Preparation method of Al modified SBA-15 and application of Al modified SBA-15 in catalyzing alkynol dehydration reaction

A technology of SBA-15 and dehydration reaction, which is applied in the direction of catalyst, sulfide preparation, halogenated hydrocarbon preparation, etc. It can solve the problems of difficult formation, metal hydrolysis and polymerization speed mismatch, etc., and achieve the effect of enhancing controllability and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

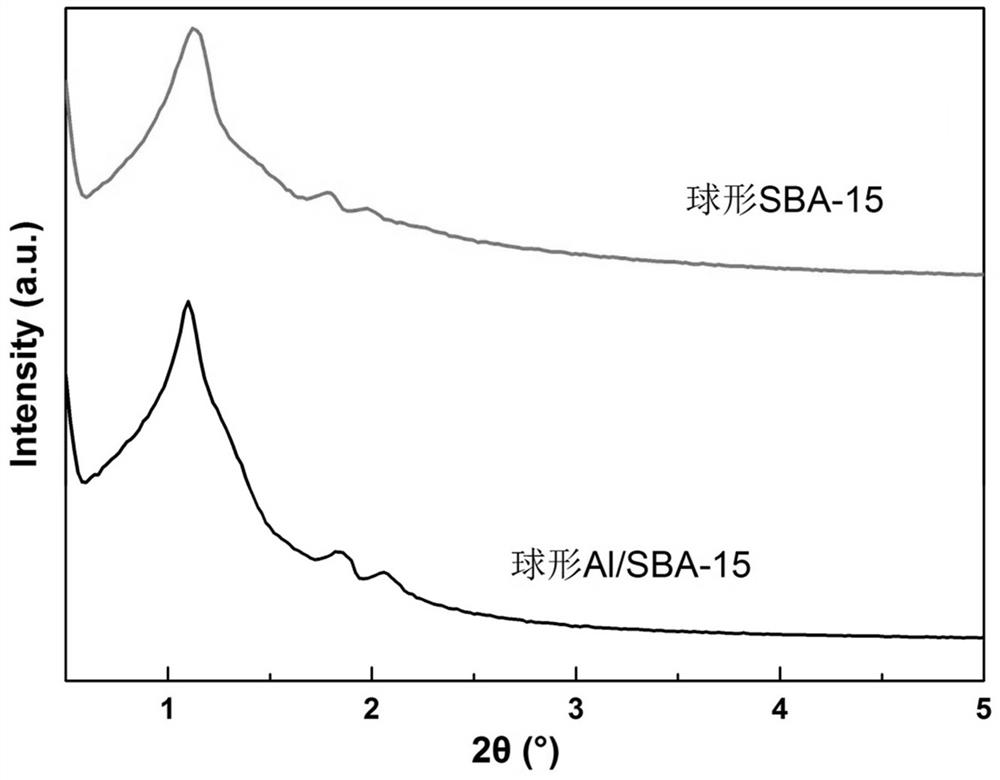

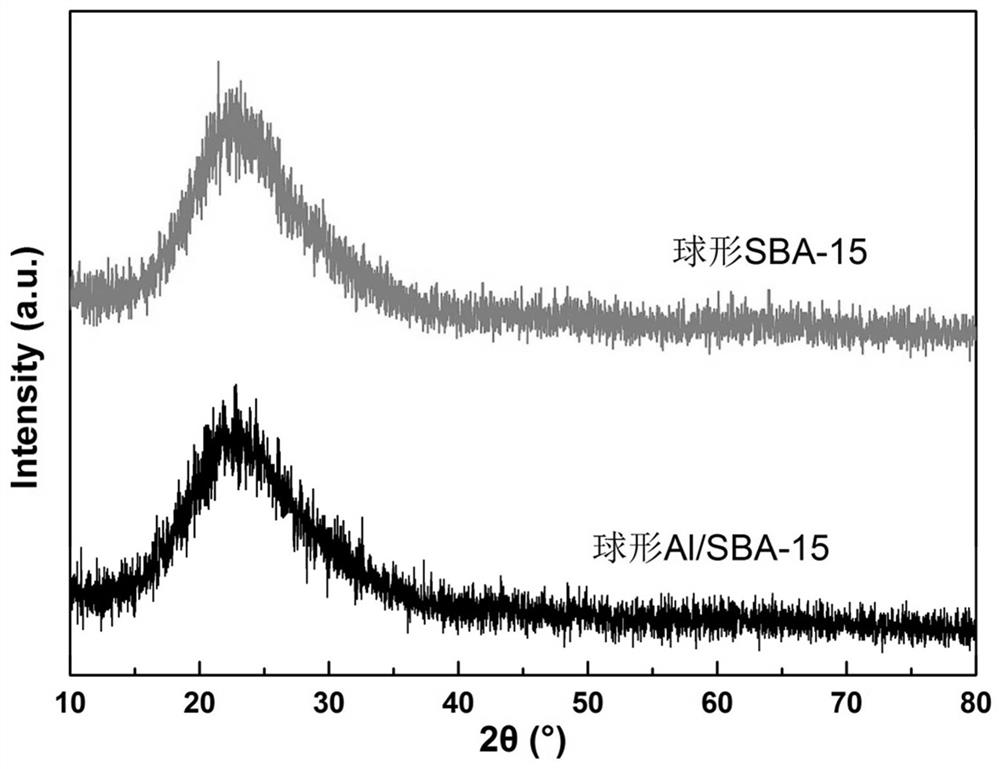

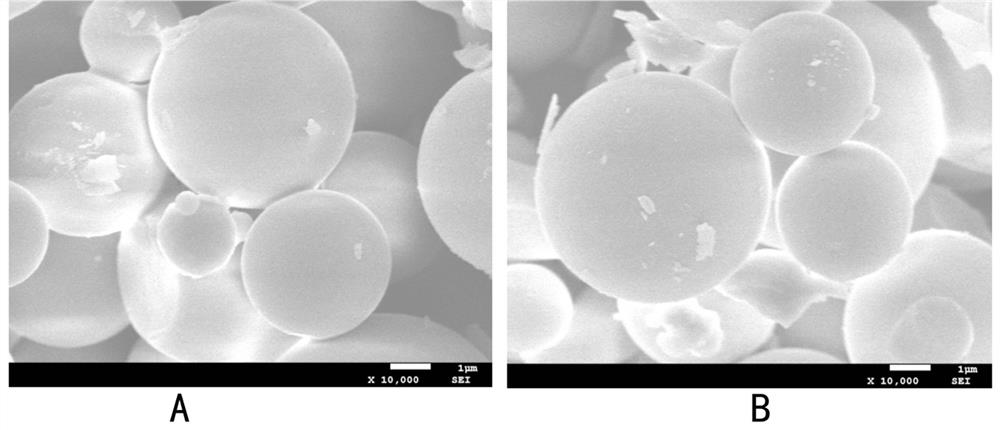

[0038] A preparation method of Al-modified SBA-15 containing only four-coordinated aluminum skeleton - mixing and stirring for 6 hours, crystallization at 120°C, the following is the specific implementation method:

[0039] Weigh 1.23g Al(NO 3 ) 3 9H 2 O aluminum source, it is added in the round bottom flask that fills the deionized water of 120mL, stirs under normal temperature, until Al(NO 3 ) 3 9H 2 O is completely dissolved until the solution is clear, then adjust the pH value of the solution, and the pH value of the solution is 2; then weigh 2 g of the prepared spherical SBA-15 mesoporous molecular sieve, slowly stir it into the aluminum-containing source solution, and continuously Stir, mix and stir for 6 hours and then stop stirring; transfer the obtained mixed solution into a polytetrafluoroethylene-lined crystallization kettle, and continue crystallization at 120°C for 24 hours; wash the crystallized solid with deionized water and absolute ethanol After washing a...

Embodiment 3

[0043] A preparation method of a terminal enyne compound - But-3-en-1-yne-1,3-diyldibenzene, the following is the specific implementation method (catalyst dosage 6mg):

