Polyoxymethylene dimethyl ether product system composition analysis method

A technology for polyoxymethylene dimethyl ether and composition analysis, which is applied in the field of chemical analysis, can solve the problems that analysis and detection methods cannot meet the requirements of accurately analyzing the composition of PODE product systems, and achieve good linear correlation, meet the requirements of accurate detection, reduce The effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1.1 Reagents and instruments

[0061] Methanol, methyl formate, methylal, paraformaldehyde, and ethylene glycol diethyl ether are all chromatographically pure, PODE 2 、PODE 3 Pure product (GC≥99.5%) provided for Beijing Dongfanghongsheng Research Institute; Agilent 7890B gas chromatograph, FID detector; chromatographic column: Agilent HP-1, 30m×0.320mm×0.25μm; Agilent HP6890-5973 gas phase Chromatography-mass spectrometry.

[0062] 1.2 Experimental conditions

[0063] 1.2.1 Gas chromatography analysis conditions

[0064] Agilent HP-1 capillary column (30m×0.320mm×0.25μm); column temperature adopts temperature program: 40°C for 5.0min, 50°C / min to 250°C for 5.8min; vaporization chamber temperature: 280°C; carrier gas : nitrogen, flow rate 1.0mL / min; split injection, split ratio 100:1; FID detector: 300°C, hydrogen: 30mL / min, air: 400mL / min, makeup gas: 25mL / min; sampling method: Automatic sampling; injection volume: 0.3-0.5 μL.

[0065] 1.2.2 Working conditions of ...

