Vertical Ga2O3 nanotube ordered array and preparation method thereof

A technology of ordered arrays and nanotubes, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve difficult problems such as direction, length, size and tube wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

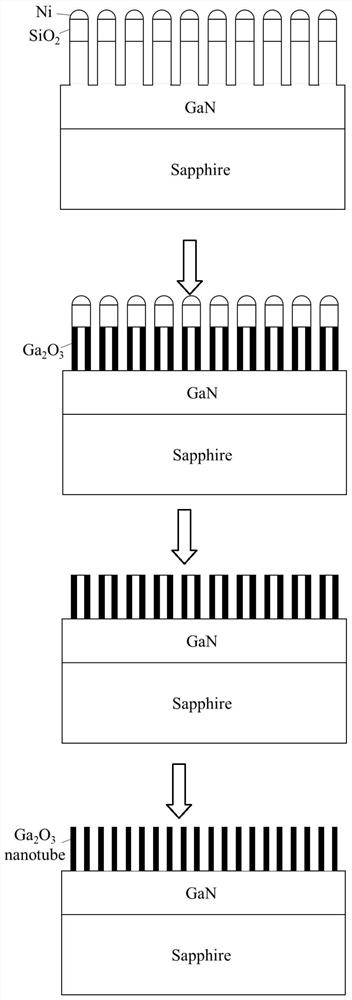

[0037] a vertical Ga 2 o 3 A method for preparing an ordered array of nanotubes, the steps comprising:

[0038] (1) The device is ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then dried with nitrogen, wherein the device is a GaN film grown on the substrate;

[0039] (2) Using plasma-enhanced chemical vapor deposition to grow a layer of SiO with a thickness of 200 nm on the cleaned device 2 Thin film, and then a layer of Ni metal film with a thickness of 20nm is deposited by electron beam evaporation;

[0040] (3) annealing the above metal-plated device to form a Ni metal nanoparticle structure used as an etching mask on the surface, the annealing temperature is 850 ° C, and the time is 10 min;

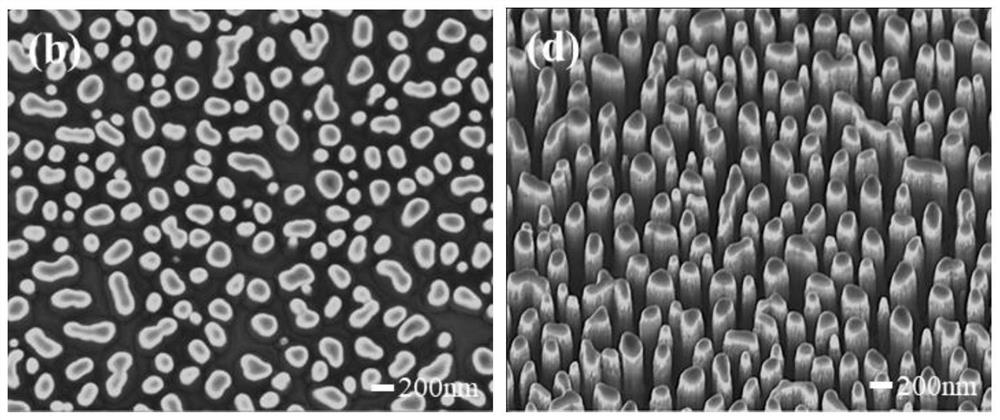

[0041] (4) Put the annealed device into RIE and ICP etching equipment sequentially, and use Ni metal nanoparticles as a mask to perform a dry etching process, wherein the RIE etching conditions: the etching gas is CF 4 / O 2 , the flow ratio is...

Embodiment 2

[0046] a vertical Ga 2 o 3 A method for preparing an ordered array of nanotubes, the steps comprising:

[0047] (1) The device is ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then dried with nitrogen, wherein the device is a GaN film grown on the substrate;

[0048] (2) on the device after cleaning, be the Ni metal thin film of 5nm by electron beam evaporation coating one deck thickness;

[0049] (3) annealing the above metal-coated device to form a Ni metal nanoparticle structure used as an etching mask on the surface, the annealing temperature is 750 ° C, and the time is 1 min;

[0050] (4) Put the annealed device into the ICP etching equipment and use Ni metal nanoparticles as a mask to perform a dry etching process. ICP etching conditions: the etching gas is Cl 2 / BCl 3 , the flow ratio is 24 / 6sccm, the etching power is 50 / 100W, the chamber pressure is 5mTorr, and the etching time is 4min to obtain an ordered array of vertical GaN ...

Embodiment 3

[0055] a vertical Ga 2 o 3 A method for preparing an ordered array of nanotubes, the steps comprising:

[0056] (1) The device is ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then dried with nitrogen, wherein the device is a GaN film grown on the substrate;

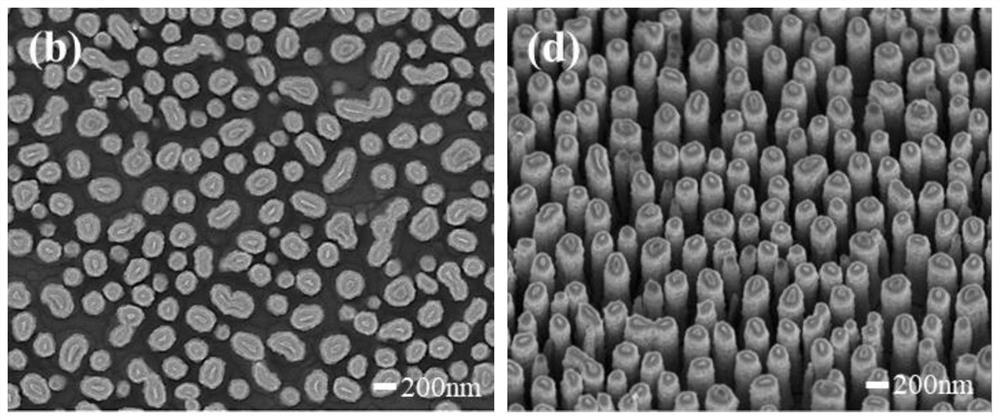

[0057] (2) Using plasma-enhanced chemical vapor deposition to grow a layer of SiO with a thickness of 400 nm on the cleaned device 2 Thin film, and then a layer of Ni metal film with a thickness of 50nm is deposited by electron beam evaporation;

[0058] (3) annealing the above metal-plated device to form a Ni metal nanoparticle structure used as an etching mask on the surface, the annealing temperature is 950 ° C, and the time is 20 min;

[0059] (4) Put the annealed device into RIE and ICP etching equipment sequentially, and use Ni metal nanoparticles as a mask to perform a dry etching process, wherein the RIE etching conditions: the etching gas is CF 4 / O 2 , the flow ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com