Preparation method of rapidly sintered porous ceramic

A porous ceramic and rapid sintering technology, which is applied in the field of porous ceramics, can solve problems such as body swelling and cracking, affecting the process of degreasing and debinding, sublimation, evaporation, cracking and detachment processes, etc., so as to improve the bending strength and reduce the firing process. Conditional requirements, effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Weigh 1000g particle size D 50 It is silicon carbide of 5 μm, and 85g of fully refined paraffin wax and 50g of aluminum dihydrogen phosphate are added to form a mixture;

[0026] Step 2: Heat the mixture obtained in Step 1 until the paraffin becomes liquid, mix it well with silicon carbide particles and aluminum dihydrogen phosphate, and then cool until the paraffin becomes solid, forming a block solid mixture; pass the block solid mixture through 60 mesh Sieve and granulate to obtain granulated powder;

[0027] Step 3: Fill the granulated powder obtained in Step 2 into the mold cavity, and press the dry powder with a pressure of 55kgf / cm 2 , body size 100mm×100mm×20mm;

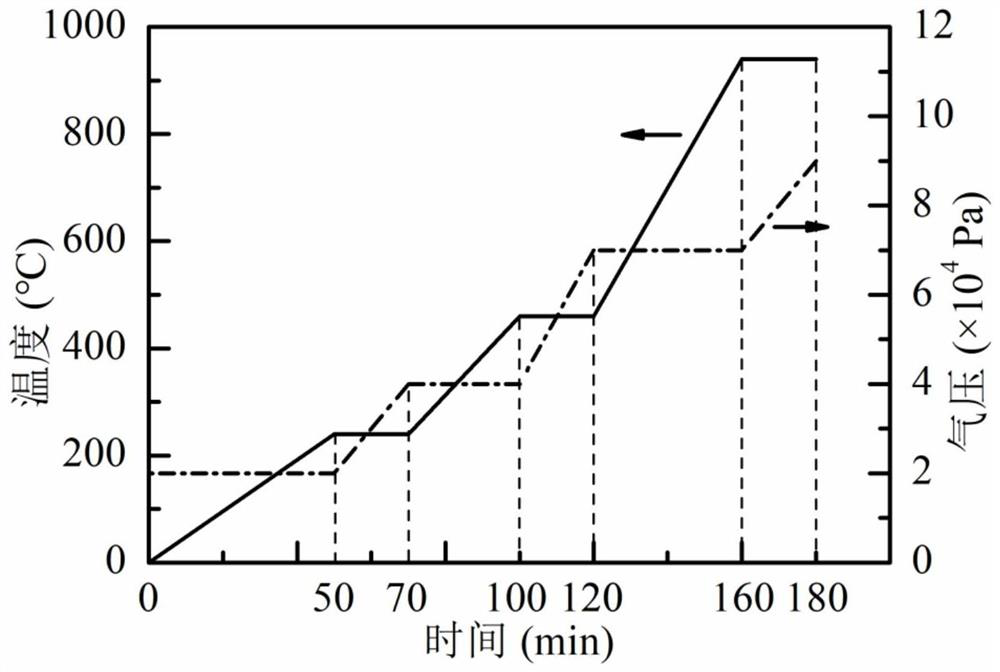

[0028] Step 4: Burn the green body gained in step 3, the temperature curve of the firing process (such as figure 1 Shown): from room temperature at a heating rate of 4.5°C / min, heating for 50 minutes to 240°C, and maintaining a constant temperature for 20 minutes; then at a heating rate of 1...

Embodiment 2

[0044] Step 1: Weigh 1000g particle size D 50 120 μm of corundum sand ceramic raw material, and add 350g polyvinyl alcohol (PVA) 1788 aqueous solution (its effective solid content is 10%), 65g boron glass powder (particle size is 20 μm), 50g polyethylene glycol (its effective solid content 20%), 10g lubricant (Luoyang Yefang YF-125, its effective solid content is 40%), forming a mixture;

[0045]Step 2: Add an appropriate amount of deionized water to the mixture obtained in Step 1, and stir it with a mixer until it is fully uniform to form a slurry; then place it in a resistance wire drying oven with a set temperature of 70°C, and dry it for 4 hours to form a solid mixture; The solid mixture is granulated with a 50-mesh sieve, and placed in a closed container for water homogenization treatment, and the water content is controlled within a range of 0.3% to 2.0%;

[0046] Step 3: Fill the granulated powder obtained in Step 2 into the mold cavity, and press the dry powder with a...