Embodiment 2

[0073] Embodiment 2 result and discussion

[0074] 2.1 PODE n Qualitative analysis of synthetic products

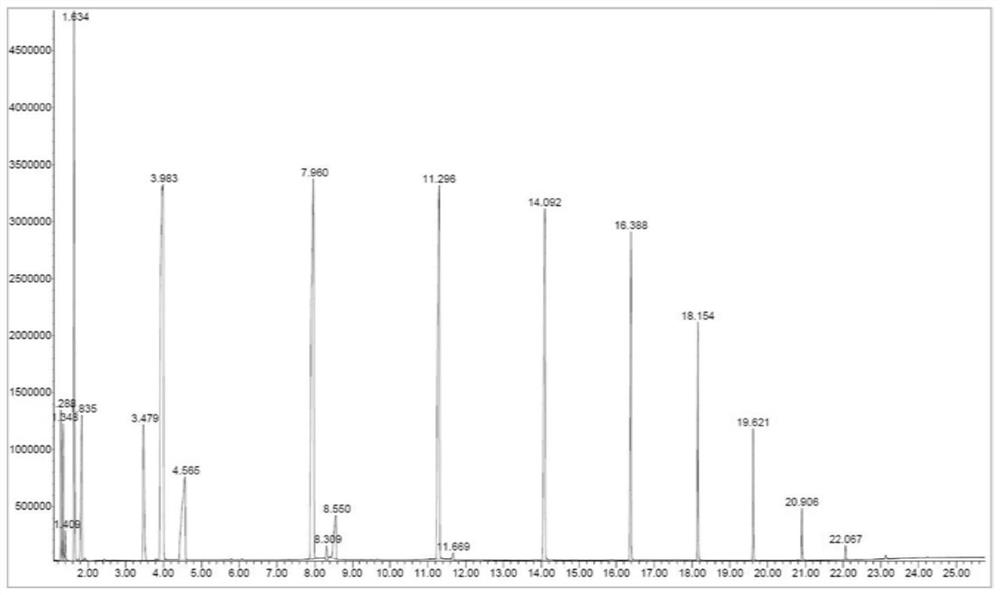

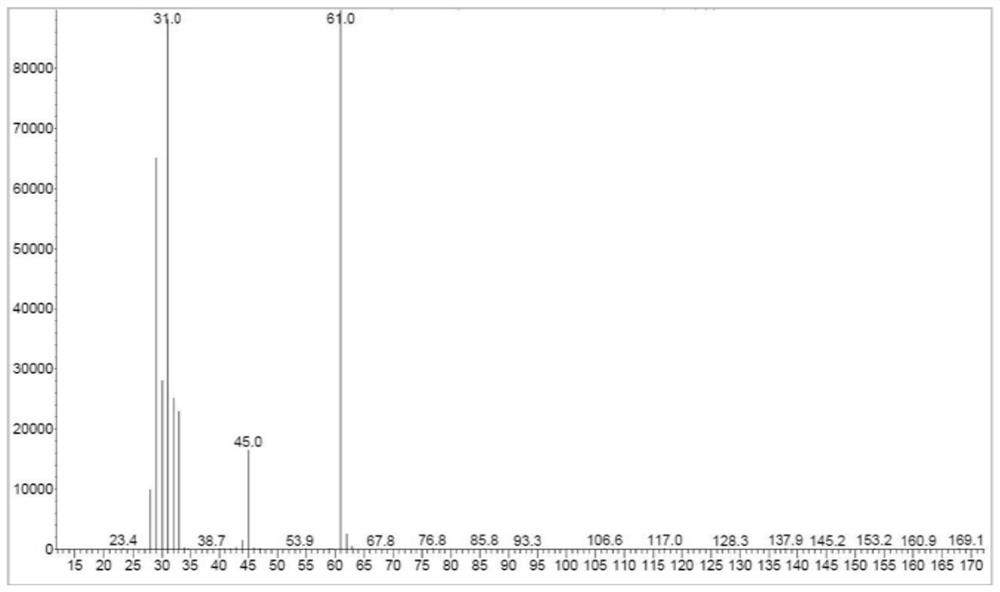

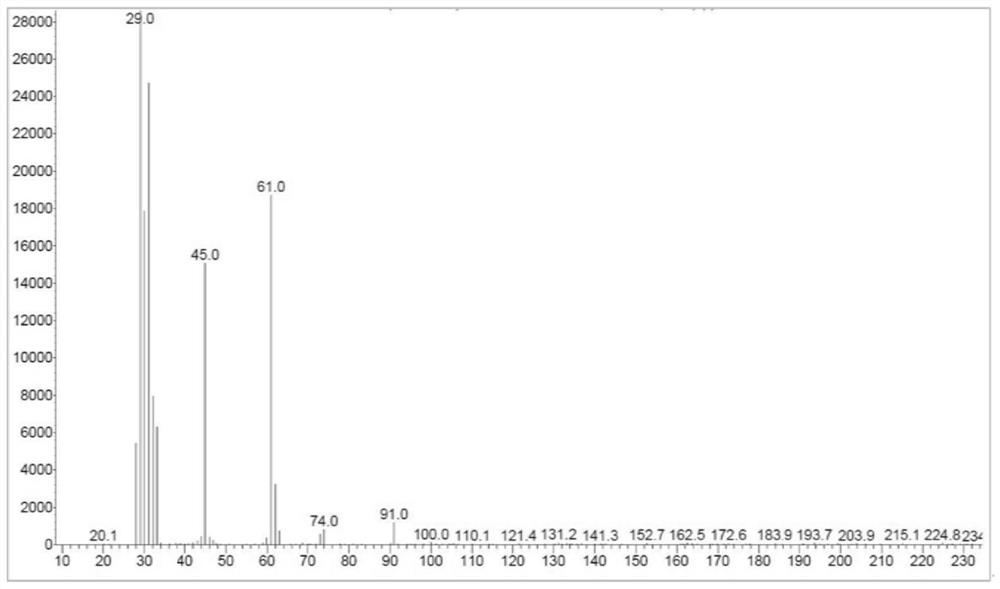

[0075] PODE n The qualitative analysis of each component in the synthetic product was mainly obtained by pure substance control and gas chromatography-mass spectrometry. like figure 1 Shown, for PODE n The gas chromatography-mass spectrogram of the synthesized product, for figure 1 The main components in the mass spectrogram analysis can determine the PODE n There are polymethoxy dimethyl ethers (PODE) with different degrees of polymerization in the product. 2-10 ), in addition, there are also unreacted raw materials and other impurity components in the product, such as DMM, TOX, HCHO, MeOH, MF, etc. Table 1 is PODE n Each component corresponds to the gas chromatography-mass spectrum retention time in the product, wherein the chromatographic peaks at 1.835min and 4.565min pass through possible reaction products and mass spectrograms (such as Figure 2-3 Shown) An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com