High-strength super-wear-resistant flame-retardant waterproof coiled material as well as preparation method and application thereof

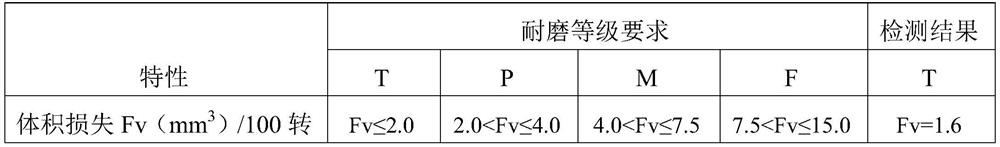

A waterproof membrane, ultra-wear-resistant technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem of increasing the production cost of PVC waterproof membrane, failing to improve the strength and flame retardancy, and the use of physical properties Time reduction and other issues, to achieve the effect of easy cleaning and maintenance, good flame retardant and anti-aging effects, and good covering function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

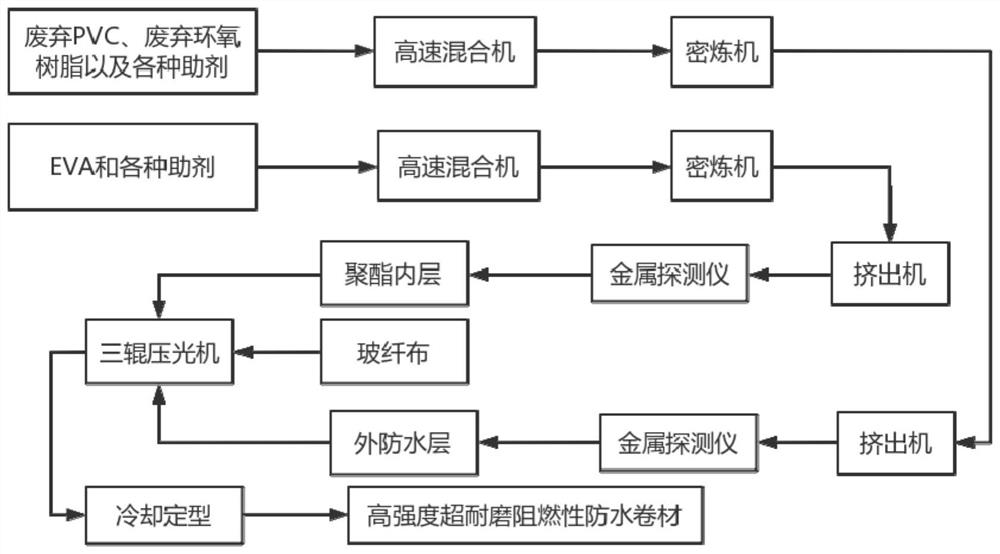

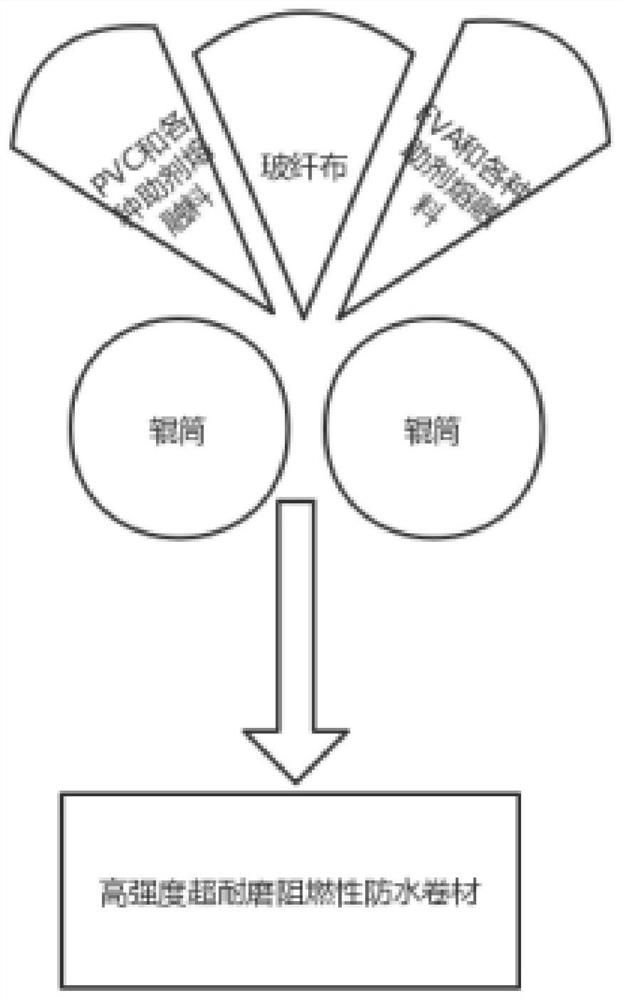

[0047] A preparation method of high-strength super wear-resistant flame-retardant waterproof roll material, such as figure 1 and figure 2 , including the following steps:

[0048] (1) Use waste epoxy resin, polyvinyl chloride reclaimed material, heat stabilizer, light stabilizer, antioxidant, plasticizer, nano flame retardant and antistatic agent with an amount of 0.5-1% polyvinyl chloride reclaimed material The agent is added into the high-speed mixer in the order of solid first and then liquid for mixing and stirring. The temperature is controlled at 130-150°C, the stirring time is about 3.5-4min, and the stirring speed is about 500-900r / min. After mixing evenly, the outer waterproof layer material is obtained;

[0049] Add polyester, antistatic agent and heat stabilizer with an amount of 0.5-1% of polyester into the high-speed mixer in the order of solid first and then liquid, and mix and stir. The temperature is controlled at 130-150°C, and the stirring time is about 3.5...

Embodiment 1

[0067] (1) Waste epoxy resin, recycled material PVC, heat stabilizer - liquid calcium / zinc composite stabilizer, light stabilizer - 2-(2ˊ-hydroxyl-5ˊ-methylphenyl)benzotriazole , Antioxidant - tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, plasticizer - dioctyl phthalate, nano flame retardant - ——Nano hydrotalcite and antistatic agent—polyether amide imide, whose dosage is 0.5% of recycled polyvinyl chloride, are added into the high-speed mixer in the order of solid first and then liquid, and the temperature is controlled at 130°C. The time is about 3.5 minutes, the stirring speed is about 500r / min, and the outer waterproof layer material is obtained after mixing evenly;

[0068] Ethylene-vinyl acetate copolymer, antistatic agent with an amount of 0.5% ethylene-vinyl acetate copolymer-polyethylene oxide and heat stabilizer-liquid calcium / zinc composite stabilizer, in the order of solid first and then liquid Put it into a high-speed mixer fo...

Embodiment 2

[0088] Compared with Example 1, the mixing temperature of recycled PVC, waste epoxy resin and various additives in step (1) was changed from 130° C. to 140° C., and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com