Polymer microsphere and preparation and application thereof

A technology of polymers and microspheres, which is applied in the preparation methods of peptides, alkali metal compounds, biochemical equipment and methods, etc., can solve problems such as difficulty in expression, large molecular weight of Protein A, and limited processing capacity of chromatographic operations, so as to solve the problem of formulating Expensive base, simple operation, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

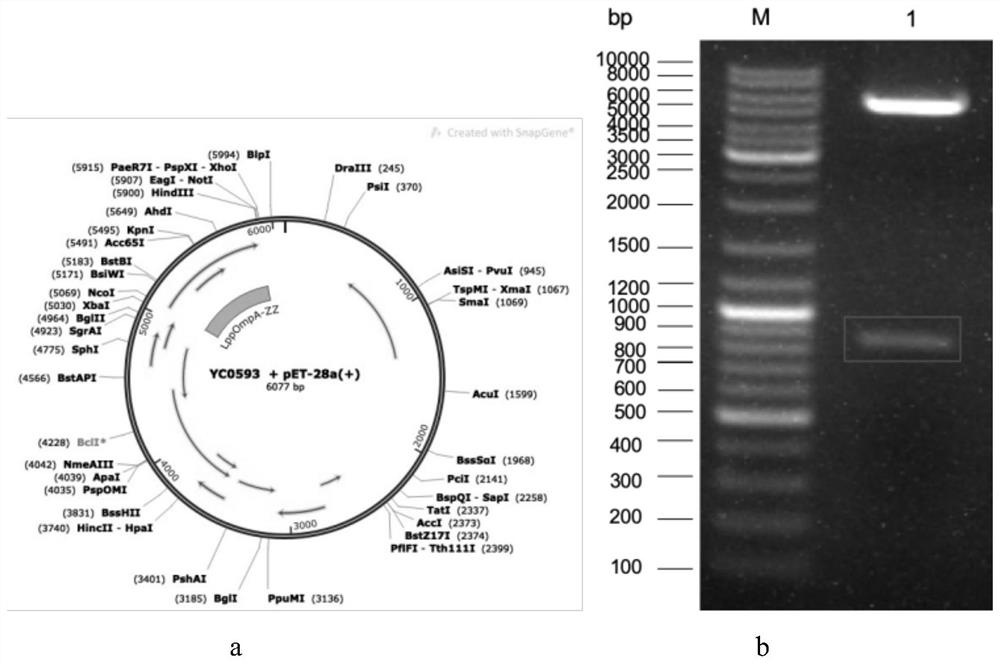

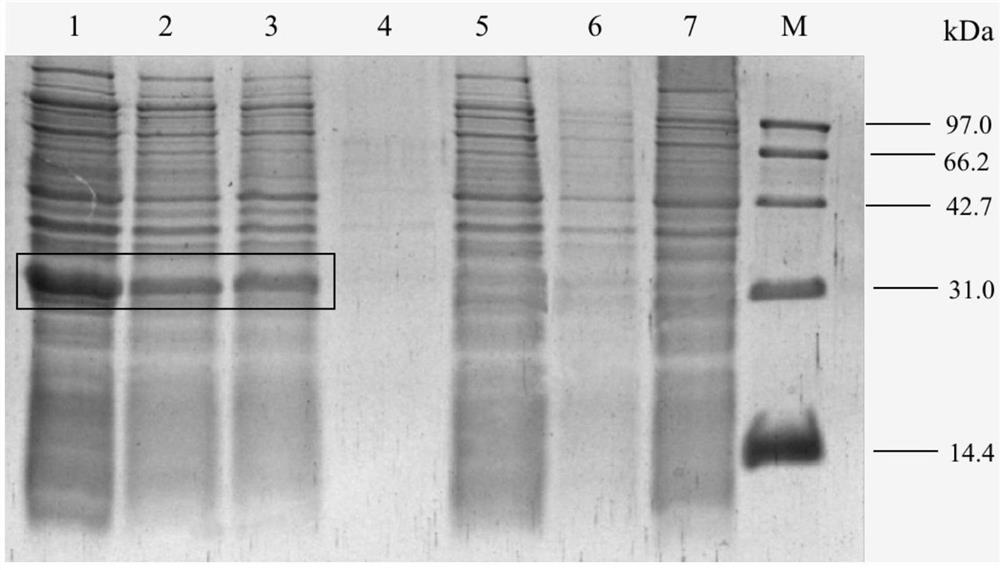

[0035] Construction and induced expression of embodiment 1 recombinant strain

[0036] 1. Construction of recombinant strains

[0037] The amino acid sequence of the ZZ domain is (SEQ ID NO.1):

