High-molecular nanoparticle agent and preparation method thereof

A nanoparticle and polymer technology, applied in coatings, conductive coatings, etc., can solve problems such as gel, poor conductivity, and high cost, and achieve the effects of reducing modification reaction conditions, enhancing corrosion resistance, and enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

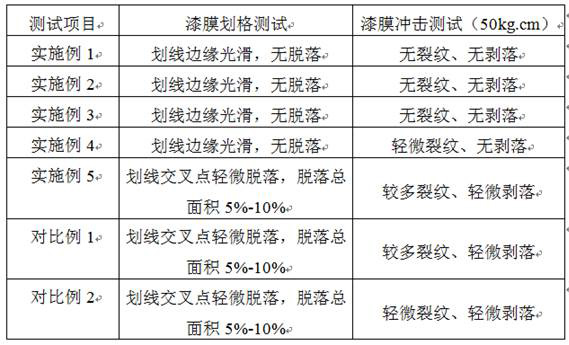

Embodiment 1

[0048] A kind of macromolecule nanoparticulate agent, is made up of following raw material: 200g of bishydroxyl functional silicone modified acrylic resin, 120g of silane coupling agent modified nano silicon dioxide, 38g of dehydrated alcohol, 45g of water-soluble hydrogen-containing silicone oil, twelve Sodium alkylbenzenesulfonate 4g, fluorine-modified polyacrylate leveling agent 5g, film-forming agent 19g, hydrogen peroxide 7g, acetic acid 5g, ammonia 7g, water 550g.

[0049] The film-forming agent is mixed with potassium fluorotitanate and maleic acid in a mass ratio of 16:3.

[0050] The preparation method of the silane coupling agent modified nano-silica comprises the following steps: mixing nano-silica, R-8204 functional polysiloxane, and toluene at a mass ratio of 30:9:100, and mixing them at 10000r / m Stir at min speed for 2 minutes, reflux at 150° C. for 24 hours, wash and dry after cooling to obtain the silane coupling agent-modified nano-silica.

[0051] The prepar...

Embodiment 2

[0058] It is basically the same as Embodiment 1, the difference is only in:

[0059] The double hydroxyl functional group organosilicon-modified acrylic resin is replaced by organosilicon, the preparation method of described organosilicon-modified acrylic resin comprises the following steps: adding 6.25g organosilicon, 0.25g initiator to 20g butyl acetate and mixing uniformly, Stir at 160r / min at 70°C for 5min; then add 25.6g of acrylate and 5g of acrylic acid and react at a constant temperature of 80°C for 1h, filter the precipitate, wash and dry to obtain the silicone-modified acrylic resin.

[0060] The organosilicon is vinyltrimethoxysilane

[0061] The acrylate is mixed with hydroxypropyl acrylate and n-butyl methacrylate in a mass ratio of 9:5.5.

[0062] The initiator is ZIF-8.

Embodiment 3

[0064] It is basically the same as Embodiment 1, the difference is only in:

[0065] The preparation method of the dihydroxy functional silicone-modified acrylic resin comprises the following steps: adding 6.25 g of dihydroxy functional silicone and 0.25 g of initiator to 20 g of butyl acetate and mixing them evenly, and rotating at 160 r / min at 70° C. Stir for 5 min; then add 25.6 g of acrylate and 5 g of acrylic acid and react at a constant temperature of 80° C. for 1 h, filter to collect the precipitate, wash and dry to obtain the bishydroxy functional silicone-modified acrylic resin.

[0066] The acrylate is hydroxypropyl acrylate.

[0067] The initiator is ZIF-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com