A kind of preparation method of lithium iron phosphate positive electrode of lithium ion battery

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of high temperature cycle and poor storage performance, to improve the degree of dispersion, improve discharge specific capacity and cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

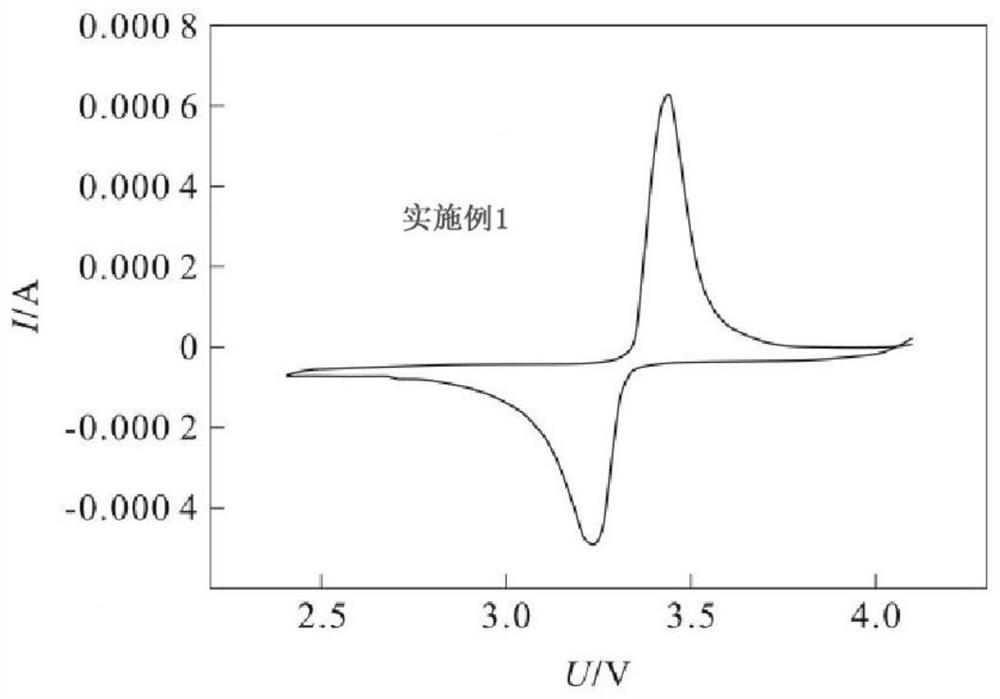

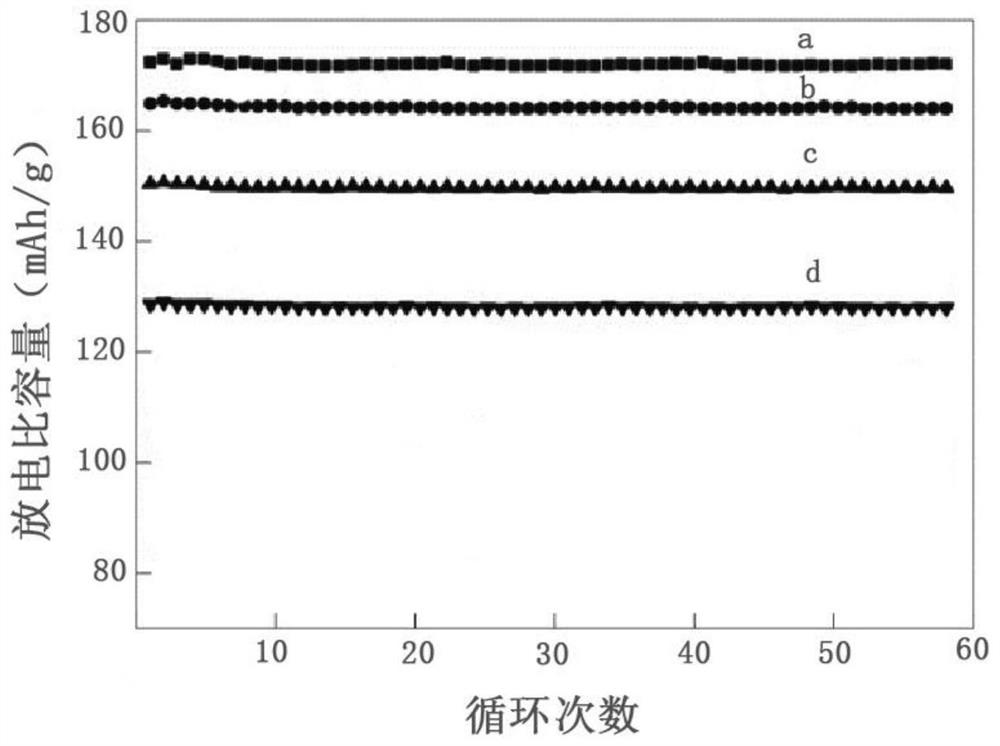

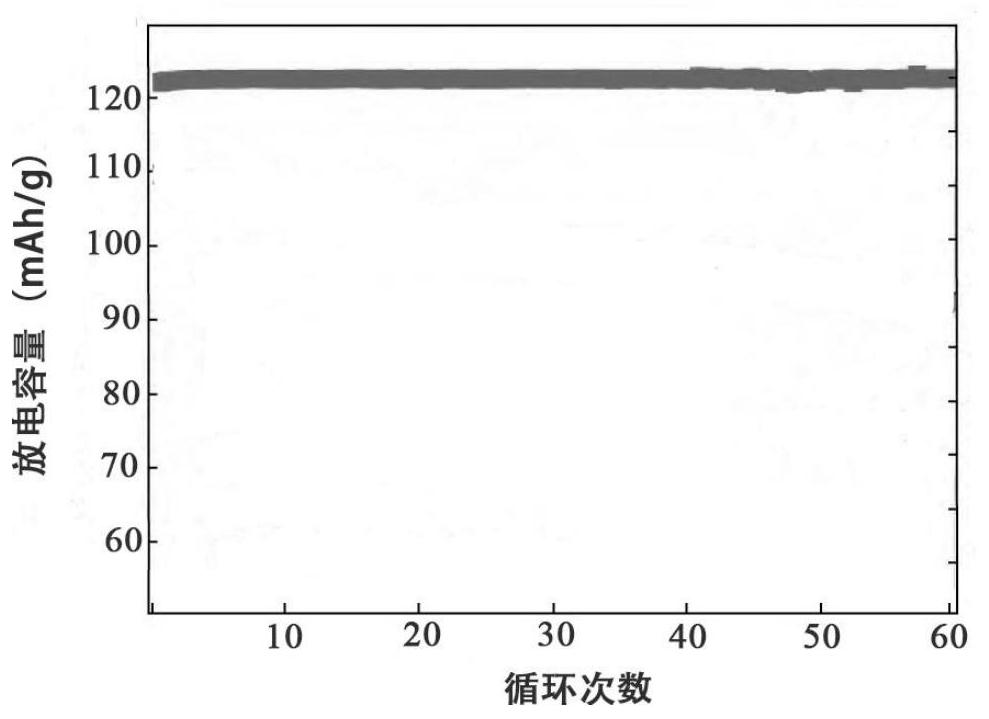

Embodiment 1

[0022] A preparation method of a lithium iron phosphate positive electrode of a lithium ion battery specifically comprises the following steps:

[0023] S1: Add polyferric chloride, lithium hydroxide, ammonium phosphate and citric acid in a mass ratio of 0.92:1:1.15:1.10 into distilled water and stir to dissolve, then dropwise add oxalic acid or ammonia water, stir and let stand for 10 hours for later use.

[0024] S2: Place the copper foil in a container filled with distilled water, take it out for drying after ultrasonication for 2 hours, then use 600-mesh sandpaper for grinding, place it in distilled water and anhydrous ethanol solution and ultrasonicate for 1 hour, respectively, and dry for use.

[0025] S3: The product in step S1 is moved to the electrospinning device, the spun silk is received on the copper foil in step S2, and a layer of lithium iron phosphate fiber film is obtained on the copper foil after spinning, and then placed on the copper foil. In a tube furnace...

Embodiment 2

[0027] A preparation method of a lithium iron phosphate positive electrode of a lithium ion battery specifically comprises the following steps:

