Method for performing surface modification on titanium-based implant and titanium-based implant surface composite coating

A surface composite and implant technology, applied in coating, metal material coating process, drug delivery, etc., can solve the problems of easy bacterial infection and implant loosening, and achieve inhibition of bacterial proliferation and good osseointegration , promote the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

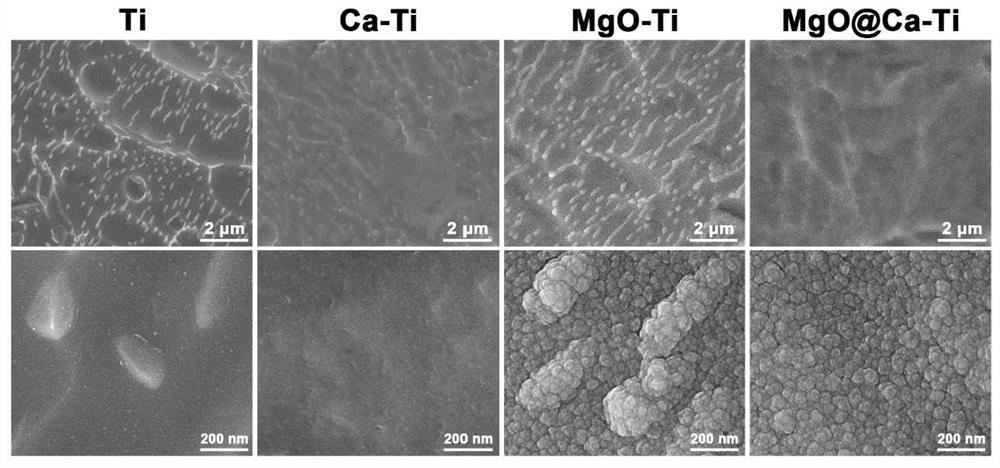

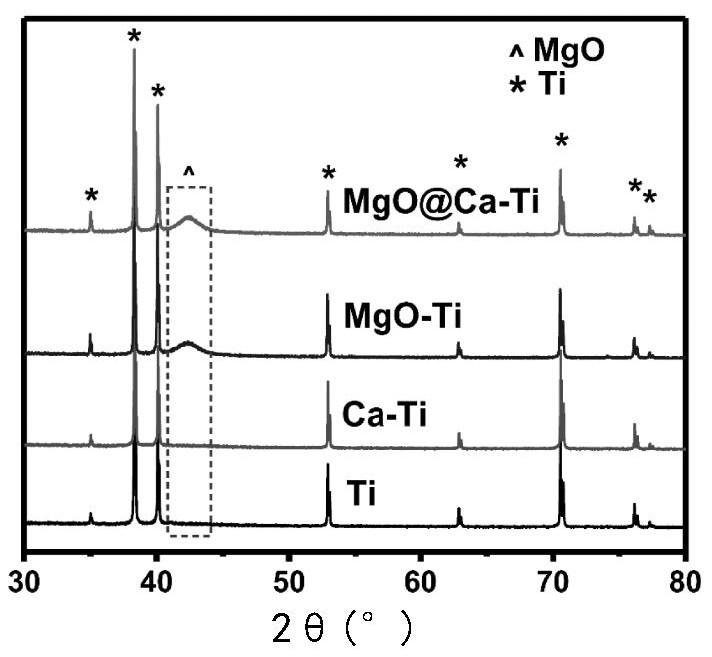

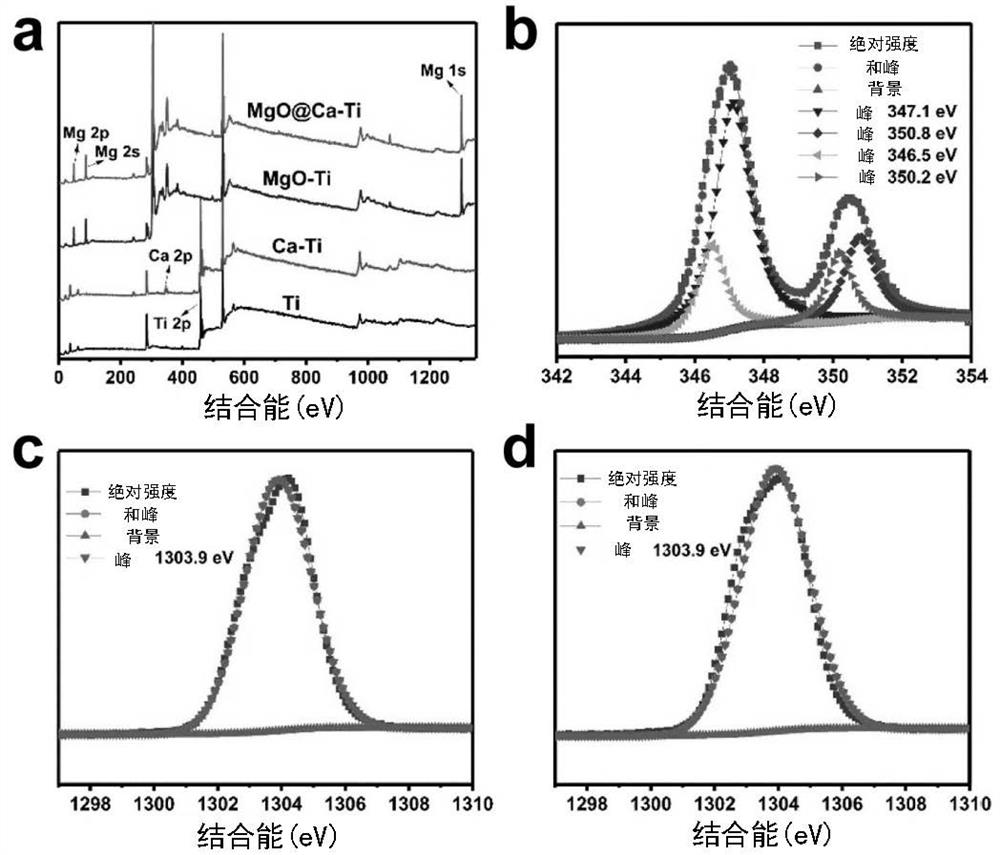

[0076] (1) The pure titanium metal sheet of 10mm×10mm×1mm was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, each time for 10 minutes, followed by ultrasonic pickling, and the pickling liquid was made of hydrofluoric acid, Nitric acid and ultrapure water are mixed at a volume ratio of 1:5:4; then deionized water is ultrasonically cleaned to obtain a clean and uniform surface, that is, an acid-washed titanium surface (indicated by Ti). The obtained surface is a rough microstructure, and it can be found that there are protrusions on the surface under a high-magnification microscope (see figure 1 shown).

[0077] (2) Using the plasma immersion ion implantation technique, selecting a metal calcium cathode, performing calcium ion implantation on the cleaned titanium surface, and constructing a Ca-Ti layer on the titanium surface. The specific process conditions and parameters are shown in Table 2. The morphology of the surface of the modifi...

Embodiment 2

