Polymer photoinitiator and preparation method thereof

A photoinitiator and polymer technology, applied in the field of polymer photoinitiator and its preparation, can solve the problems of uncontrollable chemical structure, low content of initiating group, uncontrollable molecular weight, etc., to overcome the problems of volatilization and migration, molecular weight The effect of narrow distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of macromolecular photoinitiator, specifically as follows:

[0051] Add 4,4'-dihydroxybenzophenone, dihalogenated hydrocarbon (1,10-dibromodecane) and inorganic base (potassium carbonate) into the solvent (acetone), and under nitrogen, the solvent is refluxed for polycondensation Reaction, the reaction temperature is 56°C, the reaction time is 4h, and the stirring speed is 300rpm; after the reaction, filter with suction, wash fully with water and methanol four times alternately, and vacuum dry at 80°C for 6h to obtain a polymer photoinitiator; Among them, the molar ratio of 4,4'-dihydroxybenzophenone to dihalogenated hydrocarbon is 1:1; the molar ratio of inorganic base to dihalogenated hydrocarbon is 2:1; 4,4'-dihydroxydiphenyl The ratio of the number of moles of ketone to the volume of solvent is 1mol:1L.

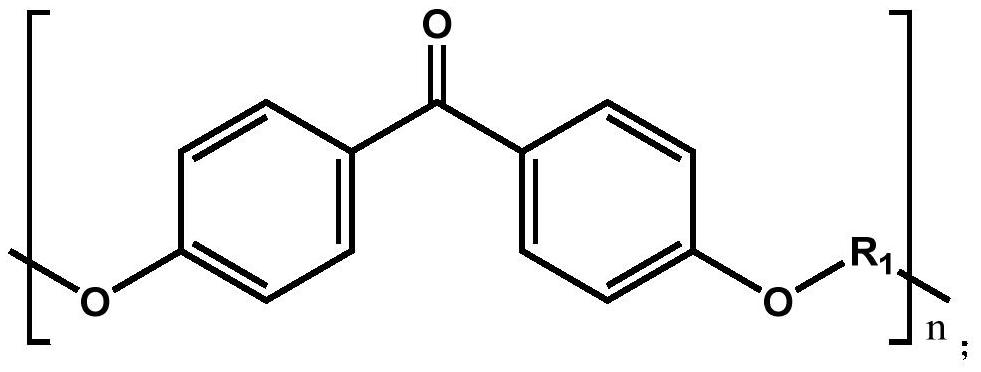

[0052] A kind of polymer photoinitiator prepared, its structural formula is:

[0053]

[0054] Among them, R 1 It is decylene; the numbe...

Embodiment 2

[0056] A preparation method of macromolecular photoinitiator, specifically as follows:

[0057] Add 4,4'-dihydroxybenzophenone, dihalogenated hydrocarbon (1,10-dibromodecane) and inorganic base (potassium carbonate) into the solvent (toluene), and under nitrogen, the solvent is refluxed for polycondensation Reaction, the reaction temperature is 110°C, the reaction time is 12h, and the stirring speed is 300rpm; after the reaction, filter with suction, wash fully with water and methanol four times alternately, and vacuum dry at 80°C for 6h to obtain a polymer photoinitiator; Among them, the molar ratio of 4,4'-dihydroxybenzophenone to dihalogenated hydrocarbon is 1:1; the molar ratio of inorganic base to dihalogenated hydrocarbon is 2:1; 4,4'-dihydroxydiphenyl The ratio of the number of moles of ketone to the volume of solvent is 2mol:1L.

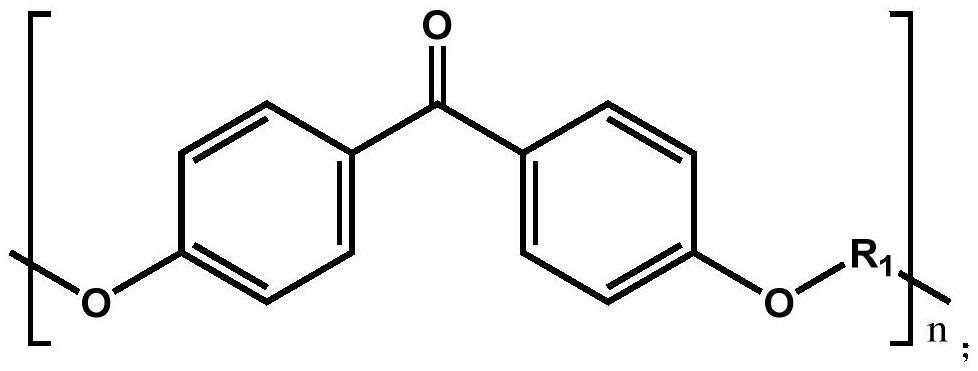

[0058] A kind of polymer photoinitiator prepared, its structural formula is:

[0059]

[0060] Among them, R 1 It is decylene; the num...

Embodiment 3

[0062] A preparation method of macromolecular photoinitiator, specifically as follows:

[0063] Add 4,4'-dihydroxybenzophenone, dihalogenated hydrocarbon (1,4-dibromobenzene) and inorganic base (sodium carbonate) into the solvent (propanol), and under argon, the solvent is refluxed Polycondensation reaction, the reaction temperature is 87°C, the reaction time is 16h, and the stirring speed is 300rpm; after the reaction, filter with suction, wash fully with water and methanol four times alternately, and vacuum dry at 80°C for 6h to obtain a polymer photoinitiator ; Wherein, the molar ratio of 4,4'-dihydroxybenzophenone and dihalogenated hydrocarbon is 0.95:1; the molar ratio of inorganic base and dihalogenated hydrocarbon is 2:1; 4,4'-dihydroxydihydrocarbon The ratio of the number of moles of benzophenone to the volume of solvent is 3mol:1L.

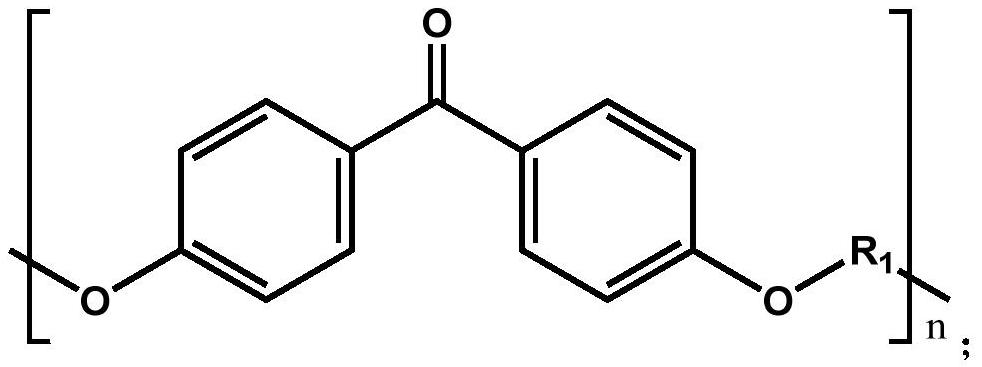

[0064] A kind of polymer photoinitiator prepared, its structural formula is:

[0065]

[0066] Among them, R 1 It is 1,4-phenylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com