polarizing solution, seal the container after fully dissolving and heat it to 120°C for 36 hours and then drop to room temperature, then filter and wash to obtain the vanadium oxychloride precursor; accurately weigh quantitative diatomite according to the mass percentage of the active component / carrier at 5%, and add 1% stearin to the carrier based on the mass of the carrier Acid, 5% lactic acid and an appropriate amount of deionized water are mixed for the first time; according to the mass perc...

Embodiment 3

[0038]Accurately weigh quantitative sodium fluoride and hydrofluoric acid according to the molar ratio of halogen salt / halogen acid 2, and make a polarizing solution with a molar concentration of halogen ions of 2mol / L and a mass of 1000g, and place the polarizing solution in a polytetrafluoroethylene container Medium: Accurately weigh the quantitative copper nitrate according to the metal / halide ion molar ratio of 0.75, put it into the polytetrafluoroethylene container with the polarizing solution, seal the container after fully dissolving and heat it to 210°C for 12 hours, then cool down to room temperature , then filter and wash to obtain the copper oxyfluoride precursor; accurately weigh quantitative alumina powder according to the mass percentage of the active component / carrier of 15%, and add 2% stearic acid to the carrier based on the carrier mass , 4% lactic acid and an appropriate amount of deionized water for the first mixing; according to the mass percentage of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com