Self-cleaning super-hydrophobic conversion film on metal matrix, preparation method and film-forming agent of self-cleaning super-hydrophobic conversion film

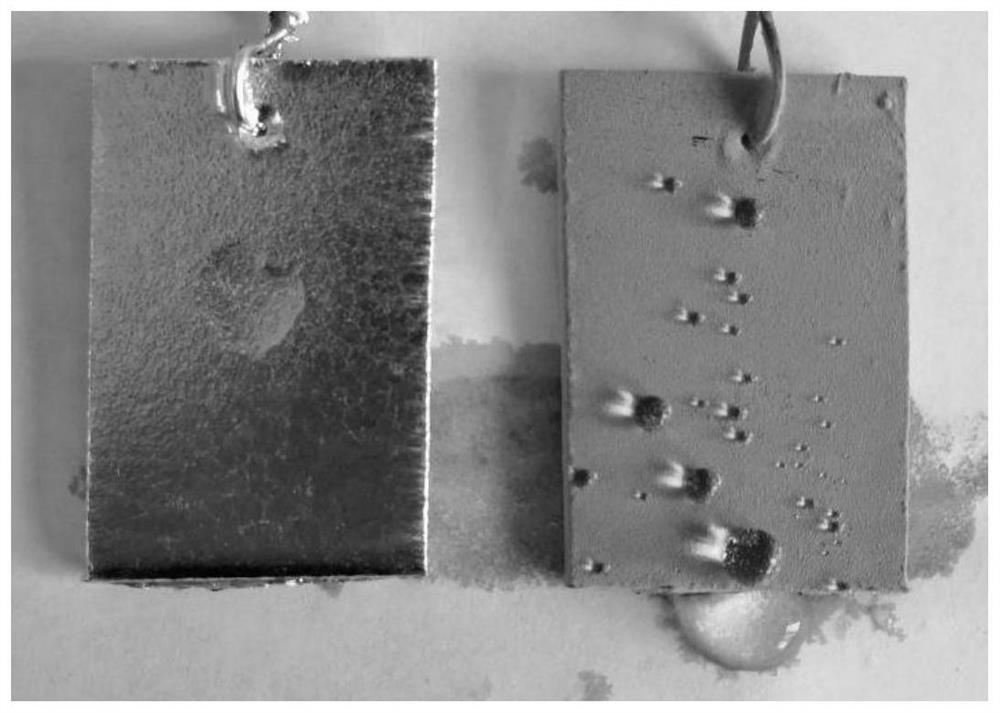

A metal substrate and conversion film technology, applied in the direction of metal material coating process, etc., can solve the problems of passive film not self-healing, restricting large-scale production and development, long-term protection of difficult metals, etc., to achieve good self-cleaning resistance, good protective effect, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

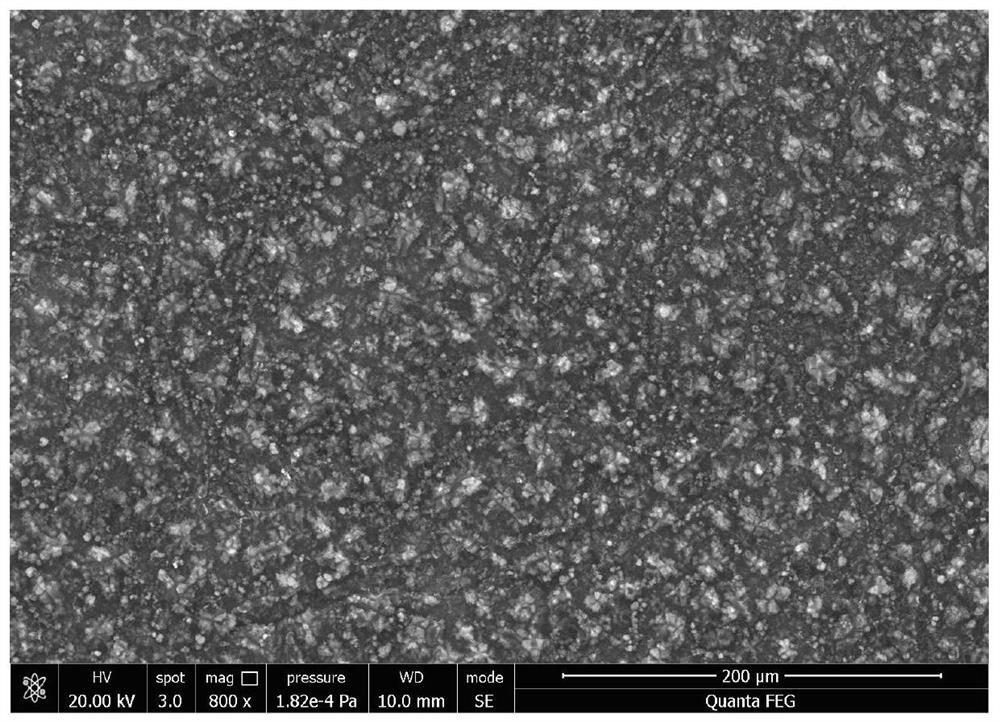

[0046] This embodiment is a self-cleaning superhydrophobic conversion film with a blue appearance, and its preparation method comprises the following steps:

