Derivative scaffold based on skin-derived acellular matrix and construction method ofderivative scaffold

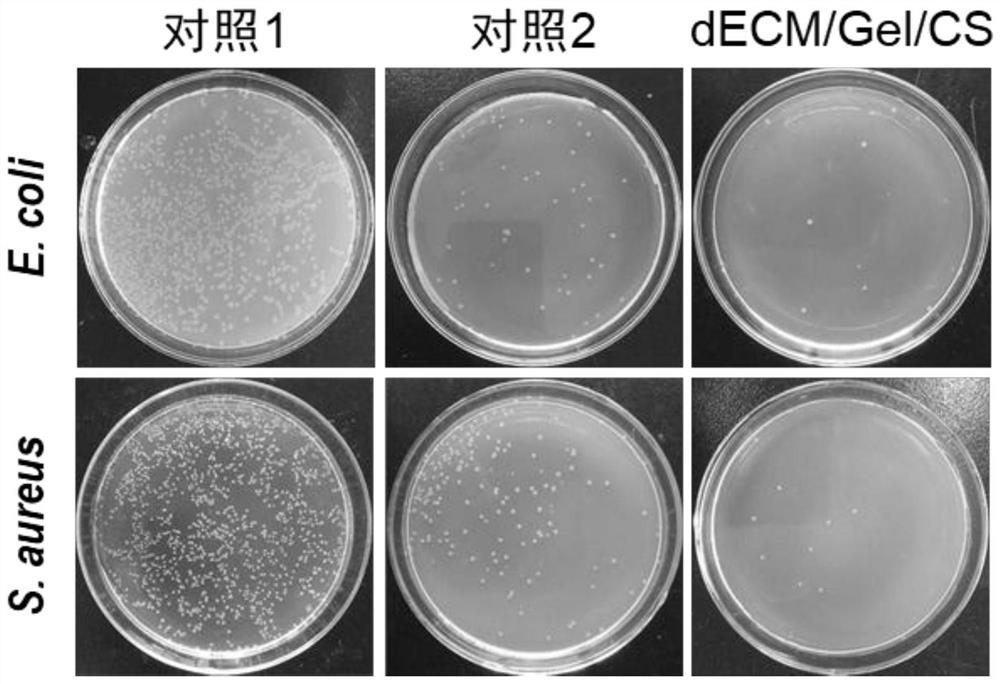

A technology of acellular matrix and construction method, which is applied in the field of tissue engineering scaffold and its construction, can solve the problems that have not been reported, and achieve the effect of improving mechanical strength, broad-spectrum antibacterial performance, and increasing cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

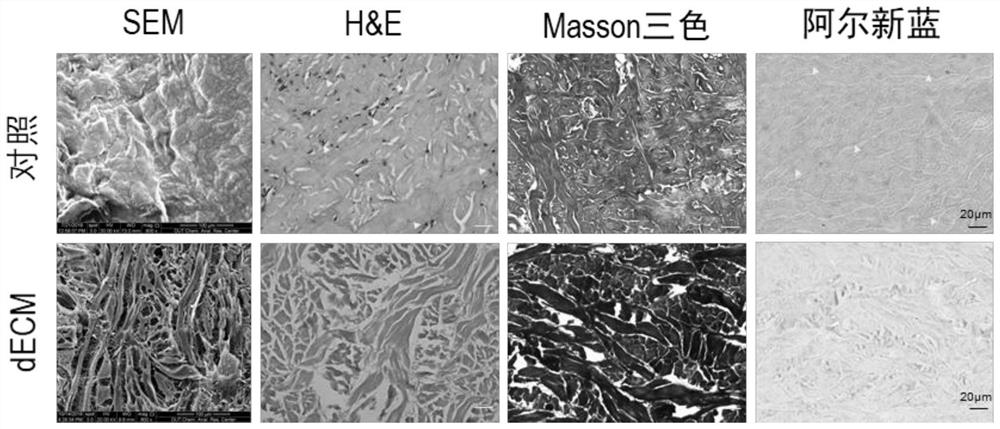

[0036] Example 1 Preparation of decellularized extracellular matrix scaffold (as a comparative example) and detection of decellularized efficiency

[0037] (1) Buy fresh pigskin from the market, wash it and cut it into 1.0cm 2 The small pieces were placed in a PBS solution containing 0.5wt% trypsin and 5mM ethylenediaminetetraacetic acid (EDTA), stirred in a water bath at 30°C for 8h for decellularization, and the stirring speed was 300rpm;

[0038] (2) Place the matrix obtained in step (1) in a PBS solution containing 5.0wt% Triton-X-100 and 20mM EDTA, stir at room temperature for 48h to decellularize, and the stirring speed is 300rpm;

[0039] (3) Place the matrix obtained in step (2) in an aqueous solution containing 20% isopropanol, and stir at room temperature for 24 hours to elute excess fat at a stirring speed of 300 rpm;

[0040] (4) Wash the matrix obtained by step (3) with PBS solution at room temperature for 3 times, each time at an interval of 1h, and wash with ...

