Preparation method of lithium ion battery negative electrode material hollow porous vanadium pentoxide microspheres

A technology of vanadium pentoxide microspheres and lithium ion batteries, applied in vanadium oxide, battery electrodes, secondary batteries, etc., can solve the problem of reducing the advantages of three-dimensional hollow microsphere structure, poor material cycle stability, and low specific surface area. and other problems, to achieve excellent rate performance and cycle stability, overcome the thin shell thickness or easy collapse, and the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

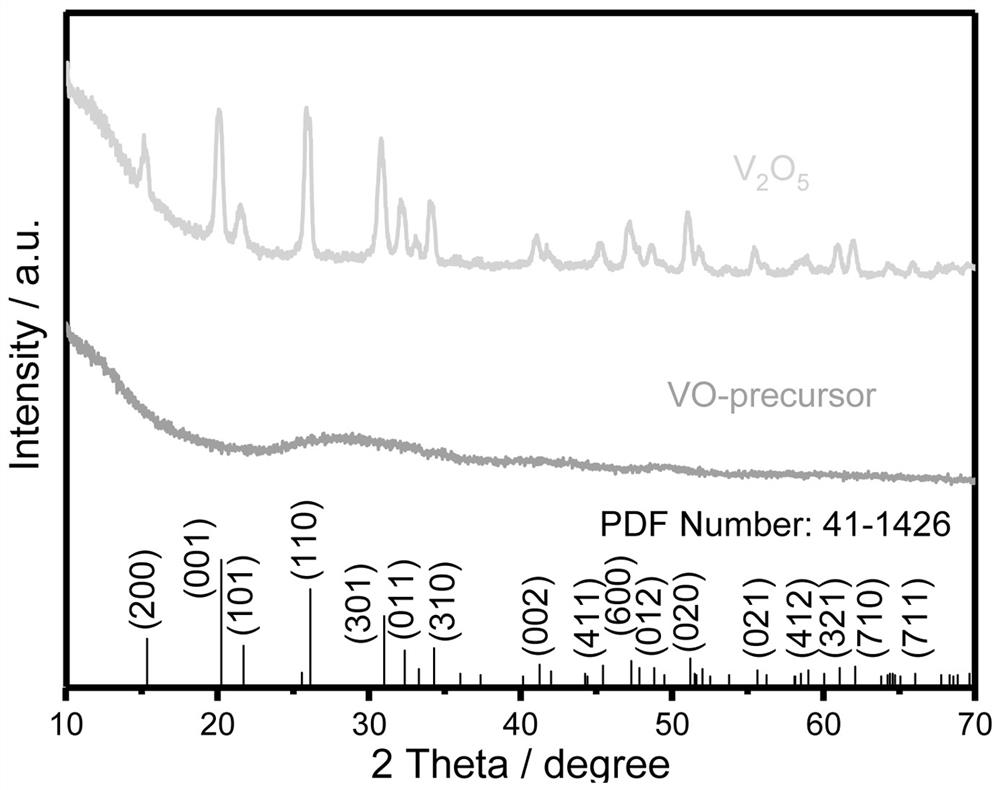

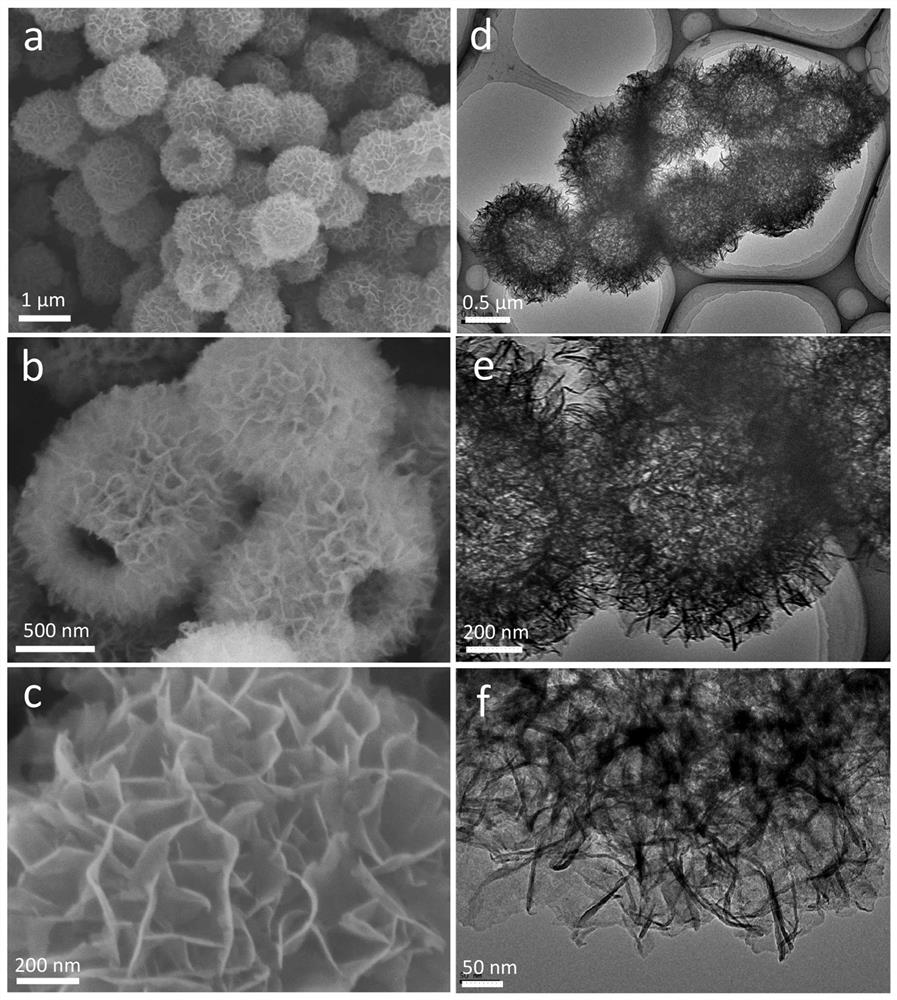

[0029] (1) Add 0.4g of vanadium pentoxide and 1.27g of citric acid into 40 mL of deionized water, stir at 80°C for 0.5h to obtain a 0.11 mol / L vanadyl citrate solution; take 3 mL of vanadyl citrate solution Add it to 30mL of n-propanol and ethylene glycol mixed solvent with a volume ratio of 1:1, stir and mix evenly at room temperature, react in an autoclave at 200°C for 18h, after natural cooling, separate the solid and liquid, and wash with ethanol After drying, a dark green powder is obtained, which is the VO organic ligand precursor.

[0030] (2) The VO organic ligand precursor was heat-treated in air at a heating rate of 4° / min to 400°C for 1 hour. After natural cooling, the product was collected to obtain three-dimensional hollow porous vanadium pentoxide microspheres.

[0031] (3) Preparation of lithium-ion battery electrode pole piece for testing: three-dimensional hollow porous vanadium pentoxide microsphere active material, conductive agent acetylene black and binder...

