Composite fiber material for wig and preparation method of composite fiber material

A composite fiber and wig technology, which is applied in the direction of wigs, fiber chemical characteristics, applications, etc., can solve the problems of unsatisfactory breaking strength and elongation of composite fibers, skin-friendly, poor air permeability and hygroscopicity, and air permeability and skin-friendly effects. problems such as poor, to achieve excellent high hygroscopicity, improve compatibility, improve spinnability and water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

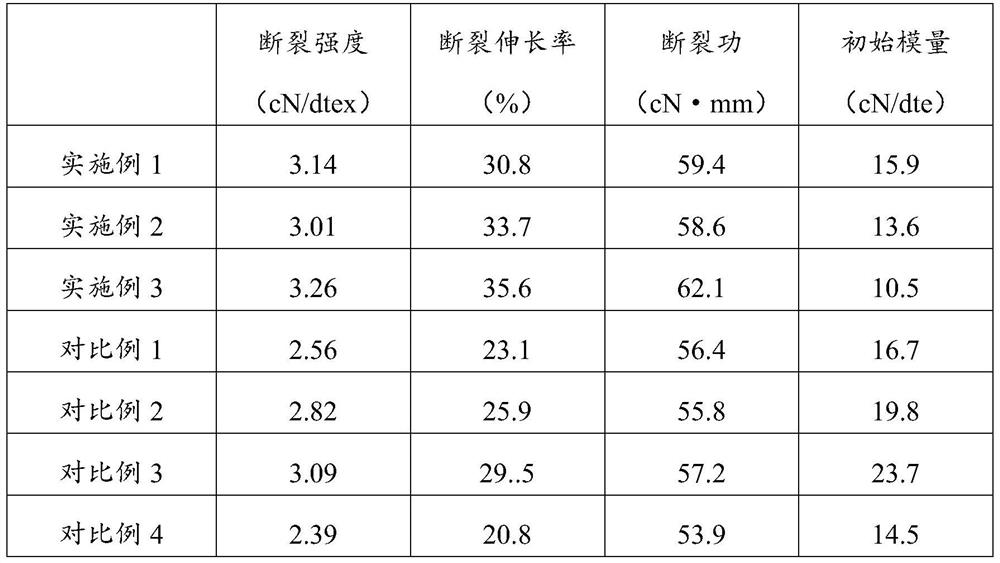

Examples

preparation example Construction

[0032] The preparation method of the pig hair keratin solution in the present invention is as follows: the pig hair is cleaned, impurity-removed and dried, then pulverized, and then mixed evenly with 0.5 mol / L tributyl phosphine solution, and the temperature is raised to 60-70°C , stirred and reacted for 2-3h, then dropped into NaOH solution to adjust the pH value to 7.5-8.5, and then centrifuged to remove solid impurities to obtain a pure pig hair protein solution. The protein with a molecular weight cut-off of dialysis bag of 5000-10000 was selected to make The protein content in the pig hair protein solution reaches 8-12%, and the required pig hair keratin solution is obtained. Wherein, the solute mass of the tributyl phosphine solution is 5-8% of the dry weight of pig hair after pulverization.

[0033] The preparation method of the wool keratin solution in the present invention is as follows: wash, remove impurities, and dry the wool, then pulverize it, add 0.5mol / L tribut...

Embodiment 1

[0035] Embodiment 1 A kind of composite fiber material for wig

[0036] A preparation method of a composite fiber material for a wig specifically comprises the following steps:

[0037] (1) Preparation of grafted PBAT: Put 30 parts of PBAT (polybutylene adipate / butylene terephthalate) into 90 parts of phenol / trichloromethane prepared by phenol and chloroform with a mass ratio of 3:1 In the methane solution, raise the temperature to 40°C, stir until dissolved, then add 0.3 parts of potassium persulfate and 6 parts of 1,2,4-1H-triazole, raise the temperature to 90°C, stir for 3 hours to prepare the grafted PBAT solution.

[0038] (2) Preparation of modified keratin: Put 80 parts of montmorillonite / sodium alginate modification solution, 25 parts of hair keratin solution and 3 parts of cross-linking agent sodium periodate into the reaction kettle, and heat up to 70°C , stirred for 3 hours to obtain modified keratin. The hair keratin solution is prepared by compounding pig hair k...

Embodiment 2

[0045] Embodiment 2 A kind of composite fiber material for wig

[0046] A preparation method of a composite fiber material for a wig specifically comprises the following steps:

[0047] (1) Preparation of grafted PBAT: Put 45 parts of PBAT into 225 parts of phenol / chloroform solution prepared by phenol and chloroform with a mass ratio of 3:1, heat up to 50 ° C, stir until dissolved, and then Add 1.35 parts of potassium persulfate and 22.5 parts of 1,2,4-1H-triazole, raise the temperature to 80°C, and stir for 5 hours to obtain a grafted PBAT solution.

[0048] (2) Preparation of modified keratin: put 60 parts of montmorillonite / sodium alginate modification solution, 10 parts of hair keratin solution and 2 parts of crosslinking agent dicyclohexylcarbodiimide (DCC) into the reactor , heated to 50°C and stirred for 3 hours to obtain modified keratin. The hair keratin solution is prepared by compounding pig hair keratin solution and wool keratin solution with a mass ratio of 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com