[0087]The surface ion release amount of the titanium material obtained through the modification treatment of the above-mentioned Example 1 in physiological saline was analyzed and detected. Put the sample into a 15mL centrifuge tube, add 10mL of physiological saline, and soak at 37°C for 1, 4, 7, 14, 21, 35 and 49 days. The extract was collected at each time point, and 10 mL of fresh saline was added again. The contents of Mg and Ca ions in the collected leachate were tested by inductively coupled plasma atomic emission spectrometer (ICP-AES, Varian Liberty 150, USA).

[0088] Figure 5 It is the Mg ion ( Figure 5 5a) and Ca ions ( Figure 5 5b) release results. It can be seen from 5a that after soaking for 14 days, the release of Mg ions from the MgO-Ti and MgO@Ca-Ti samples was significantly reduced, indicating that the MgO film on the surface of the composite modified titanium sample can exist in normal saline for about 14 days; In 1, 4 and 7 days, the release rate of...

Embodiment 3

[0090] The alkalinity of the local microenvironment on the surface of the titanium material obtained through the modification treatment of the above-mentioned Example 1 in physiological saline was evaluated. Place the sample in a 15mL centrifuge tube, add 5mL of normal saline, and soak at 37°C for 24 hours. Using a pH meter (FE20-FiveEasy TM , METTLER TOLEDO) to measure the pH value of saline at each time point.

[0091] The pH values of normal saline after soaking Ti, Ca-Ti, MgO-Ti and MgO@Ca-Ti samples for 24 hours are as follows Figure 6 shown. The pH values of the normal saline in the Ti and Ca-Ti sample groups are similar, while the pH values of the normal saline in the MgO-Ti and MgO@Ca-Ti sample groups are both over 10, which is significantly higher than that in the Ti sample group, indicating that the surface of the MgO film can quickly form an alkaline Microenvironment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com