Hollow microsphere core-shell catalyst as well as preparation method and application thereof

A technology of core-shell catalysts and hollow microspheres, applied in catalyst activation/preparation, catalyst carriers, molecular sieve catalysts, etc., can solve the problems of low catalytic efficiency, low economic benefits, and low catalyst sublimation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Prepare a 1mol / L glucose solution, take 70mL of the solution after it is completely dissolved, place it in a 100mL tetrafluoroethylene-lined reactor, conduct a hydrothermal reaction at 180°C for 8 hours, and cool the reactor to room temperature to obtain Brown product - carbon globules. The obtained product was alternately washed four times with absolute ethanol and deionized water, dried at 80° C. for 5 h, and then reserved for use.

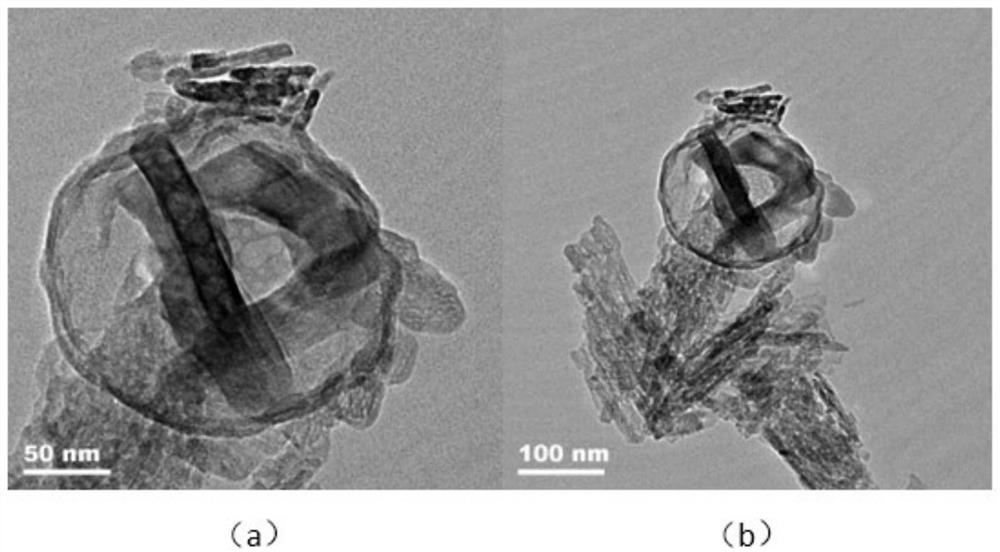

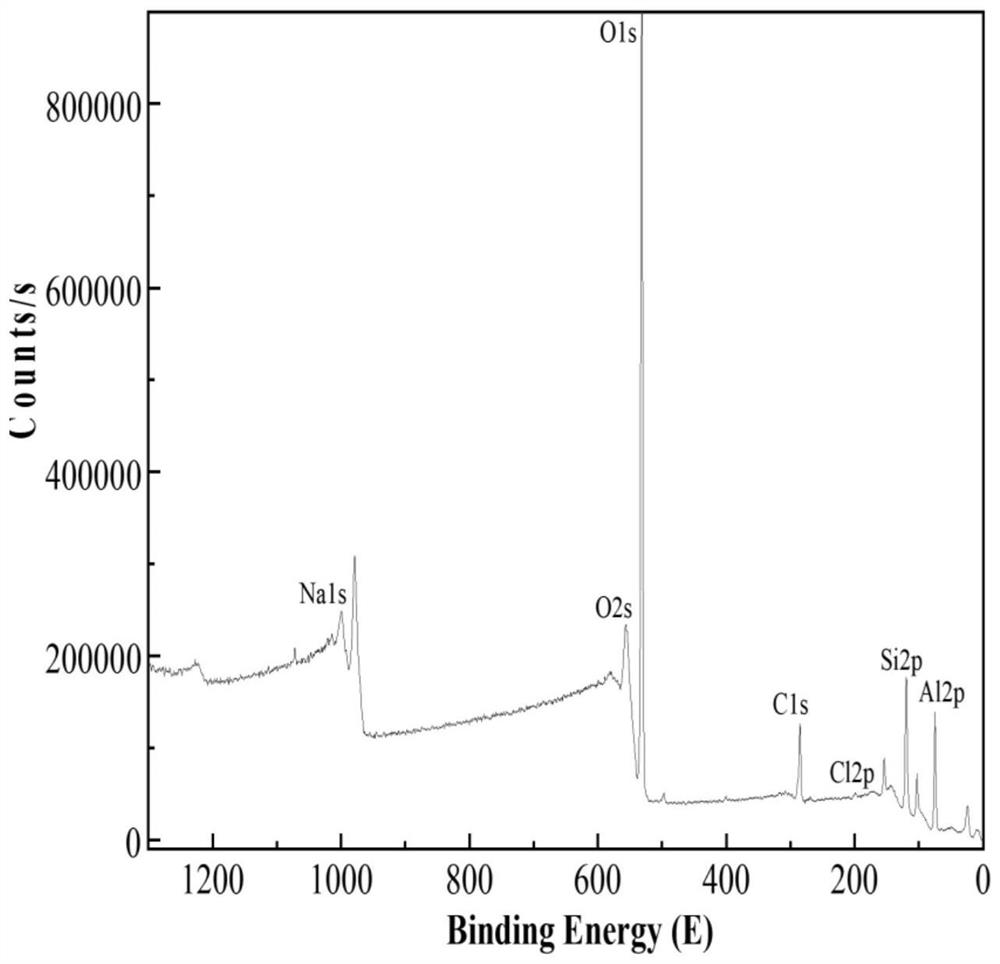

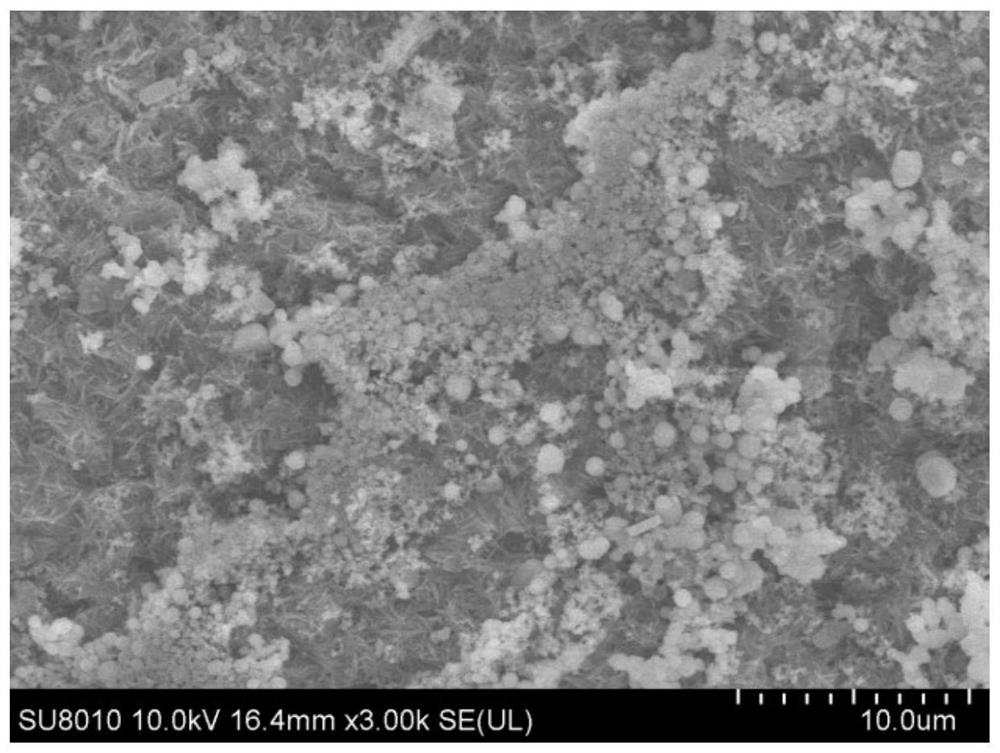

[0043] (2) Weigh 15g Al(NO 3 ) 3 9H 2 O, add dehydrated alcohol, it is mixed with the aluminum nitrate ethanolic solution of 0.4mol / L. Take 60mL of this solution, add 0.2g of carbon pellets, stir for 1h, and let it fully dissolve. Then pour it into a reaction kettle lined with tetrafluoroethylene, conduct a hydrothermal reaction at 180°C for 6 hours, and cool to room temperature to obtain a black precipitate. After filtering, washing, and drying in an oven at 80°C for 5 hours, Al 2 o 3 A product of @C. Al again 2 o 3 @C is t...

Embodiment 2

[0049] The difference with Example 1 is:

[0050] In step (3), according to Al 2 o 3 :TPAOH:TEOS:H 2 The molar ratio of O=0.5:9:25:480 (Si / Al ratio is 50) prepares the ZSM-5 precursor solution to obtain γ-Al with Si:Al=50 2 o 3 @ZSM-5 hollow microsphere carrier;