[0028] S1: Add polymeric ferric sulfate, lithium carbonate, ammonium dihydrogen phosphate and glucose into distilled water according to the mass ratio of 1.08:1.22:1.36:1.56, stir and dissolve, then dropwise add oxalic acid or ammonia water, stir, and let stand for 15 hours for later use.

[0029] S2: place the copper foil in a container filled with distilled water, take it out for drying after sonicating for 3 hours, then use 800-mesh sandpaper for grinding, place it in distilled water and anhydrous ethanol solution for sonication for 2 hours respectively, and dry for use.

[0030] S3: The product in step S1 is moved to the electrospinning device, the spun silk is received on the copper foil in step S2, and a layer of lithium iron phosphate fiber film is obtained on the copper foil after spinning, and then placed on the copper foil. ...

Embodiment 3

[0032] A preparation method of a lithium iron phosphate positive electrode of a lithium ion battery specifically comprises the following steps:

[0033] S1: Add polyferric chloride, lithium acetate, diammonium hydrogen phosphate and citric acid into distilled water in a mass ratio of 0.96:1.06:1.21:1.19, stir and dissolve, then dropwise add oxalic acid or ammonia water, stir and let stand for 12 hours for later use.

[0034] S2: Place the copper foil in a container filled with distilled water, take it out and dry it after sonicating for 2.5 hours, then polish it with 700-grit sandpaper and place it in distilled water and anhydrous ethanol solution for 1.5 hours, respectively, and then dry it for later use. .

[0035] S3: The product in step S1 is moved to the electrospinning device, the spun silk is received on the copper foil in step S2, and a layer of lithium iron phosphate fiber film is obtained on the copper foil after spinning, and then placed on the copper foil. In a tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com