Embodiment 3

[0056] Step 1: Weigh 150g particle size D 50 100μm boron carbide (90% boron carbide content), 50g particle size D 50 20 μm boron carbide (boron carbide content is 90%), and add 31.58g propolis gum (effective solid content 38%), 8g aluminum dihydrogen phosphate (concentration 40%), 1.2g sodium citrate, form a mixture;

[0057] Step 2: Add an appropriate amount of distilled water to the mixture obtained in Step 1, stir it with a mixer until it is fully uniform, and then vacuumize it at a room temperature of 10 Pa for 60 minutes to form a slurry;

[0058] Step 3: Introduce the slurry obtained in Step 2 into the gypsum mold cavity for casting, demold and take the green body, dry the green body at 60-90°C for 5-7 hours, and the size of the green body

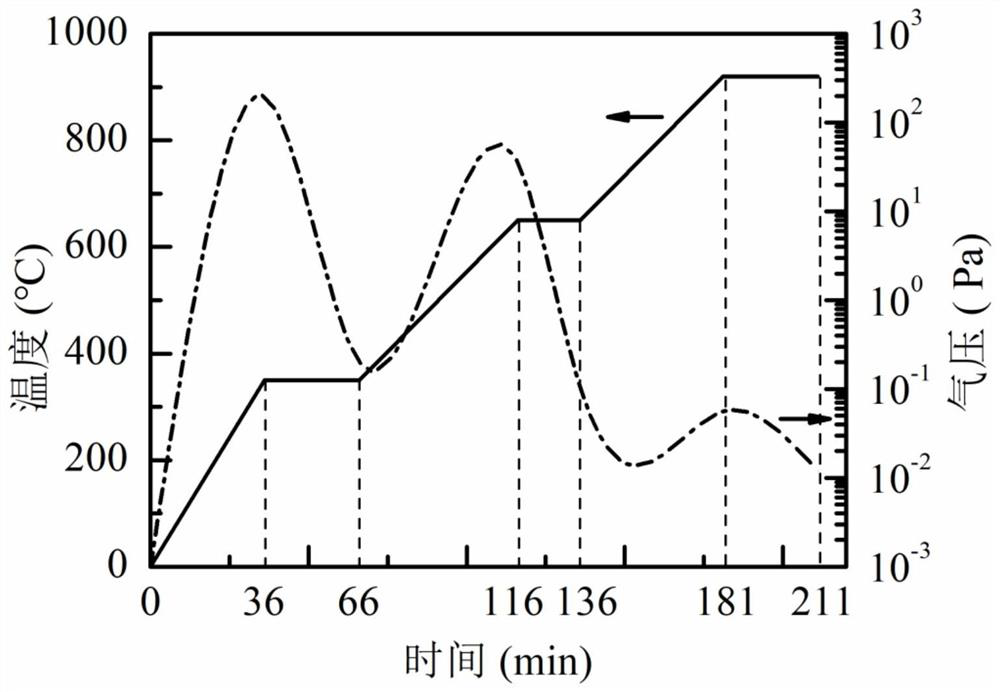

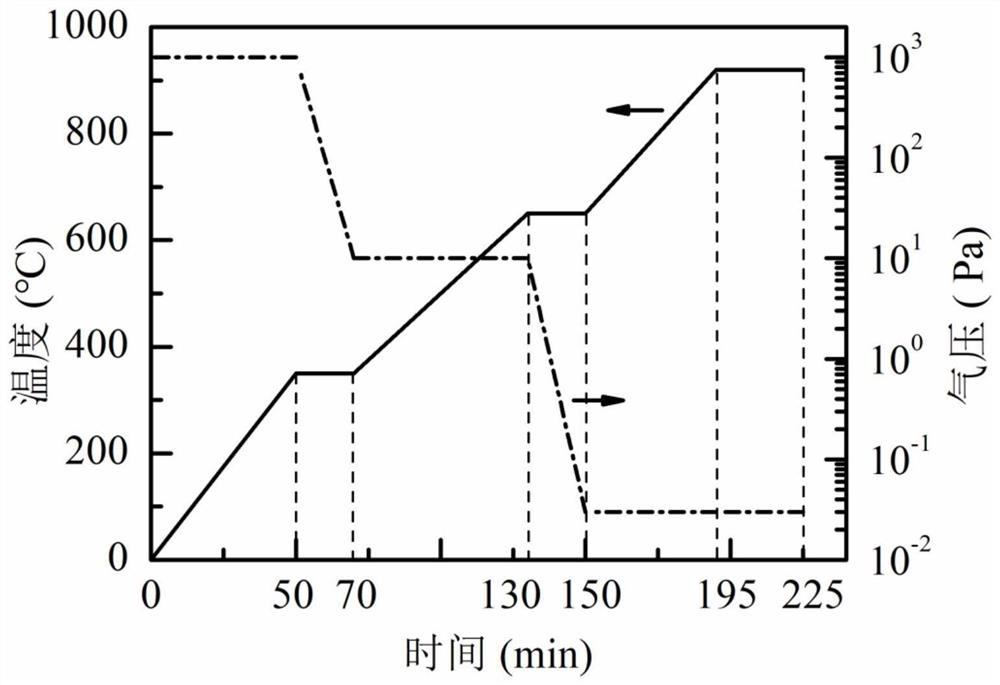

[0059] Step 4: Burn the green body obtained in Step 3, and use a vacuum furnace to fire, and the temperature curve of the firing process (such as figure 2 As shown): from room temperature at a heating rate of 10°C / min, heating f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com