Embodiment 2

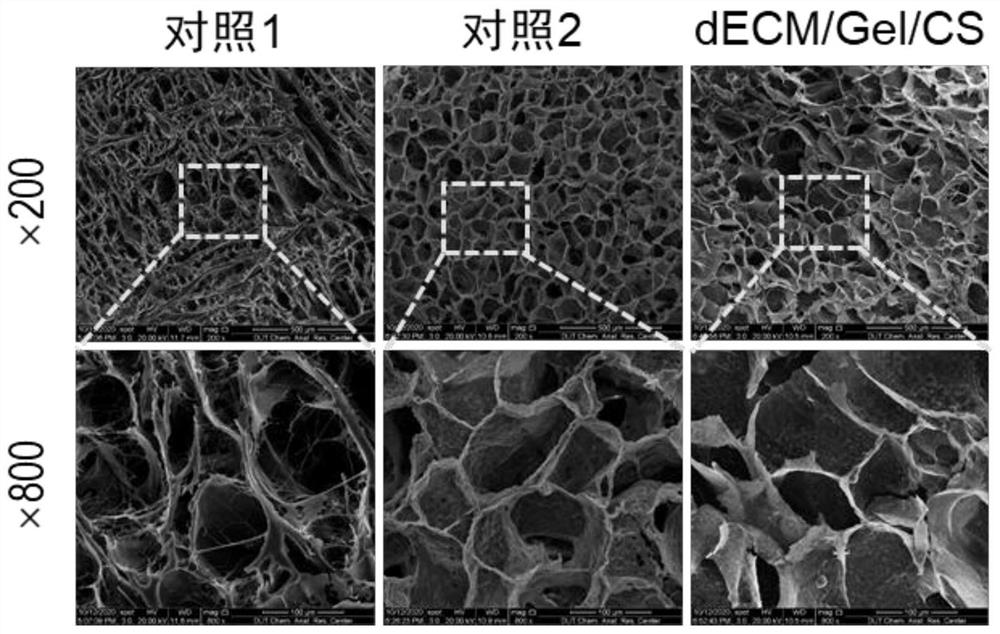

[0044] The preparation of embodiment 2 gelatin / chitosan (Gel / CS) composite support (as comparative example)

[0045] (1) Weigh 3 g of gelatin (Gel) and 1 g of chitosan (CS) into 100 mL of 0.5 mol / L acetic acid solution in turn, stir and dissolve under heating at 50°C.

[0046] (2) The Gel / CS solution in step (1) was slowly poured into a 24-well plate, frozen in a -20°C refrigerator for 12 hours, and then freeze-dried with a freeze dryer for 24 hours to obtain a porous composite scaffold.

[0047] (3) The composite scaffold in step (2) is cross-linked with a cross-linking agent for 24 hours at room temperature. The cross-linking agent is 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), N-hydroxysuccinimide (NHS), ethanesulfonic acid (MES ) and ethanol mixed solution. Among them, MES is used as the buffer solution of the cross-linking agent, the concentrations of EDC, NHS and MES are all 50mmol / L, and the volume fraction of the ethanol solution is 60%.

[00...

Embodiment 3

[0049] Example 3 Preparation of Decellularized Matrix / Gelatin / Chitosan (dECM / Gel / CS) Composite Scaffold

[0050] (1) Buy fresh pigskin from the market, wash it and cut it into 0.2cm 2 The small pieces of the mixture were placed in a PBS solution containing 0.1wt% trypsin and 1mM ethylenediaminetetraacetic acid (EDTA), stirred in a water bath at 10°C for 2h to decellularize, and the stirring speed was 100rpm;

[0051] (2) Place the matrix obtained in step (1) in a PBS solution containing 0.5wt% Triton-X-100 and 5mM EDTA, and stir at room temperature for 12h to decellularize, and the stirring speed is 100rpm;

[0052] (3) Place the substrate obtained in step (2) in an aqueous solution containing 5% isopropanol, stir for 12 hours at room temperature to elute excess fat, and the stirring speed is 100 rpm;

[0053] (4) Wash the substrate obtained in step (3) with PBS solution at room temperature for 3 to 4 times, with an interval of 1 hour each time, and wash with a solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com