[0051] In step (4), in AlCl 3 The immersion time in the solution is 4h, and the load of double salt is 8wt%.

[0052] Connect the reaction instrument with the gas chromatograph, use the gas chromatograph sampling chamber, vaporize the reactant and enter the reaction kettle, and the reacted product enters the chromatogram for detection and analysis along with the carrier; prepare monomethyltrichlorosilane and trichlorosilane Methyl monochlorosilane volume ratio is the reaction solution of 1:2, the NaAlCl of 0.5g 4 / γ-Al 2 o 3 @ZSM-5 hollow microsphere core-shell catalyst is placed in a single-stage high-temperature furnace reaction tube, the reaction temperature of the high-temperature furnace is adjusted, an...

Embodiment 3

[0055] The difference with Example 1 is:

[0056] In step (3), according to Al 2 o 3 :TPAOH:TEOS:H 2 O=0.333:9:25:480 (Si / Al ratio is 75) to prepare ZSM-5 precursor solution to obtain γ-Al with Si:Al=75 2 o 3 @ZSM-5 hollow microsphere carrier;

[0057] In step (4), in AlCl 3 The immersion time in the solution is 3 hours, and the loading amount of the double salt is 12wt%.

[0058] Connect the reaction instrument with the gas chromatograph, use the gas chromatograph sampling chamber, vaporize the reactant and enter the reaction kettle, and the reacted product enters the chromatogram for detection and analysis along with the carrier; prepare monomethyltrichlorosilane and trichlorosilane Methyl monochlorosilane volume ratio is 1:2 reaction liquid, the NaAlCl of 0.7g 4 / γ-Al 2 o 3 @ZSM-5 hollow microsphere core-shell catalyst is placed in a single-stage high-temperature furnace reaction tube, the reaction temperature of the high-temperature furnace is adjusted, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com