[0044] Weigh compound acetylenic alcohol 1a 0.0222g (0.1mmol) (substituent R 1 , R 2 , R 3 Respectively phenyl, hydrogen, phenyl) are placed in a round-bottomed flask, measure 3mL of anhydrous toluene as a reaction solvent and pour it into it, stir to completely dissolve the acetylenic alcohol, weigh the Al / SBA-15 medium prepared in Example 1 Add 6mg of porous material catalyst into the reaction system, stir at a constant temperature in an oil bath at 110°C, condense and reflux; monitor the reaction with TCL, after 15 minutes the reaction of compound acetylenic alcohol 1a is complete, the system is cooled to room temperature and the solvent toluene is evaporated under reduced pressure, and the reaction system is passed through a silica gel column Column chromatography separation was carried out to obtain the...

Embodiment 4

[0049] A preparation method of a terminal enyne compound - But-3-en-1-yne-1,3-diyldibenzene, the following is the specific implementation method (catalyst dosage 3mg):

[0050] Weigh compound acetylenic alcohol 1a 0.0222g (0.1mmol) (substituent R 1 , R 2 , R 3 Respectively phenyl, hydrogen, phenyl) are placed in a round-bottomed flask, measure 3mL of anhydrous toluene as a reaction solvent and pour it into it, stir to completely dissolve the acetylenic alcohol, weigh the Al / SBA-15 medium prepared in Example 1 Add 3 mg of porous material catalyst to the reaction system, stir at a constant temperature in an oil bath at 110°C, condense and reflux; monitor the reaction with TCL, after 15 minutes the reaction of the compound acetylenic alcohol 1a is complete, the system is cooled to room temperature and the solvent toluene is evaporated under reduced pressure, and the reaction system is passed through a silica gel column The target product enyne 2a was obtained by column chromato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com