Polymer cholesteric liquid crystal laser and production method thereof, and optical equipment

A cholesteric liquid crystal and laser technology, applied in the field of lasers, can solve the problems of high laser threshold, low device repeatability, low emission intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

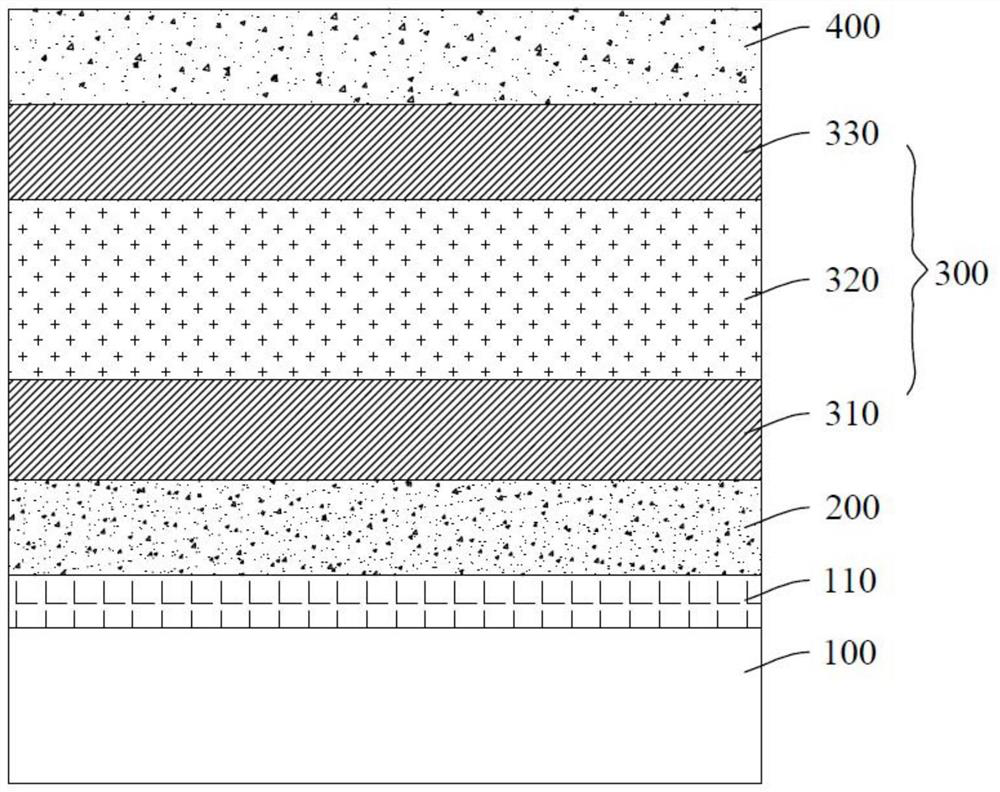

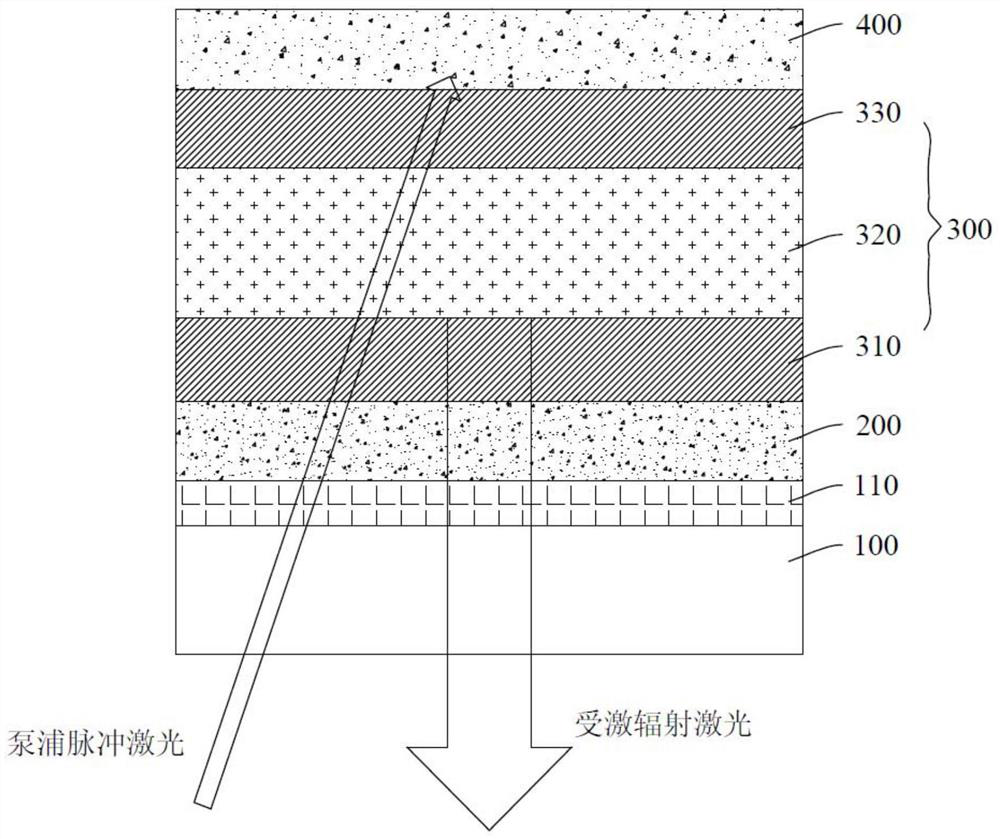

[0030] In this embodiment, a polymer cholesteric liquid crystal laser is prepared. The polymer cholesteric liquid crystal laser can output green laser light. The specific preparation process includes:

[0031] S1. Under yellow light conditions, take 93.35 parts by mass of liquid crystal monomer HCM-006, 3.26 parts by mass of chiral dopant RM257, 1 part by mass of surfactant 2-ethyl methacrylate and 1 part by mass of The photoinitiator IRG651 (benzoin dimethyl ether) was dissolved in xylene at 1.1% by mass fraction, stirred evenly for 1 hour at 40°C in a brown bottle, and prepared into a liquid crystal mixture;

[0032]S2. Take a clean and transparent indium tin oxide conductive glass substrate (ITO substrate), spin-coat 5 parts by mass of polyvinyl alcohol aqueous solution, anneal at 60°C for 1 hour, cool down to room temperature, and rub in one direction with a velvet cloth A transparent substrate coated with a polyvinyl alcohol aqueous solution to form a light-transmitting c...

Embodiment 2

[0040] In this embodiment, a polymer cholesteric liquid crystal laser is prepared, which can output blue laser light. The specific preparation process includes:

