Bipolar plate of water electrolysis hydrogen production system as well as preparation method and application thereof

A hydrogen production system and water electrolysis technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor electrical conductivity and low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a bipolar plate of a water electrolysis hydrogen production system, comprising the following steps:

[0041] S1: preparing a porous titanium substrate;

[0042] Further, step S1 specifically includes:

[0043] S101: Ball milling titanium dioxide powder: disperse titanium dioxide powder in a solvent, and then use zirconia in a polyethylene tank for ball milling for 2 to 2.5 hours to decompose titanium dioxide powder and avoid agglomerates affecting the performance of the material to obtain a slurry; The average particle size of titanium dioxide powder is 0.2-0.3μm, and the specific surface area is 9m 2 / g;

[0044] S102: adding a preset ratio of binder and plasticizer to the slurry, and forming it by tape casting;

[0045] Further, after adding a preset proportion of binder to the slurry for grinding, then adding the same proportion of plasticizer for grinding, and then casting the ground mixture on the organi...

Embodiment 1

[0055] The preparation process of the porous substrate is as follows:

[0056] S1. Get 64g titanium dioxide powder and be dispersed in the azeotropic liquid that toluene and ethanol volume ratio are 1:1, then grind 2 hours with zirconia ball in polyethylene tank;

[0057] S2. Add 18 g of polyvinyl butyral to the slurry ground in step S1 and grind for 24 hours, then add 18 g of polyethylene glycol and mix for another 24 hours;

[0058] S3. Cast the mixture ground in step S2 on the polyester film at a speed of 30 cm / min by tape casting method, and control the thickness of one-time molding at 0.4 mm, and repeatedly pour 3 times in the equipment;

