Preparation method of quick-setting hot-melt marking coating

A marking paint, hot-melt technology, applied in fireproof paint, luminous paint, epoxy resin paint, etc., can solve the problems of not being able to warn at night, easy reunion of raw materials, short fluorescence quenching time, etc., to achieve Good performance, good thermal stability, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

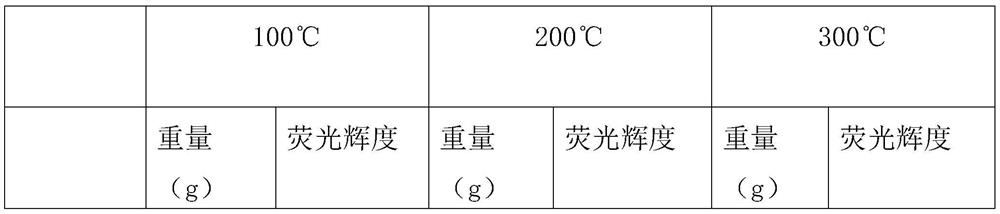

Examples

Embodiment 1

[0013] A preparation method of quick-setting hot-melt marking paint, prepared by the following steps: (1) methyl methacrylate, potassium persulfate, rare earth material and deionized water in N 2 At 65°C, stir for 1 h at a rate of 30rmp / min, centrifuge, filter, take the precipitate, and dry to prepare polymethyl methacrylate nanospheres with fluorescent properties; (2) nano-TiO 2 Mix with rare earth material deionized water, add porous calcium carbonate microspheres, ultrasonic 20min, then add disodium edetate solution, stir for 20min, dry; (3) add benzoyl peroxide, step (1) The prepared polymethyl methacrylate nanospheres, polypropylene, pearl powder, nano-silica, hollow porous glass microspheres, polypropylene, pearl powder, isocyanate, ethylene-vinyl acetate copolymer, polyvinyl chloride, epoxy Resin, rare earth material, silane coupling agent, polydimethylsiloxane, antifoaming agent, mixed, used, it is used after heating.

[0014] The mass volume ratio of methyl methacryl...

Embodiment 2

[0022] A preparation method of quick-setting hot-melt marking paint, prepared by the following steps: (1) methyl methacrylate, potassium persulfate, rare earth material and deionized water in N 2 Stir at 70°C for 1.5h at a rate of 35rmp / min, centrifuge, filter, take the precipitate, and dry to obtain polymethyl methacrylate nanospheres with fluorescent properties; (2) Nano TiO 2 Mix it with rare earth material deionized water, add porous calcium carbonate microspheres, ultrasonicate for 25 minutes, then add disodium edetate solution, stir for 25 minutes, and dry; (3) add benzoyl peroxide, step (1) The prepared polymethyl methacrylate nanospheres, polypropylene, pearl powder, nano-silica, hollow porous glass microspheres, polypropylene, pearl powder, isocyanate, ethylene-vinyl acetate copolymer, polyvinyl chloride, epoxy Resin, rare earth material, silane coupling agent, polydimethylsiloxane, antifoaming agent, mixed, used, it is used after heating.

[0023] The mass volume ra...

Embodiment 3

[0031] A preparation method of quick-setting hot-melt marking paint, prepared by the following steps: (1) methyl methacrylate, potassium persulfate, rare earth material and deionized water in N 2 At 75°C, stir for 2h at a rate of 45rmp / min, centrifuge, filter, take the precipitate, and dry to prepare polymethyl methacrylate nanospheres with fluorescent properties; (2) nano-TiO 2 Mix with rare earth material deionized water, add porous calcium carbonate microspheres, ultrasonic 20-30min, then add disodium edetate solution, stir for 30min, and dry; (3) add benzoyl peroxide, step ( 1) The prepared polymethyl methacrylate nanospheres, polypropylene, pearl powder, nano silicon dioxide, hollow porous glass microspheres, polypropylene, pearl powder, isocyanate, ethylene-vinyl acetate copolymer, polyvinyl chloride, Epoxy resin, rare earth material, silane coupling agent, polydimethylsiloxane, antifoaming agent, mixed and used, use it after heating.

[0032] The mass volume ratio of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of retroreflection | aaaaa | aaaaa |

| Coefficient of retroreflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com