Method for preparing non-layered two-dimensional transition metal compound by using bulk phase layered transition metal sulfide

A transition metal and sulfide technology, which is applied in the field of two-dimensional material preparation technology, can solve the problems that do not conform to the development direction of green scale, increase ammonia gas absorption devices, and be difficult to scale preparation, so as to reduce synthesis costs and achieve high purity. , the effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing two-dimensional molybdenum nitride nanosheets by using bulk molybdenum disulfide, comprising the steps of:

[0065] 1) The commercially available molybdenite concentrate (MoS 2 ) powder and anhydrous sodium carbonate in a molar ratio of 1:2 and then placed in a mortar and grinded fully; transferred to the crucible;

[0066] 2) Put the crucible in step 1) into a tube furnace, heat it to 700° C. for 3 hours at a heating rate of 5° C. / min under an argon protective atmosphere, and cool to room temperature;

[0067] 3) Add the reaction product obtained in step 2) to 1M HCl solution, wash and stir for 2 hours, then repeatedly wash with deionized water until the pH is 7, filter with suction, and finally vacuum dry for 12 hours to obtain two-dimensional molybdenum nitride with good dispersibility Nanosheets.

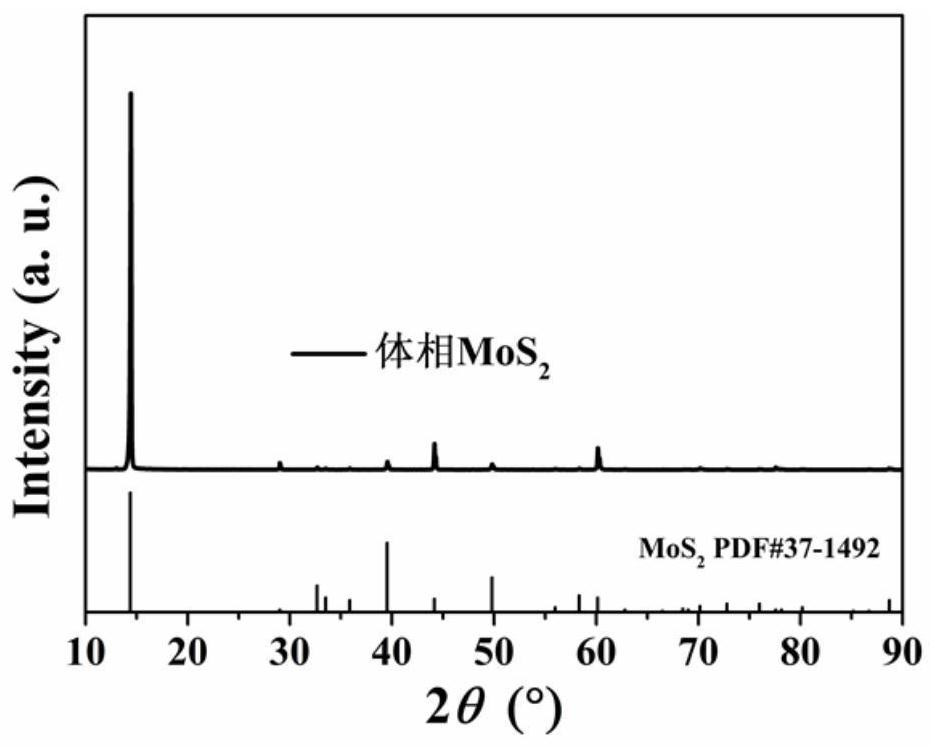

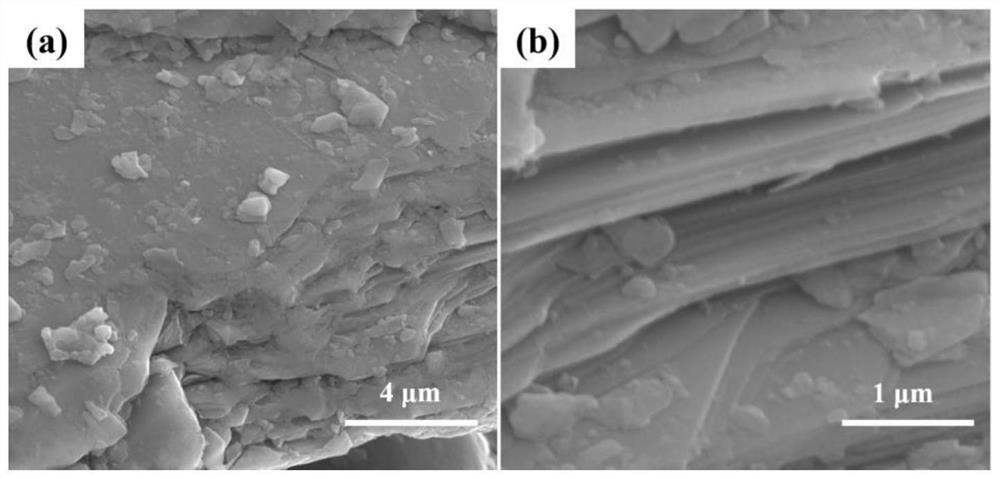

[0068] In this example, the MoS used 2 The bulk powder is commercially available molybdenite concentrate (MoS 2 ) powder, its XRD pattern and ...