[0047] In the first step, vinyltrimethoxysilane, ethanol, and deionized water are mixed in a ratio of 4:6:90, and magnetic stirring is applied for 1 hour, and hydrolyzed for at least 48 hours to obtain a hydrolyzed silica sol;

[0048] In the second step, a certain amount of corrosion inhibitor (lanthanum nitrate), surface energy regulator (myristic acid), film-forming accelerator (hydrogen peroxide), and ion auxiliary agent (copper sulfate) are added to the hydrolyzed In the silica sol, it is fully dissolved by magnetic stirring to form a transparent and uniform composite film-forming solution. Finally, the pH value of the above solution is adjusted to 3-5 with a pH regulator to obtain a film-forming agent for conversion film. The content of each component in the film-forming agent in the present embodiment is:

[0049...

Embodiment 2

[0059] The preparation method in this implementation is different with embodiment 1, and the film-forming liquid composition in the embodiment is different:

[0060] In the first step, mix methyltrimethoxysilane, ethanol, and deionized water in a ratio of 4:6:90, apply magnetic stirring for 1 hour, and let stand for hydrolysis for at least 48 hours to obtain a hydrolyzed silica sol;

[0061] In the second step, a certain amount of corrosion inhibitor (cerium nitrate), surface energy modifier (stearic acid), film-forming accelerator (hydrogen peroxide), and ion auxiliary agent (copper nitrate hexahydrate) are added to the pre- The hydrolyzed silica sol is fully dissolved by magnetic stirring to form a transparent and uniform composite film-forming solution, and finally the pH of the solution is adjusted to 3-5 with 4% nitric acid to obtain a film-forming agent for conversion film.

[0062] The third step is to immerse the pretreated clean galvanized steel sample in the prepared...

Embodiment 3

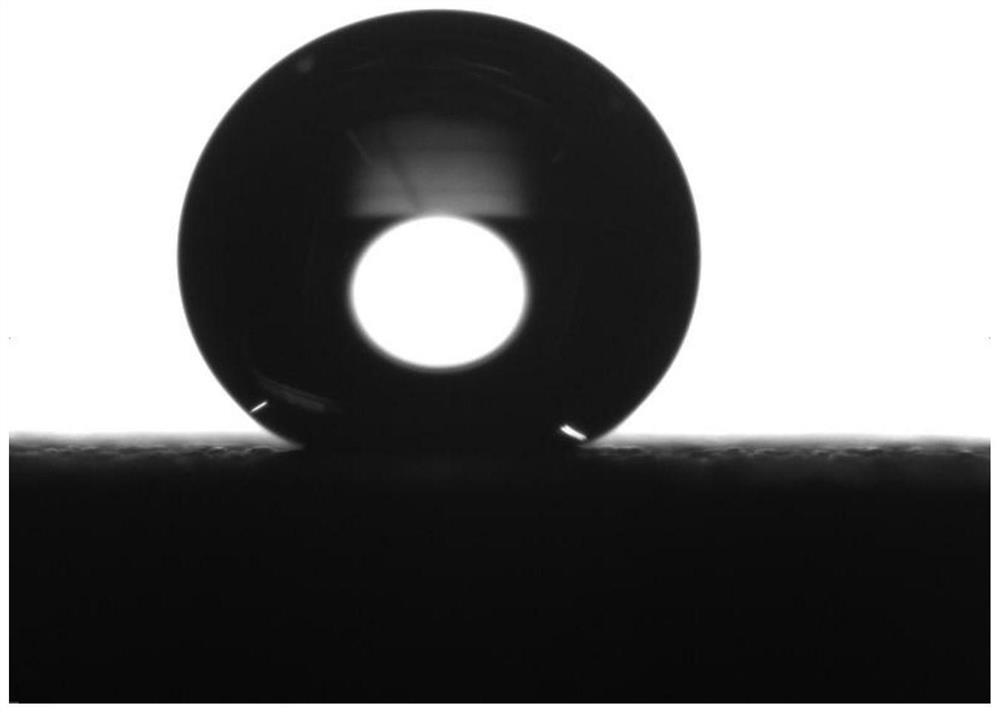

[0065] The matrix material selected in this embodiment is a hot-dip galvanized aluminum alloy (Galfan) steel plate. By following the conversion coating preparation method in Example 1, a superhydrophobic self-cleaning film with a blue appearance is prepared on the surface of a hot-dip galvanized aluminum alloy steel plate. surface. The contact angle of water droplets on the surface of the hot-dip Galfan alloy conversion coating is greater than 150°, and the rolling angle is less than 10°, which has good self-cleaning performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com