Texturing method for pretreating surface of monocrystalline silicon wafer by adopting electrochemical method

A single crystal silicon wafer, pretreatment technology, applied in chemical instruments and methods, after treatment, single crystal growth, etc., can solve the problems of increased battery production costs, high transportation and storage requirements, and large hydrogen peroxide consumption. Achieve the effect of simple structure, high transportation and storage costs, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for making texturing on the surface of a monocrystalline silicon wafer by the electrochemical method of the present embodiment specifically comprises the following steps:

[0034] (1) Immerse the solar monocrystalline silicon wafer in absolute ethanol, and ultrasonically clean it at 45-50°C for 5 minutes to remove impurities and organic pollution on the surface of the silicon wafer. Then take out the silicon chip, wash it with deionized water and dry it, then immerse it in the NaOH aqueous solution with a mass fraction of 10%, and soak it for 10 minutes at 85°C to remove the damaged layer on the surface of the silicon chip, then take out the silicon chip and wash it with deionized water And tumble dry.

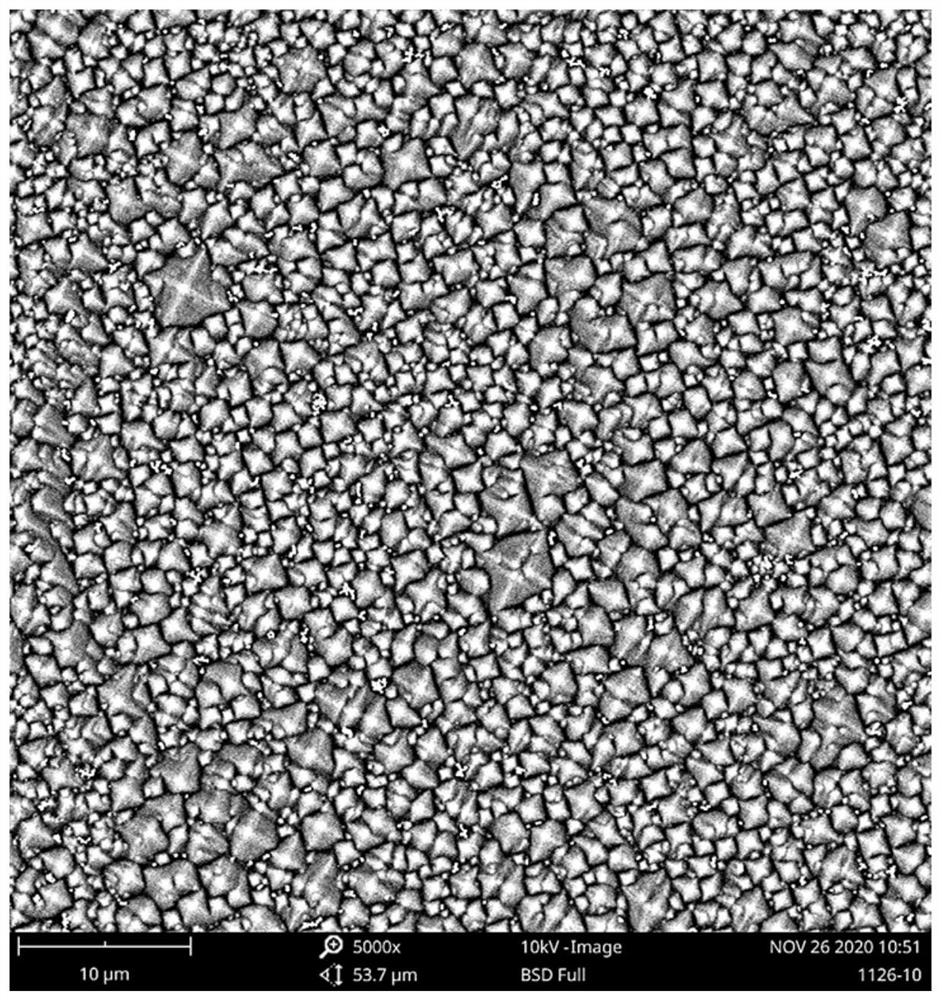

[0035] (2) Carry out electrochemical surface pretreatment to the monocrystalline silicon wafer after the above-mentioned step (1): immerse the silicon wafer in K of normal temperature 0.5mol / L 2 SO 4 In the solution, the silicon chip is used as the anode, a...

