Ion retention agent, fruit cracking prevention water-soluble fertilizer and preparation method of water-soluble fertilizer

A technology of retaining agent and water-soluble fertilizer, applied in the field of ion retaining agent and anti-cracking fruit water-soluble fertilizer and preparation thereof, can solve the problems of unsatisfactory effect of reducing fruit cracking rate, easy damage to water and fertilizer application equipment, high storage and transportation cost, and achieves good water solubility. , The effect of scientific nutrient distribution ratio and stable fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

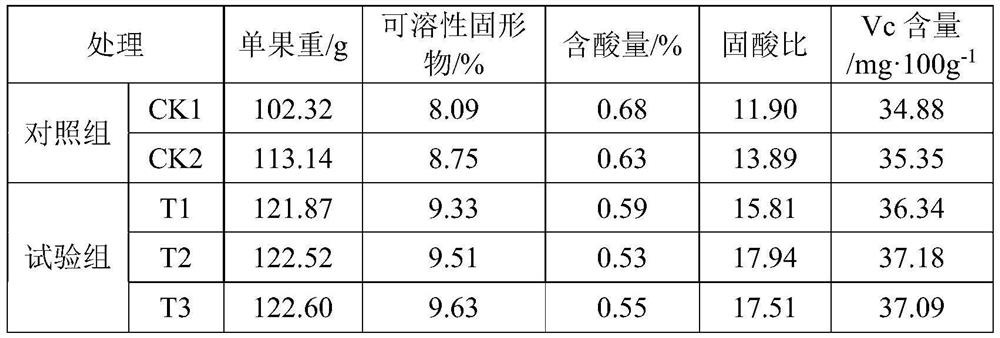

Embodiment 1

[0027] The ion retaining agent in this example is composed of citric acid, cetylpyridinium bromide, polyasparagine, and sodium lignosulfonate at a mass ratio of 1:1:2:3.

[0028] The citrus anti-cracking fruit water-soluble fertilizer in the present embodiment is mixed by the following raw materials in parts by weight: 20 parts of urea, 10 parts of industrial monoammonium phosphate, 40 parts of potassium nitrate, 5 parts of calcium nitrate, 5 parts of magnesium sulfate, compound chelate 2 parts of trace elements and 0.3 parts of ion retaining agent; among them, the compound chelated trace elements are composed of ferrous sulfate, copper sulfate, EDTA-Zn, four water eight Sodium borate, manganese sulfate, ammonium molybdate and amino acid are prepared by chelation reaction.

[0029] The preparation method of the citrus anti-cracking fruit water-soluble fertilizer in the present embodiment comprises the following steps:

[0030] (1) Weighing: Weigh each raw material component a...

Embodiment 2

[0036] The ion retaining agent in this example is composed of citric acid, cetylpyridinium bromide, polyasparagine, and sodium lignosulfonate at a mass ratio of 2:3:3:5.

[0037] The citrus anti-cracking fruit water-soluble fertilizer in the present embodiment is mixed by the following raw materials in parts by weight: 40 parts of urea, 20 parts of industrial monoammonium phosphate, 50 parts of potassium nitrate, 10 parts of calcium nitrate, 10 parts of magnesium sulfate, compound chelate 5 parts of trace elements, 1.5 parts of ion retaining agent; among them, the compound chelated trace elements are composed of ferrous sulfate, copper sulfate, EDTA-Zn, four water eight Sodium borate, manganese sulfate, ammonium molybdate and amino acid are prepared by chelation reaction.

[0038] The preparation method of the citrus anti-cracking fruit water-soluble fertilizer of this embodiment, the preparation steps are the same as in Embodiment 1.

[0039] The pH of the citrus anti-cracki...

Embodiment 3

[0041] The ion retaining agent in this example is composed of citric acid, cetylpyridinium bromide, polyasparagine, and sodium lignosulfonate at a mass ratio of 1.5:2:2.5:4.

[0042] The citrus anti-cracking fruit water-soluble fertilizer of the present embodiment is mixed by the raw materials of following parts by weight: 30 parts of urea, 15 parts of industrial monoammonium phosphate, 45 parts of potassium nitrate, 7.5 parts of calcium nitrate, 7.5 parts of magnesium sulfate, compound chelated trace 3.5 parts of element components, 0.9 parts of ion retaining agent; wherein, the composite chelated trace elements are composed of ferrous sulfate, copper sulfate, EDTA-Zn, tetrahydrate Sodium octaborate, manganese sulfate, ammonium molybdate and amino acid are prepared by chelation reaction.

[0043]The preparation method of the citrus anti-cracking fruit water-soluble fertilizer of this embodiment, the preparation steps are the same as in Embodiment 1.

[0044] The pH of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com