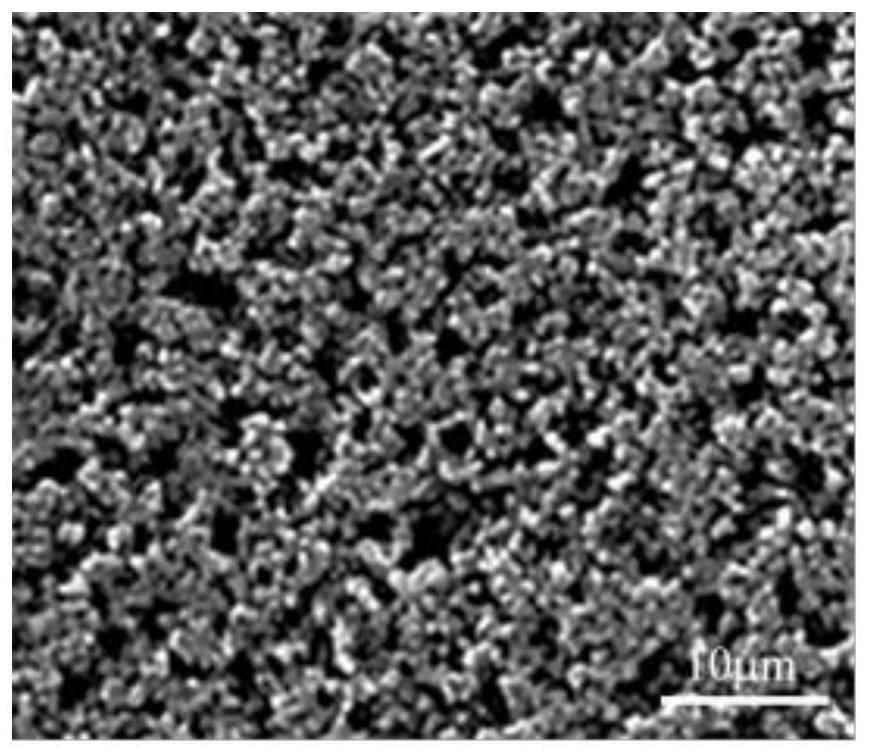

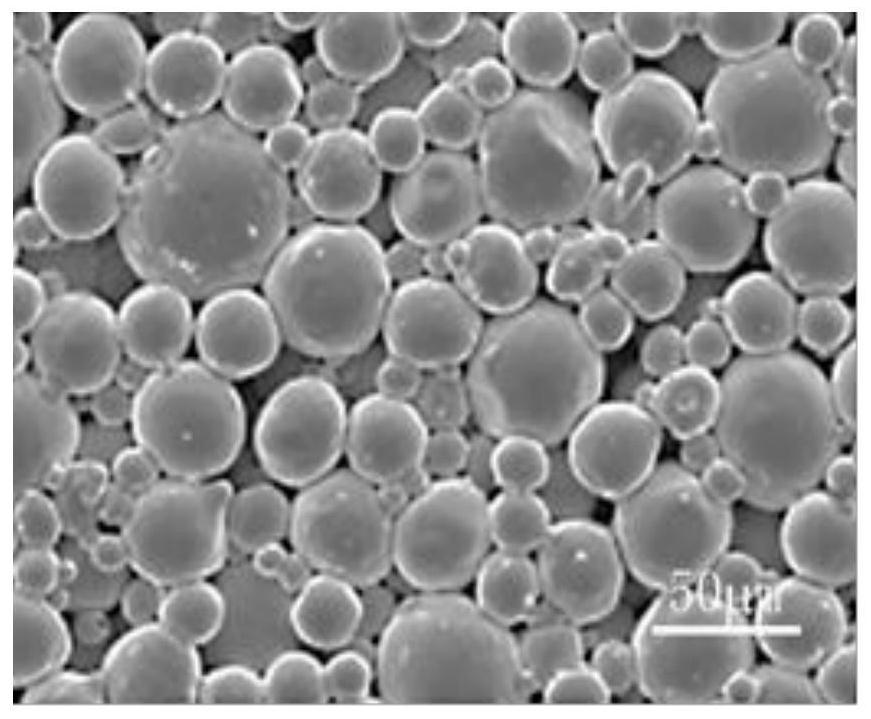

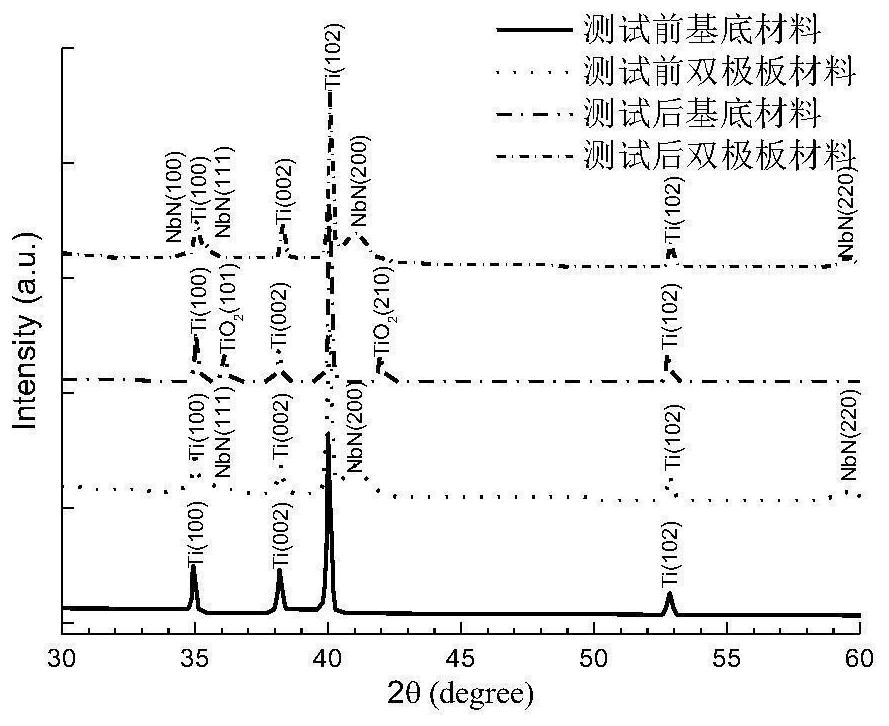

[0059] S4. Heating the poured sample at a rate of 2.5°C / min to 500°C for 2 hours to remove organic reagents, and then raising the temperature to 700°C at a rate of 5°C / min and keeping it for 3h to obtain the desired porous titanium substrate. A scanning electron microscope was used to observe the topography of the substrate surface, su...

Embodiment 2

[0069] The preparation process of the porous substrate is as follows:

[0070] S1. Get 76g of titanium dioxide powder and be dispersed in the azeotropic liquid that the volume ratio of toluene and ethanol is 1:1, then grind 2.5 hours with zirconia balls in polyethylene tank;

[0071] S2. Add 12 g of polyvinyl butyral to the ground slurry in step S1 and grind for 24 hours, then add 12 g of polyethylene glycol and mix for another 24 hours;

[0072] S3. Cast the mixture ground in step S2 on the polyester film at a speed of 35 cm / min by tape casting method, and control the thickness of one-time molding at 0.4 mm, and repeatedly pour 3 times in the equipment;

[0073] S4. Heating the poured sample at a rate of 2.5 °C / min for 2 hours to about 500 °C to remove the organic reagent, then raising the temperature to 900 °C at a rate of 6 °C / min and keeping it for 1 hour to obtain the desired porous titanium substrate. The morphology of the substrate surface was observed by scanning elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com