Method for preparing iron and separating vanadium and titanium from vanadium titano-magnetite through calcium-free low-temperature reduction

A vanadium-titanium magnetite and separation method technology, applied in the direction of improving process efficiency, etc., can solve problems such as erosion, unsuitable use, and lower economic efficiency, and achieve the effects of reducing smelting sulfur load, reducing coal powder consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

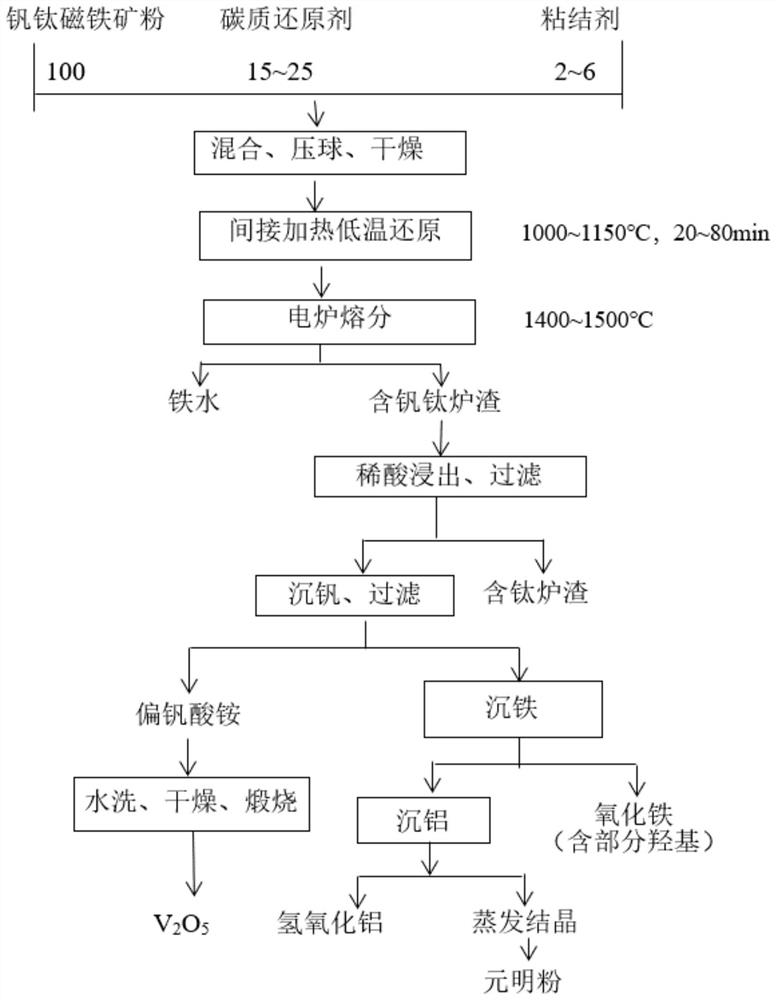

[0068] This embodiment provides a calcium-free low-temperature reduction of vanadium-titanium magnetite to prepare iron and vanadium-titanium separation method, using the above-mentioned method, the process flow diagram is as follows figure 1 shown. The specific details are as follows:

[0069] The vanadium-titanium-magnetite powder (particle size: 50-100 mesh) used in this example has main components shown in Table 1. Coal powder for reducing agent is shown in Table 2, and the binder is an organic binder, such as waste syrup.

[0070] Vanadium-titanium-magnetite powder, coal powder, and binder are mixed according to the mass ratio of 100:20:3, mixed, and cold-pressed to obtain pellets. The pellets are ellipsoids with a particle size of 30-50mm. Dry on a continuous dryer, the drying air temperature is 300°C, stay for 30min, and the moisture content of the pellets is 1.8%.

[0071] The pellets enter the indirect heating reduction device for reduction, the thickness of the ma...

