Treatment method of chemical and chemical engineering waste liquid

A treatment method and technology for chemical wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve problems such as unstable treatment effect, blockage, and water quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

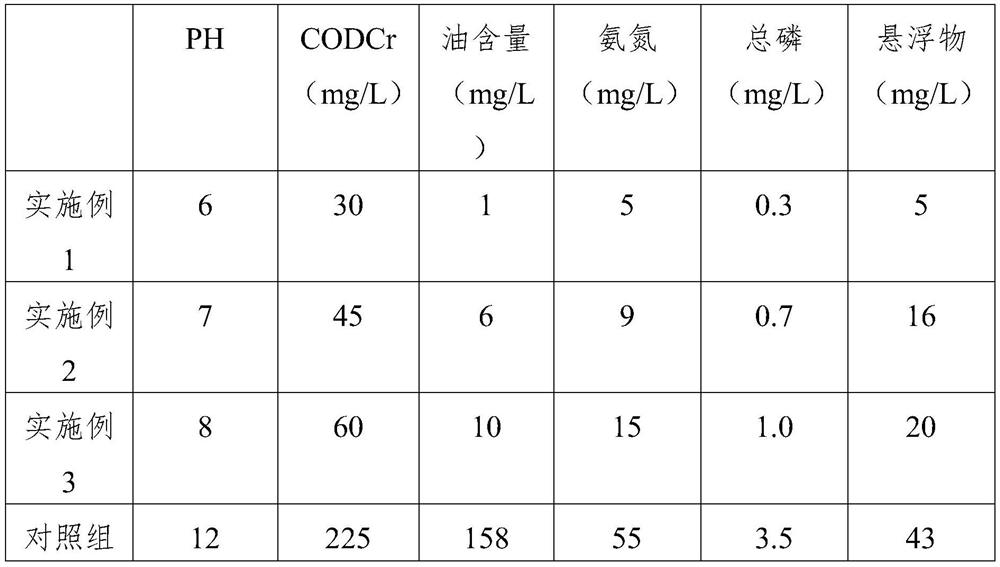

Embodiment 1

[0025] The invention provides a treatment method for chemical and chemical waste liquid, the specific steps are as follows:

[0026] Step 1: Oxidation treatment: Mix nitric acid and sodium hypochlorite at a ratio of 1:1 to make an oxidant, prepare ammonium persulfate with a molar ratio of 1:2 to the oxidant as an initiator, and use it to chemical wastewater with a BOD5 / COD value of 0.07 The oxidizing agent and the initiator added in the ratio of 5g / L and 1g / L in the water, carry out the oxidation reaction, and oxidize and decompose the organic matter in the waste water;

[0027] Step 2: Acid-base neutralization treatment: mix calcium hydroxide and ammonia water in a ratio of 1:1 to make an alkaline solution, add the alkaline solution to the wastewater, carry out acid-base neutralization reaction, adjust the pH value of the wastewater, and add After adding polyaluminum chloride to the wastewater, solid-liquid separation treatment is carried out to remove suspended solids in the...

Embodiment 2

[0033] The invention provides a treatment method for chemical and chemical waste liquid, the specific steps are as follows:

[0034] Step 1: Oxidation treatment: Mix nitric acid and sodium hypochlorite in a ratio of 2:3 to make an oxidant, prepare ammonium persulfate with a molar ratio of 1:3 to the oxidant as an initiator, and use it to chemical wastewater with a BOD5 / COD value of 0.15 The oxidizing agent and the initiator added in the ratio of 7g / L and 2g / L in the water are carried out to carry out the oxidation reaction, and the organic matter in the waste water is oxidized and decomposed;

[0035] Step 2: Acid-base neutralization treatment: mix calcium hydroxide and ammonia water in a ratio of 1:1.5 to make an alkaline solution, add alkaline solution to the wastewater, carry out acid-base neutralization reaction, adjust the pH value of the wastewater, and add After adding polyaluminium chloride to the wastewater, solid-liquid separation treatment is carried out to remove s...

Embodiment 3

[0041] The invention provides a treatment method for chemical and chemical waste liquid, the specific steps are as follows:

[0042] Step 1: Oxidation treatment: Mix nitric acid and sodium hypochlorite in a ratio of 3:5 to make an oxidant, prepare ammonium persulfate with a molar ratio of 1:5 to the oxidant as an initiator, and use it to chemical wastewater with a BOD5 / COD value of 0.25 The oxidizing agent and the initiator added in the ratio of 10g / L and 3g / L in the water are used for oxidation reaction, and the organic matter in the waste water is oxidized and decomposed;

[0043] Step 2: Acid-base neutralization treatment: mix calcium hydroxide and ammonia water in a ratio of 1:2 to make an alkaline solution, add the alkaline solution to the wastewater, carry out acid-base neutralization reaction, adjust the pH value of the wastewater, and add After adding polyaluminium chloride to the wastewater, solid-liquid separation treatment is carried out to remove suspended solids i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com