Embodiment 2

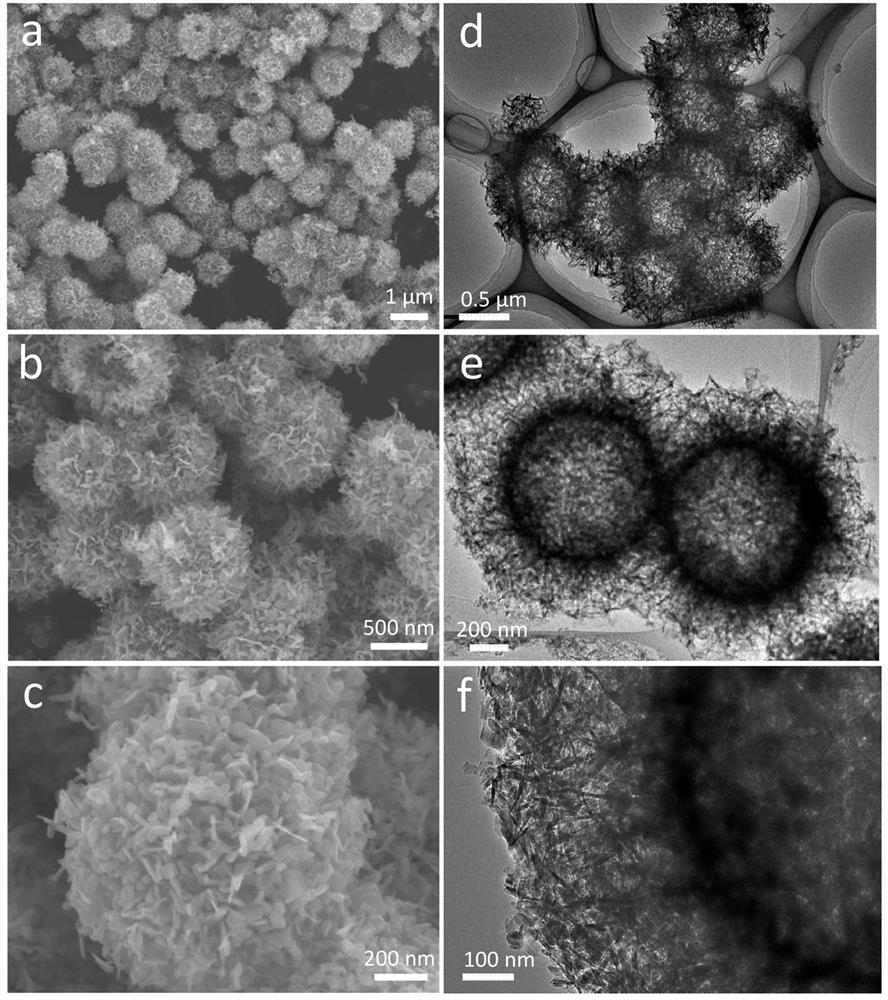

[0039] (1) Add 0.4 g of commercial vanadium pentoxide and 1.27 g of citric acid into 40 mL of deionized water, stir at 80°C for 0.5 h to obtain a 0.11 mol / L vanadyl citrate solution; take 3 mL of vanadyl citrate Add the solution into 30mL of n-propanol and ethylene glycol mixed solvent with a volume ratio of 1:1, stir and mix evenly at room temperature, and react in an autoclave at 200°C for 6h. After natural cooling, solid-liquid separation, ethanol After washing and drying, a dark green powder is obtained, which is the precursor of VO organic ligand.

[0040] (2) The VO organic ligand precursor was heat-treated in air at a heating rate of 4° / min to 400°C for 1 hour. After natural cooling, the product was collected to obtain three-dimensional vanadium pentoxide microspheres.

[0041] (3) Preparation of lithium-ion battery electrode pole pieces for testing: the three-dimensional vanadium pentoxide microsphere active material, conductive agent acetylene black and binder polyvin...

Embodiment 3

[0045] (1) Add 0.4 g of commercial vanadium pentoxide and 1.27 g of citric acid into 40 mL of deionized water, stir at 80°C for 0.5 h to obtain a 0.11 mol / L vanadyl citrate solution; take 3 mL of vanadyl citrate Add the solution into 30mL ethylene glycol solvent, stir and mix evenly at room temperature, react in an autoclave at 200°C for 18 hours, after natural cooling, separate solid-liquid, wash and dry with ethanol, and obtain a dark green powder, which is VO organic ligand precursor.

[0046] (2) The VO organic ligand precursor was heat-treated in air at a heating rate of 4° / min to 400°C for 1 hour. After natural cooling, the product was collected to obtain three-dimensional vanadium pentoxide microspheres.

[0047] (3) The preparation, assembly and electrochemical performance test conditions of the lithium-ion battery electrode pole piece described in Example 1 were adopted.

[0048] Figure 7 Scanning electron microscope (a) and transmission electron microscope (b) ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com