Treatment method for selectively adsorbing and recycling precious metal ions in wastewater by using modified polymer adsorbent

A precious metal ion and treatment method technology, applied in the field of precious metal recovery, can solve the problems of low adsorption rate of adsorbent, can not be widely used, increase production cost, etc., achieve the effect of fast adsorption rate, strong load stability, and increase adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

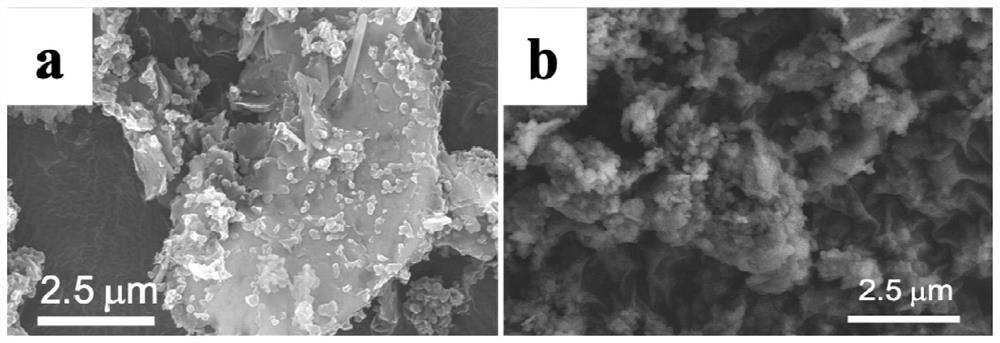

[0076] Preparation Example 1 A preparation method of a modified polymer adsorbent, comprising the steps of:

[0077] (1) Weigh 48.1mg of elemental sulfur, 145.6mg of terephthalic acid, 58.1mg of hexamethylenediamine and 24mg of activated carbon into a 20mL pressure-resistant tube, add 2mL of N,N-dimethylacetamide, add a magnetic rotor and stir for 12 minutes , placed in an ultrasonic instrument and ultrasonicated for 12 minutes to obtain a solid-liquid mixture;

[0078] (2) Vacuumize the solid-liquid mixture obtained in step (1) until there are no bubbles, fill it with nitrogen, and heat it to 100° C. to react for 15 hours to obtain a modified polymer mixture;

[0079] (3) Add 4 mL of N,N-dimethylformamide to the modified polymer mixture obtained in step (2), stir for 10 minutes, slowly add it dropwise to 100 mL of methanol, centrifuge for 5 minutes, remove the supernatant and collect Precipitate; then wash the precipitate with methanol, centrifuge again after washing for 5...