[0038] RQHDEAVDNKFNKEQQNAFYEILHLPNLNEEQRNAFIQSLKDDPSQSANLLAEAKKLNDAQAPKVDNKFNKEQQNAFYEILHLPNLNEEQRNAFIQSLKDDPSQSANLLAEAKKLNDAQAPKVDAN.

[0039] The amino acid sequence of the peptide connecting the ZZ domain and the LppOmpA protein is: GIPG.

[0040] Ankyrin (LppOmpA) amino acid sequence is (SEQ ID NO.3):

[0041] MKATKLVLGAVILGSTLLAGCSSNAKIDQGINPYVGFEMGYD7WLGRMPYKGSVENGAYKAQGVQLTAKLGYPITDDLDIYTRLGGMVWRADTKSNVYGKNHDTGVSPVFAGGVEYAITPEIATRLEYQWTNNIGDAHTIGTRPDN.

[0042] (1) pET28a-LppOmpA-ZZ plasmid

[0043] According to the coding sequence of the ZZ domain gene (AAB00807.1, nucleotide sequence such as SEQ ID NO.2), it is fused with the anchor protein (LppOmpA) through the connecting peptide (GIPG) and provided by Sangon Bioengineering (Shanghai) Co., Ltd. The company carried out c...

Embodiment 2

[0057] Embodiment 2, preparation and characterization of polymer microspheres

[0058] (1) Add 0.6g of polyvinyl alcohol particles (PVA1799 type), 0.1g of sodium alginate (SA) powder and 9.3mL of double distilled water into a 25ml eggplant-shaped bottle, and stir at 95°C until the solution is clear and transparent to obtain PVA / SA mixed solution (wherein PVA mass concentration 6.0wt%, SA mass concentration 1.0wt%); Add the recombinant bacteria E.coli BL21 (DE3) / pET-28a-LppOmpA-ZZ bacterium that embodiment 1 prepares after being cooled to 40 ℃ 0.5ml solution (wet cell content: 5.8mg / mL), stirred evenly at room temperature (20-25°C) for 30min to obtain 10.5mL cell mixture solution as the water phase.

[0059] (2) In a 100mL round bottom flask, add 20ml liquid paraffin, 1.5ml Span 80 as a surfactant, mechanically stir at a speed of 300r / min for 30min, then use it as the oil phase, slowly add 20.0mL of the water phase prepared in step (1) drop by drop , stirred in a water bath a...

Embodiment 3

[0062] Embodiment 3, performance and application of polymer microsphere

[0063] 1. The binding properties of polymer microspheres:

[0064] The polymer microspheres prepared in Example 2 were washed three times with Tris-HCl buffer solution with pH=7.2, 0.02mol / L, 0.1g was put into a 1.5mL centrifuge tube, and 0.5mL was added with pH=7.2, 0.02mol / L FITC-labeled rabbit anti-mouse IgG solution (H+L, purchased from Sangon Bioengineering (Shanghai) Co., Ltd.) with a concentration of 0.2 mg / mL prepared in Tris-HCl buffer solution, and incubated in a 25°C incubator After 3 hours, they were quickly washed 2-3 times with Tris-HCl buffer solution of pH = 7.2 and 0.02 mol / L, and then examined by fluorescence microscope as the experimental group.

[0065] Under the same conditions, no FITC-IgG antibody solution was used as the control group. The polymer microspheres were replaced by the control polymer microspheres of Example 2 as a blank control group.

[0066] The results of fluore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com