[0041] S1. Under yellow light conditions, take 93.1 parts by mass of liquid crystal monomer HCM-006, 3.56 parts by mass of chiral dopant RM257, 1 part by mass of surfactant 2-ethyl methacrylate and 1 part by mass of The photoinitiator IRG651 (benzoin dimethyl ether) was dissolved in xylene at 1.1% by mass fraction, stirred evenly for 1 hour at 40°C in a brown bottle, and prepared into a liquid crystal mixture;

[0042] S2. Take a clean and transparent indium tin oxide conductive glass substrate (ITO substrate), spin-coat 5 parts by mass of polyvinyl alcohol aqueous solution, anneal at 60°C for 1 hour, cool down to room temperature, and rub in one direction with a velvet cloth A transparent substrate coated with a polyvinyl alcohol aqueous solution to form a light-transmitting conductive substrate with parallel alignm...

Embodiment 3

[0047] In this embodiment, a polymer cholesteric liquid crystal laser is prepared. The polymer cholesteric liquid crystal laser can output red laser light. The specific preparation process includes:

[0048] S1. Under yellow light conditions, take 95.0 parts by mass of liquid crystal monomer HCM-006, 3.0 parts by mass of chiral dopant RM257, 1 part by mass of surfactant 2-ethyl methacrylate and 1 part by mass of The photoinitiator IRG651 (benzoin dimethyl ether) was dissolved in xylene at 1.1% by mass fraction, stirred evenly for 1 hour at 40°C in a brown bottle, and prepared into a liquid crystal mixture;

[0049] S2. Take a clean and transparent indium tin oxide conductive glass substrate (ITO substrate), spin-coat 5 parts by mass of polyvinyl alcohol aqueous solution, anneal at 60°C for 1 hour, cool down to room temperature, and rub in one direction with a velvet cloth A transparent substrate coated with a polyvinyl alcohol aqueous solution to form a light-transmitting cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com