Preparation method for oxide quantum dots loaded in flexible superfine porous carbon nanofiber

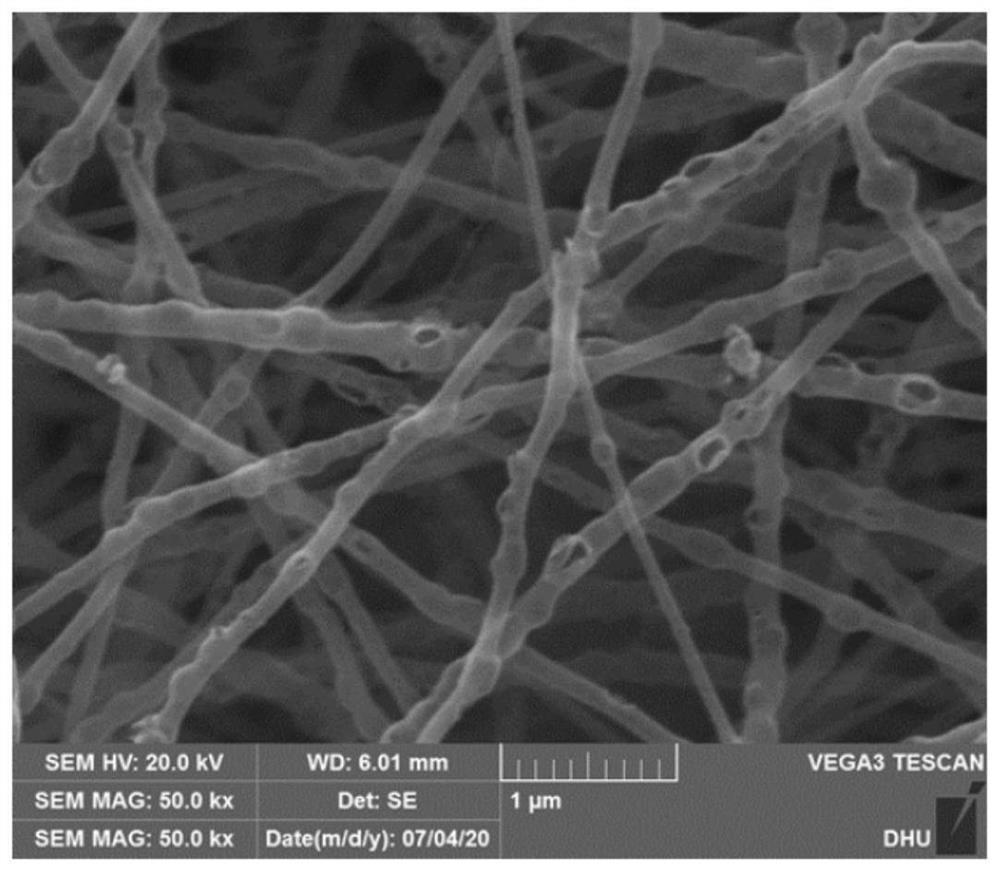

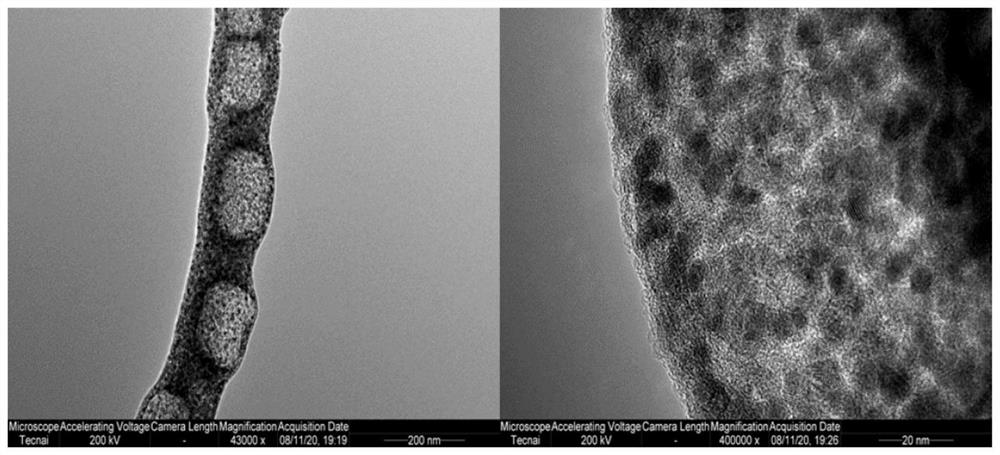

A technology of nanofibers and nanofiber membranes, applied in the fields of fiber chemical characteristics, fiber treatment, rayon manufacturing, etc., can solve the problems of brittleness of composite materials, complex synthesis process, low yield, etc., achieve small particle size, simple steps, The effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing flexible ultrafine porous carbon nanofiber-loaded zirconia quantum dots, the specific steps comprising:

[0031] (1) Configure a precursor solution consisting of polymer carbon source, solvent, pore-forming agent and metal salt: 0.9g polyvinylpyrrolidone (Aladdin, PVP, molecular weight 1300000) is dissolved in 5.1g distilled water at room temperature, Stir for 240min to configure a mass fraction of 10% polyvinylpyrrolidone solution, then add 0.01 mole of zirconium acetate (Aladdin) to the PVP solution, stir for 180min, and finally add 3g polytetrafluoroethylene emulsion (purchased from Dongguan Xingwang Plastic Co., Ltd. Raw material limited company, solid content 60%, particle size 0.2 μm), stirring to form a uniformly mixed precursor solution.

[0032] (2) Electrospinning the obtained precursor solution. Under the action of an electric field, the charge repulsion on the surface of the charged droplet exceeds its surface tension, forming a jet fr...

Embodiment 2

[0041] A method for preparing flexible ultrafine porous carbon nanofiber-loaded silicon oxide quantum dots, the specific steps comprising:

[0042] (1) Configure a precursor solution consisting of polymer carbon source, solvent, pore-forming agent and metal salt: 0.9g polyvinylpyrrolidone (Aladdin, PVP, molecular weight 1300000) is dissolved in 5.1g distilled water at room temperature, Stir for 240min to configure a polyvinylpyrrolidone solution with a mass fraction of 10%, then add 5g tetraethyl silicate (Aladdin) and 0.05g phosphoric acid (Aladdin) to the PVP solution, stir for 180min, and finally add 3g polytetrafluoroethylene to the solution Vinyl fluoride emulsion (purchased from Dongguan Xingwang Plastic Raw Materials Co., Ltd., solid content 60%, particle size 0.2 μm), stirred to form a uniformly mixed precursor solution.

[0043] (2) Electrospinning the obtained precursor solution. Under the action of an electric field, the charge repulsion on the surface of the charge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com