Embodiment 2

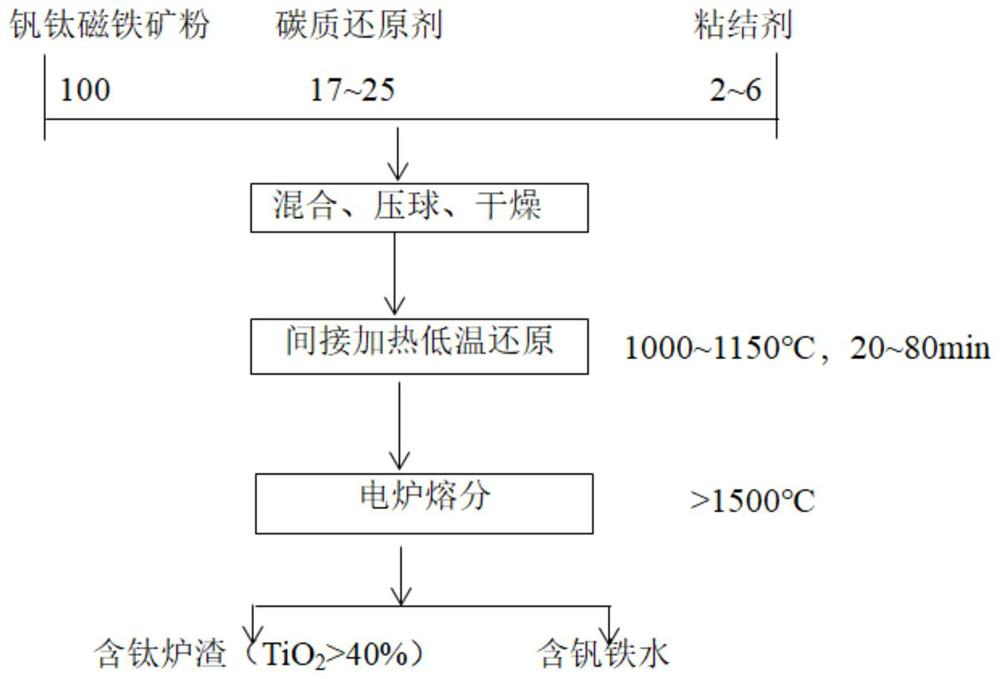

[0081] This embodiment provides a calcium-free low-temperature reduction of vanadium-titanium magnetite to prepare iron and vanadium-titanium separation method, using the above-mentioned method, the process flow diagram is as follows figure 2 shown. The specific details are as follows:

[0082] The vanadium-titanium-magnetite powder (particle size: 50-100 mesh) used in this example has main components shown in Table 1. The coal powder used as the reducing agent is shown in Table 2, and the binder is an organic binder, such as sodium carboxymethylcellulose.

[0083] Vanadium-titanium-magnetite powder, carbonaceous reducing agent, and binder are mixed according to the mass ratio of 100:22:3, mixed, and cold-pressed to obtain pellets. The pellets are ellipsoids with a particle size of 30-50mm. Dry on a continuous dryer, the drying air temperature is 300°C, stay for 30min, and the moisture content of the pellets is 1.8%.

[0084] The pellets enter the indirect heating reductio...

Embodiment 3

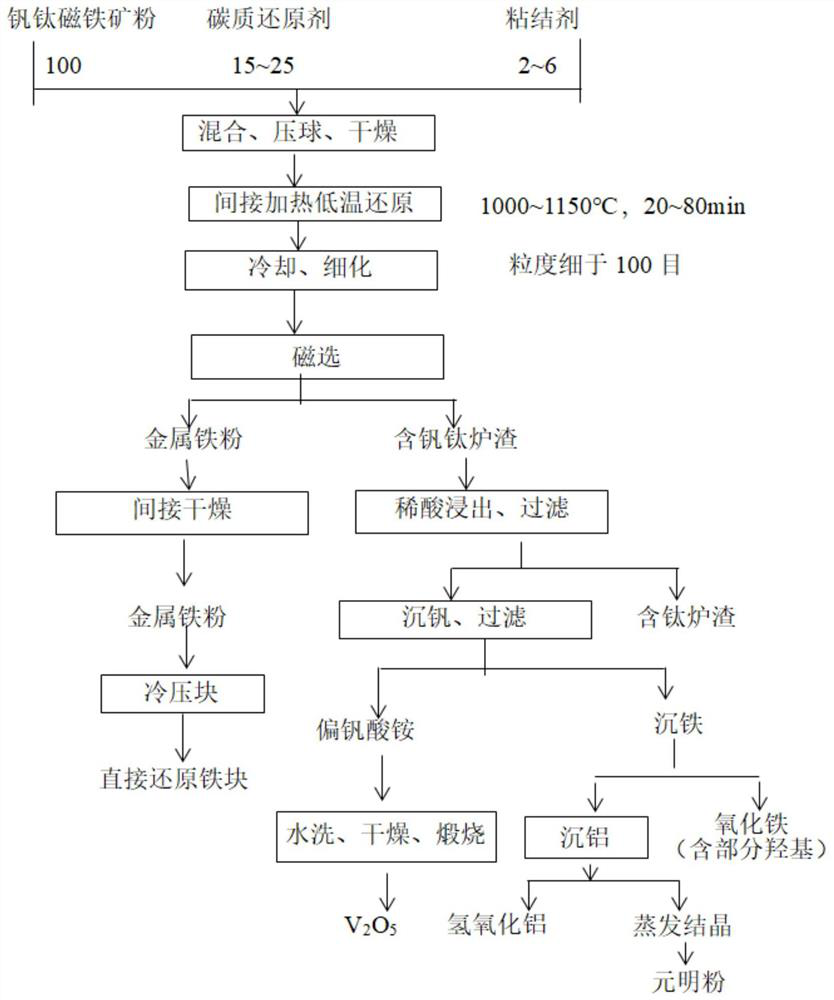

[0087] This embodiment provides a calcium-free low-temperature reduction of vanadium-titanium magnetite to prepare iron and vanadium-titanium separation method, using the above-mentioned method, the process flow diagram is as follows image 3 shown. The specific details are as follows:

[0088] Vanadium-titanium magnetite powder, reducing agent and binding agent addition, mixing, ball pressing, drying and reduction parameters are the same as in Example 1.

[0089] The metallized pellets obtained after the reduction of the pellets are cooled and refined to a finer size of 100 mesh or less, and the slag and iron are separated by a magnetic separator.

[0090] The obtained iron powder is subjected to indirect drying (300°C, 30min) to control the water content below 3% and dehydrate to obtain metal iron powder with 93% total iron and 0.25% V, and cold press the metal iron powder into direct reduced iron nuggets. Add to converter, electric furnace or blast furnace.

[0091] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com