Embodiment 1

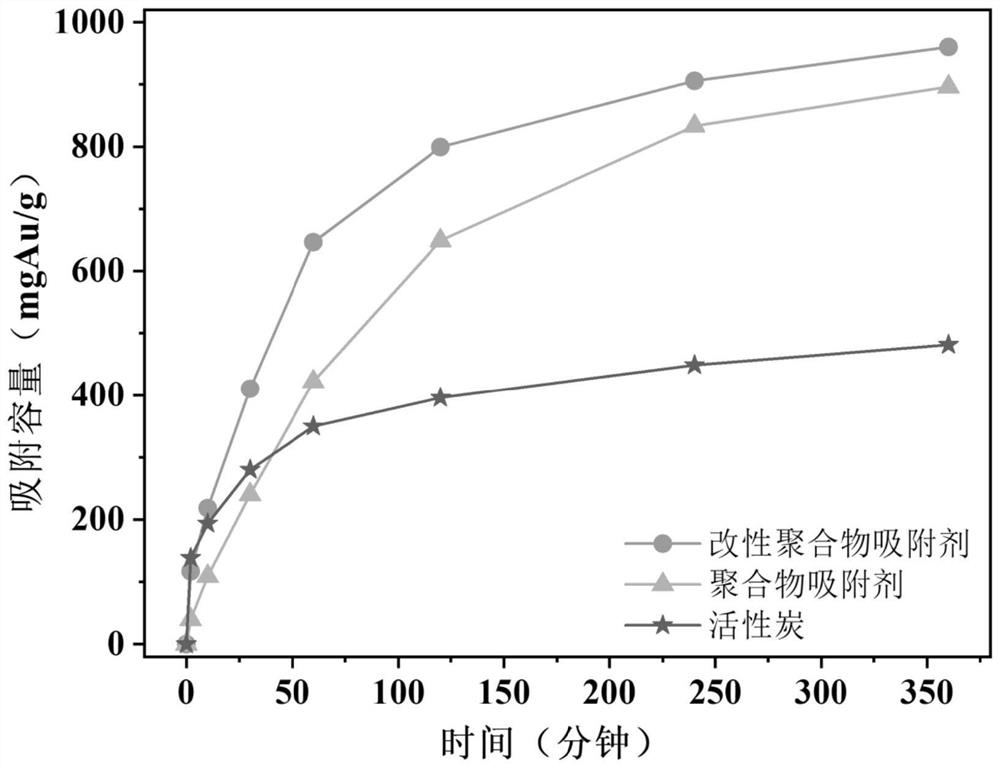

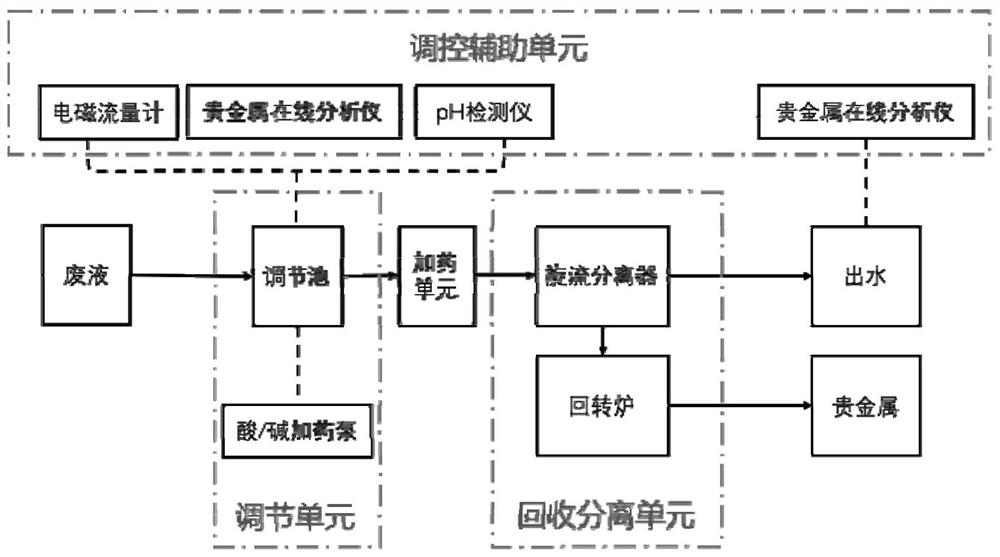

[0085] Example 1 A method for treating waste water utilizing a modified polymer adsorbent, comprising the steps of:

[0086] (1) Select the waste water of a certain type of waste CPU after dissolving N-bromosuccinimide and pyridine as the CPU waste water to be treated, and the metal dissolves into the solution in the form of ions (including gold, copper, nickel, cobalt, cadmium, cesium ,manganese);

[0087] (2) Send the CPU waste water into the adjustment pool, detect the pH of the incoming water through the pH detector, and feed back to the pH controller to control the automatic opening and closing of the acid / alkali dosing pump, thereby adjusting the pH value of the CPU waste water to 3.0. After the adjustment is completed CPU waste water enters the dosing unit;

[0088] (3) According to the concentration of the precious metals fed back by the influent water volume fed back by the electromagnetic flowmeter and the precious metals online analyzer, the dosage of the modifie...

preparation example 2

[0095] Preparation example 2A method for preparing a modified polymer adsorbent that selectively adsorbs and recovers precious metal ions, comprising the following steps:

[0096] (1) Weigh 481mg of elemental sulfur, 1750mg of piperazine, 1660mg of terephthalaldehyde and 200mg of polyurethane into a pressure-resistant tube, add 20mL of N,N-dimethylacetamide, add a magnetic rotor to stir for 12 minutes, and put it into an ultrasonic instrument Ultrasound for 12 minutes to obtain a solid-liquid mixture;

[0097] (2) Vacuumize the solid-liquid mixture obtained in step (1) until there are no bubbles, fill it with nitrogen, and heat it to 100° C. to react for 15 hours to obtain a modified polymer mixture;

[0098] (3) Slowly add the modified polymer mixture obtained in step (2) dropwise into 200mL methanol, centrifuge for 5 minutes, remove the supernatant to collect the precipitate; then wash the precipitate with methanol, and centrifuge again after washing Treat for 5 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com