Embodiment 2

[0072] A method for preparing two-dimensional molybdenum nitride nanosheets by using bulk molybdenum disulfide, comprising the steps of:

[0073] 1) The commercially available molybdenite concentrate (MoS 2 ) powder and anhydrous sodium carbonate in a molar ratio of 1:2 and then placed in a mortar and grinded fully; transferred to the crucible;

[0074] 2) Put the crucible in step 1) into a tube furnace, heat it to 700° C. for 3 hours at a heating rate of 5° C. / min under an argon protective atmosphere, and cool to room temperature;

[0075] 3) Add the reaction product obtained in step 2) to 1M HCl solution, wash and stir for 2 hours, then repeatedly wash with deionized water until the pH is 7, filter with suction, and finally vacuum dry for 12 hours to obtain two-dimensional molybdenum nitride with good dispersibility Nanosheets.

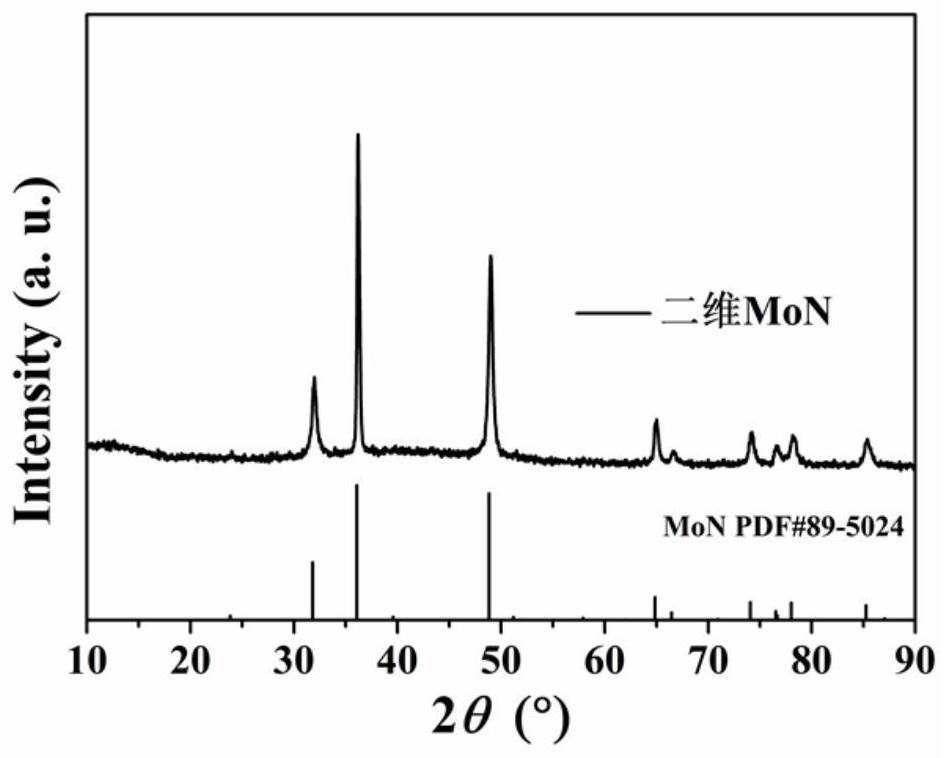

[0076] Figure 5For the other conditions of Example 1, the SEM morphology and XRD diagrams when only the molar ratio of urea and molybdenum dis...

Embodiment 3

[0086] A method for preparing two-dimensional molybdenum nitride nanosheets by using bulk molybdenum disulfide, comprising the steps of:

[0087] 1) The commercially available molybdenite concentrate (MoS 2 ) powder and anhydrous sodium carbonate in a molar ratio of 1:3 and then placed in a mortar and ground thoroughly; transferred to the crucible;

[0088] 2) Put the crucible in step 1) into a tube furnace, heat it to 800° C. for 3 hours at a heating rate of 5° C. / min under an argon protective atmosphere, and cool to room temperature;

[0089] 3) Add the reaction product obtained in step 2) to 1M HCl solution, wash and stir for 2 hours, then repeatedly wash with deionized water until the pH is 7, filter with suction, and finally vacuum dry for 12 hours to obtain two-dimensional molybdenum nitride with good dispersibility Nanosheets.

[0090] Figure 8 For Example 1 commercially available MoS 2 The SEM morphology and XRD patterns when the molar ratio of powder and anhydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com