Embodiment 2

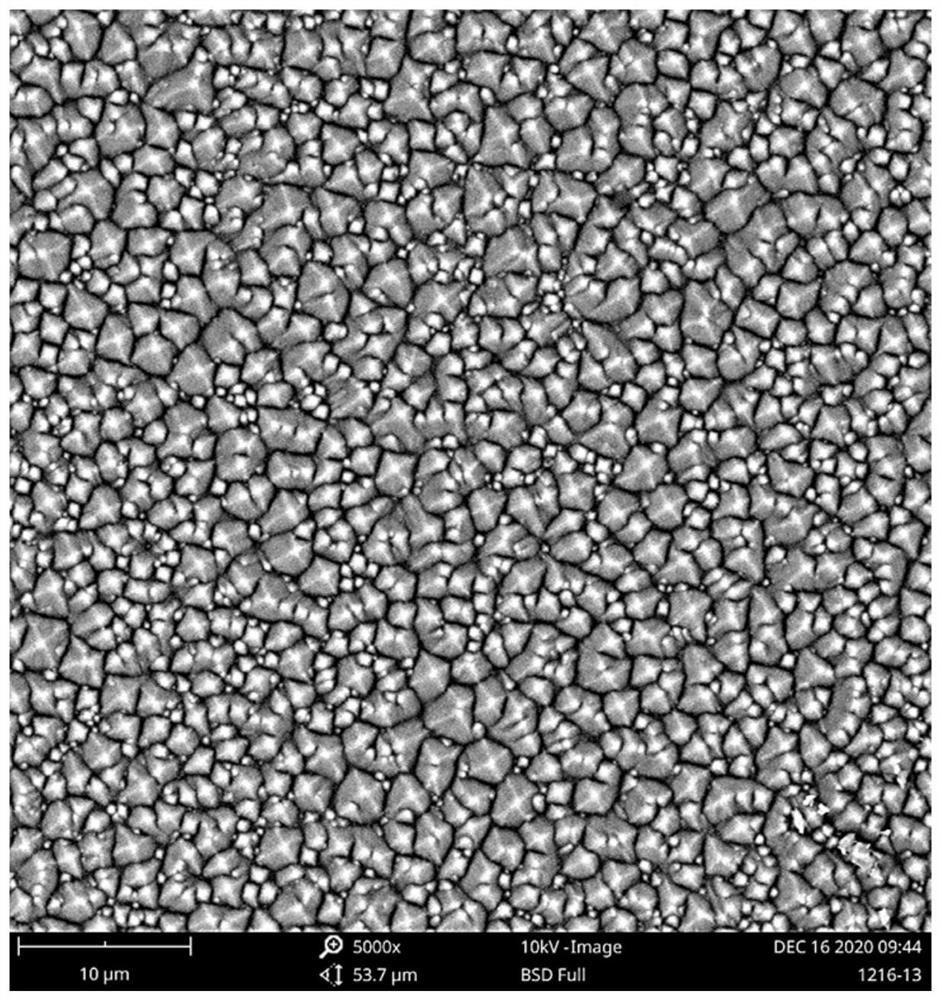

[0038] In this embodiment, the silicon wafer is immersed in a 0.5mol / L NaOH aqueous solution at normal temperature, and a DC constant voltage of 2.5V is applied between the anode silicon wafer and the cathode. The other steps are the same as in Example 1 to obtain a single crystal silicon wafer with a pyramid texture , see figure 2 .

Embodiment 3

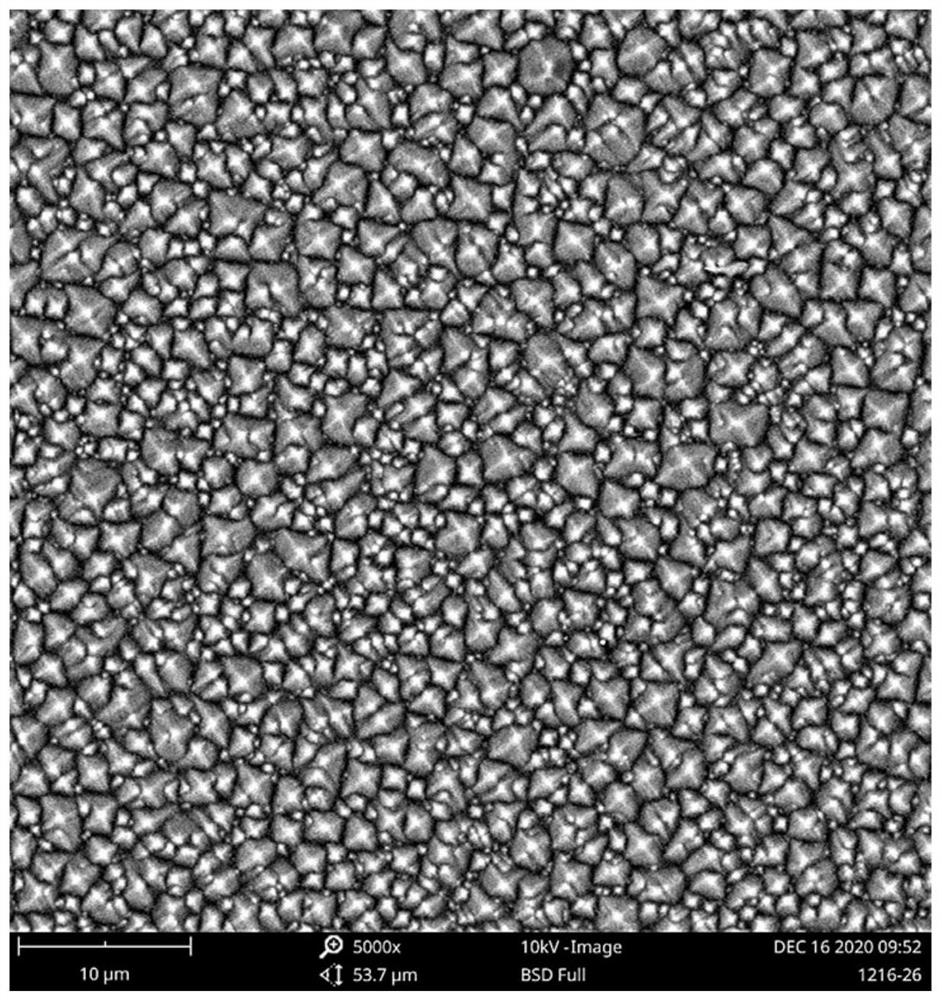

[0040] In this embodiment, the silicon wafer is immersed in a 0.5mol / L hydrochloric acid solution at normal temperature, and a DC constant voltage of 2.5V is applied between the anode silicon wafer and the cathode. The other steps are the same as in Example 1 to obtain a single crystal silicon wafer with a pyramid texture , see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com